Smarter Machining Squeezes More Productivity And Profits From The Shop Floor

To increase efficiency and productivity, this Canadian mold shop began programming NC cutter paths on the shop floor, in real time.

Reko International Group, Inc. (Oldcastle, Ontario, Canada) designs and manufactures plastic injection, compression and lost core molds (both prototypes and production), custom machining, automation, fixtures and special machines, metal stamping dies (both prototype and production), and CNC machining centers for automotive, consumer and industrial products, and aerospace industries.

In 1995, Reko's leadtime for building molds needed to be reduced, so the company had to improve the efficiency and throughput of its NC programming process. The company had eight NC programmers programming up to ten CNC surface cutting machines.

To increase efficiency and productivity, Reko began programming NC cutter paths on the shop floor, in real time. Once CAD data is complete and ready to manufacture, it is reviewed by a CAM coordinator and sent to the shop floor. Machining normally starts within in a day. The machine operator does NC programming in real time at the machine. Parts are roughed to 0.100/side stock and then sent for thermal stress relief, followed by semi (0.03/side stock) and finish machining.

The move to shopfloor programming enabled the company to meet compressed lead times. Today, Reko has more than 500 employees, 55 CNC machines, 100 experienced NC/CNC programmers and a team of CAM coordinators who prepare the model files and send them to the CNC machines. With the slowing economy, however, Reko has looked to further increase efficiency and squeeze more productivity and profit from the shop floor.

"I used to be an operator, and I stayed at the CNC control, watching and overriding the feed when necessary," says Ernie Stajduhar, machining systems leader. "To improve efficiency, I thought, ‘Why not have software do it instead?'"

Reko selected Vericut software from CGTech (Irvine, California). Vericut simulates the NC machining process to detect errors and correct areas of inefficiency in NC toolpaths.

The software was installed on the shopfloor machine systems where NC code is written. It enables operators to verify the accuracy and integrity of the tool path in real time on the machine. As programs are created, the processed programs are run through the Vericut simulation as the tool path is running on the machine. The verification process stays ahead of the actual machine position in the NC code being verified. Operators can see errors before they occur.

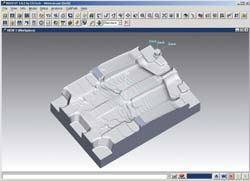

But the main reason Reko purchased the software was its optimization capabilities. Vericut uses a knowledge-based machining technology to select the best feed rate for each cutting condition encountered. During verification, the software virtually "cuts" the part. It updates the stock model as its shape changes throughout material removal. Because the software knows how the cutting operations affect the physical workpiece, it can determine the best feed rates for each segment of the toolpath.

The software knows exactly how much material will be removed at each segment of the toolpath, so it can assign the best possible feed rates. As the cutting tool encounters more material, feed rates decrease; as less material is removed, feed rates speed up. Based on the amount of material removed by each cut segment, the software calculates the best feed rate and inserts it into the tool path. It then creates a new, optimized tool path without changing the trajectory or the original tool path. The software also detects material left behind during the previous operation, which could snap the cutter if undetected.

Programmers at Reko create the tool path at the machine and then load it into Vericut. As the program verifies and optimizes the NC code, it writes an improved tool path that is fed to the CNC on the fly as it is cutting.

The shop used to have a problem with excessive tool breakage, and run times were longer than desired. "Our cutting operations are more efficient now, because we're using the software to control the feed rates," Mr. Stajduhar says. "We're seeing shorter machining times." Reko has reduced its average roughing and semi-finishing machining operations cycle time by 30 percent.

Also, CNC operator productivity has increased. "By using Vericut, we've eliminated having an operator locked at the machine, overriding that feed control knob to run NC cutter paths as efficiently as possible," says Mr. Stajduhar. "This promotes running machines unattended and having operators run more than one machine."

Running machines unattended requires confidence in the accuracy of the tool path and the programmed feed rates. Mr. Stajduhar quickly learned that the feed rates selected by the software were safe and reliable. He recalls an experience that solidified his trust in the software: "The operator was running a rough-pass lace cut program at over 100 ipm, not realizing that the cutter was approaching an area with a lot of stock. Normally, if the cutter encountered that much stock at that feed rate, the tool would break or the job would shift. But the program had been optimized in Vericut, so when the cutter approached the area of heavy stock, it automatically adjusted to 50 ipm and handled the cut without any problems."

A final unexpected benefit is less wear and tear on cutting tools and the CNC itself. Optimized tool paths remove material at a constant chip load, placing more consistent cutting pressure on the tool. A more constant cutting pressure between the machine tool and the workpiece reduces variable forces on the axis motors for smoother machine operation.

Related Content

When Handing Down the Family Machine Shop is as Complex as a Swiss-Turned Part

The transition into Swiss-type machining at Deking Screw Products required more than just a shift in production operations. It required a new mindset and a new way of running the family-owned business. Hardest of all, it required that one generation let go, and allow a new one to step in.

Read MoreAutomated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreAutomating Part Programming Cuts the Time to Engaging Work

CAM Assist cuts repetition from part programming — early users say it could be a useful tool for training new programmers.

Read MoreRead Next

Rego-Fix’s Center for Machining Excellence Promotes Collaboration

The new space includes a showroom, office spaces and an auditorium that will enhance its work with its technical partners.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)