New Systems and Software Products from Modern Machine Shop, Jul. 21, 2020

The latest technology from DP Technology Corp. - ESPRIT, CGTech, and ANCA CNC Machines

EngView's mCaliper App Safely Transfers Manual Measurement Results

EngView’s mCaliper mobile/server application is designed for the safe transfer and storage of measurement results.

EngView’s mCaliper mobile/server application is designed for the safe transfer and storage of measurement results collected from calipers, micrometers and other manual tools. The software supports Bluetooth and USB connection as well as tools with no data output like standard Vernier calipers.

The software was developed in response to working conditions during the COVID-19 pandemic. “Tracking data from quality control tools is important but even more so now, when businesses are working remotely and the collection and monitoring of measurement data is quite difficult,” the company says.

The software consists of a mobile application and a locally installed server, a setup intended to maximize data security. The mobile app is available for download on Google Play for all Android devices of version 6.0 or higher.

The mobile app displays a step-by step measurement plan for a quality control operator to follow. It gives color-coded indications showing if the measured dimensions are in or out tolerance. The plan is based on a CAD drawing or an image and can be prepared within minutes. For each part ID the measurement plan is prepared only once and used for all parts of the same ID. Once measurement is completed, the data is uploaded on a server and stored for further analyses and reporting. Results are reviewed in graphical or table view. Measurement protocols and reports can be generated for a single measurement as well as for a specific part ID over a period of time.

The mCaliper solution can easily be integrated with internal SPC or ERP systems to ensure a streamlined workflow, the company says.

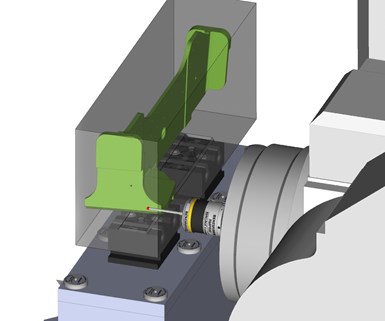

Esprit from DP Technology Gets Added Probing Cycles

DP Technology has added a suite of probing cycles to Esprit CAM software.

DP Technology has added a suite of probing cycles to Esprit CAM software. The new features include:

- Offline inspection programming, which enables virtual simulation for program verification and collision detection

- Hassle-free postprocessing and full control over each probing routine

- Compatibility with more CNC machines and probe manufacturers

These capabilities join the probing cycle’s existing features, including:

- Misload detection, which confirms correct part loading and reduces the risk of damage

- On-machine inspection, which generates consistent measurements and eliminates manual measuring errors

- Dynamic tool offsets, which automatically adapt the program considering tool wear

Using Esprit for CNC machines equipped with touch probes will contribute to increased throughput on existing equipment while reducing operator intervention, the company says.

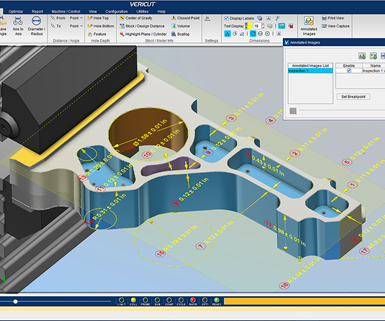

CGTech's Vericut 9.1 Improves CNC Simulation Visibility Options

Version 9.1 of CGTech’s Vericut includes enhancements to toolpath optimization, additive manufacturing, tooling and multi-tool stations, and measuring and inspection.

Version 9.1 of CGTech’s Vericut machine simulation, verification and NC optimization software includes new visibility options and enhancements to toolpath optimization, additive manufacturing, tooling and multitool stations, and measuring and inspection.

Visibility features added to the Project Tree and right-click menus for components and models enable users to toggle between visible and invisible states or to enable/disable 3D objects for the simulation. New features added to AUTO-DIFF likewise give users more control over component visibility, such as when fixture models should appear.

Setup Plan has been renamed Annotated Images. Vericut Inspection is also now included with Annotated Images. Both Setup Plan and inspection functionality provide dimensions, notes and tolerances for checking parts at various stages of machining. Users can create professional and informative setup plans and inspection images stored with view layouts ready to print as shop aid documents or to appear in Vericut’s reports.

Defining shanks as separate objects from the holder and cutter enables programmers to see where these non-cutting portions of the cutter are located relative to the stock workpiece, allowing for more discrete control over near-miss and collision detection properties and tolerances.

A Force “Learn” Mode is now available for optimization, which uses artificial intelligence to learn from the cutting simulation and then automatically configure and optimize tools for increased cutting efficiency and reduced machining times. A Learn From Results option enables optimization settings for a tool or all tools that were analyzed.

Vericut 9.1 has a new “Additive” Default Machining Type, enabling enables the software to predict system resources that will be needed to additively build the as-designed part, including a starting stock build plate or model. Vericut can build multiple parts created by a nested-build NC program, enabling additively built parts to be independently relocated or assembled for finish machining or exported.

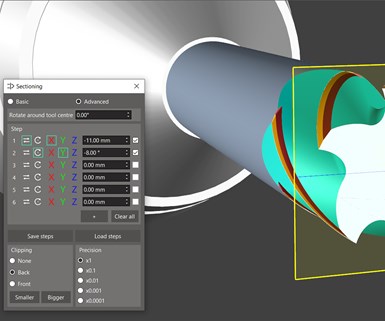

ANCA's CIM3D Tool Grinding Software Enables Remote Programming

Version 9 of ANCA’s CIM3D or CIMulator3D tool grinding simulation software has an upgraded interface with fresh colors and icons for easier use.

Version 9 of ANCA’s CIM3D or CIMulator3D tool grinding simulation software has an upgraded interface with fresh colors and icons for easier use. CIM3D V9 enables customization based on regularly-used features and off-line verification of background calculations, increasing machine productivity. It also enables those working from home to perform programming remotely.

The new version offers clearer visualization with a customizable timeline panel: a central dashboard speeding tool analysis. New tool programs can be verified for size, shape, machine clearance, cycle time estimates and more. Users can determine protrusion length, estimate cycle times, increment position with the mouse’s scrolling function and more.

ECI's Order Snapshot Automates Order Status Updates for Small, Medium-Size Businesses

ECI Software Solutions offers Order Snapshot to its M1 enterprise resource planning (ERP) users.

ECI Software Solutions offers Order Snapshot to its M1 enterprise resource planning (ERP) users. The cloud-based web application enables M1 users to provide customers with detailed visual status information from the moment the order is entered into the system to after shipping. Developed in response to supply chain disruptions caused by the coronavirus pandemic, the system automates what is usually a manual task. Order Snapshot enables tracking of in-transit shipping status with a link. Customer updates can be set to trigger when an order is received, approved, in-process, completed and shipped. Users can design a template with their logo and custom messaging to send to customers when their order status changes.

The cloud infrastructure enables rapid updates and ensure every customer is on the latest version as soon as it is released. It also enables easy access to information from any device and any location, the company says. Administrative rights and customer data are automatically synced between the M1 hosted environment and the Amazon Web Services cloud environment.

Read Next

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreInside Machineosaurus: Unique Job Shop with Dinosaur-Named CNC Machines, Four-Day Workweek & High-Precision Machining

Take a tour of Machineosaurus, a Massachusetts machine shop where every CNC machine is named after a dinosaur!

Read MoreIncreasing Productivity with Digitalization and AI

Job shops are implementing automation and digitalization into workflows to eliminate set up time and increase repeatability in production.

Read More

.jpg;maxWidth=300;quality=90)