How to Measure Special Diameters

More complicated checks sometimes require more versatile measurement systems with long ranges.

Sometimes we are faced with making critical diameter checks on parts that do not present themselves in a straightforward fashion. Usually these checks are on the inside of some type of bearing that can be almost any size. Or they might be on a giant transmission housing large enough to walk through and include measuring the diameter of an internal surface behind a shoulder, where the entry diameter is smaller than the diameter being measured. Or they might require measuring a ring groove in a bore, the pitch diameter of an internal thread, the effective diameter of a barrel roller bearing or the included angle of a tapered bore.

Measuring these types of diameters requires that the gage have some unique characteristics. Depending on the tolerances, having the simple capability to make multiple diameter checks with a very versatile system may be the most critical requirement. Or you may have a situation where tight tolerances demand the high repeatability of a comparative gage, long-range jaw retraction to allow entry into the part, and the ability to set the depth of the contact to make the measurement at the proper point.

Many people immediately think of using a shallow-bore gage for this type of application. As we have discussed in the past, this type of gage rests on the face of the part and measures the inside diameter at a certain depth. These are fairly accurate comparative gages that allow the depth of the contact to be set to a specific location. However, these gages are typically limited by the amount of travel in the indicating device used for the readout. As simple fixed-diameter gages, they work well, but they do not meet the need for long range to get behind a shoulder or to have the contact measure the groove diameter they are generally set to measure. Nor do they have any versatility to check other dimensions.

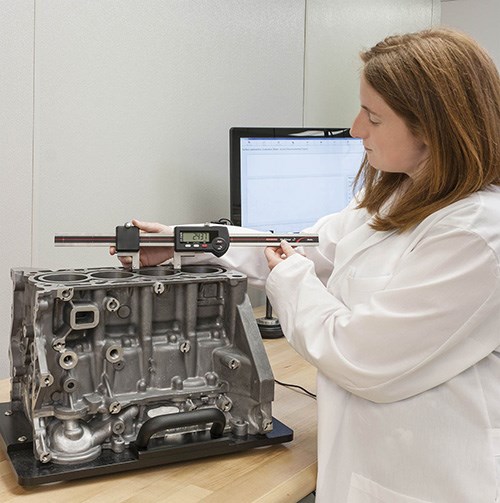

Two types of measuring devices do meet the needs of these types of applications: universal caliper inner diameter/outer diameter gages, and long-range slides coupled with high-resolution, long-range digital indicators.

The universal caliper ID/OD gage is basically just as it sounds: a long digital scale with a readout, but also with two moving slides upon which interchangeable jaws/contacts are mounted. Universal is truly the right term, as this type of measuring instrument allows for the various jaw sets to be mounted on either the top or bottom of the display. No more trying to read upside-down measuring results. The other benefit of this type of arrangement is its versatility. The greatest benefit of any digital caliper is the versatility to measure multiple features. With these universal ID/OD gages, that benefit is compounded, as the increased range allows for expanded capacity. Both jaws can be set anywhere within the range of the tool, allowing it to be well balanced at the point of manufacture.

These long-range universal measuring systems serve a valuable role in the general inspection of large parts that have loose to medium tolerances. However, all caliper gages are subject to some operator influence related to gaging pressure, skill and scale accuracy over the long measuring range.

To take the process up to the next level requires a move to a comparative version of the system using a long-range digital indicator as part of the measuring frame. This has the benefit of actually referencing the measurement based on an external precision reference master—the accuracy built into the digital indicator's precision scale. The combination of the long-range, high-resolution digital indicator and a soundly designed mechanical frame can provide a universal ID (or OD) gage that has endless applications for those hard-to-reach inside measurement applications.

Of course, the contacts must be designed to handle the depth and gaging pressures, but the beauty of this type of gage is that its long range offers the ability to measure any number of depths within that range. So besides measuring a depth at a particular location, it can measure two diameters at different depths, thus becoming a taper gage measuring the included angle of the tapered bore.

Related Content

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read More4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read MoreSelecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

Read More4 Tips for Staying Profitable in the Face of Change

After more than 40 years in business, this shop has learned how to adapt to stay profitable.

Read MoreRead Next

IMTS 2024: Trends & Takeaways From the Modern Machine Shop Editorial Team

The Modern Machine Shop editorial team highlights their takeaways from IMTS 2024 in a video recap.

Read MoreInside Machineosaurus: Unique Job Shop with Dinosaur-Named CNC Machines, Four-Day Workweek & High-Precision Machining

Take a tour of Machineosaurus, a Massachusetts machine shop where every CNC machine is named after a dinosaur!

Read MoreIncreasing Productivity with Digitalization and AI

Job shops are implementing automation and digitalization into workflows to eliminate set up time and increase repeatability in production.

Read More

.jpg;maxWidth=300;quality=90)