Balancing Workholding Density And Flexibility

Like many contract manufacturers and job shops, this company found itself doing runs that were too short for dedicated fixtures and too long for one-vise setups.

Share

The key to success for Matt Machine & Manufacturing, Inc. (Pittsburgh, Pennsylvania) was finding the right balance between high-density and flexible workholding. Like many contract manufacturers and job shops, the company found itself doing runs that were too short for dedicated fixtures and too long for one-vise setups.

The 15-person company specializes in low-volume precision production. The majority of the parts it produces are components for medical equipment, electronic microscopes and other scientific devices. It uses two CNC lathes for turning and five VMCs for milling in its 7,500-square-foot facility.

With long production runs on parts, the company's task was to optimize spindle efficiency while reducing setup time, explains operations manager Mike Jezek. "When you make one or two of a kind, then reducing your setup time is what will give you the edge."

Even with its first machining center, a LeBlond Makino, the company realized that it would be more productive with more parts at the spindle. So right away, the company used two vises on the machine. Although it's no big deal today, general manager Rudy Jezek remembers how amazed everyone was at hearing the machine running in the shop during lunch breaks.

For nearly a decade, the company objective has been to methodically increase the number of parts at the spindle, acheiving high-density workholding without giving up the flexibility of vises. The company took its first step when it added a Hitachi Seki with a pallet changer to the machine park and mounted three vises to each pallet for a total of six parts.

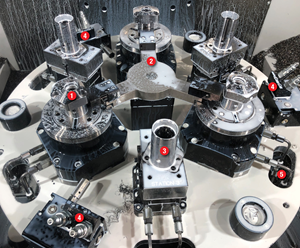

Next, the company equipped each pallet on its Okuma two-pallet VMC with five twin vises from Bock Workholding (Mars, Pennsylvania) mounted on a Bock locator plate. This increased the total number of parts in the machine to 20.

"We bought this system because it met our need for density and flexibility," says Mike Jezek. "On the density side, the Bock twin vises can hold two parts relatively big for their size. On the flexibility side, they have enough jaw travel for a good range of part sizes, and they can be relocated on the pallet very quickly and accurately."

Increasing density and flexibility were the driving forces behind the acquisition of all the machining centers. The company also has a Haas VF-1 with a fourth axis, a Haas VF-6 with a 64- by 3-inch table and an Okuma MA-60 HMC. The Okuma's six pallets are equipped with Bock Multi-Quad 6.16 systems, each one capable of holding up to 16 parts for a total load of 96 parts.

Before they go home for the evening, employees load up the machine, which produces two additional shifts without having anyone there. The typical workload of the machine is a mix of jobs, and each job has its own set of tools in the magazine. If the machine's probe detects a tooling problem, it will bypass the production of only one part and continues to make chips on the others.

With dedicated fixtures the machines could probably have a few more parts, but for the company it makes more sense to have a workholding system that lets machines change quickly from one job to another, says Mike Jezek.

Most job-shop and contract manufacturing environments require the least amount of setup time possible. If kept on the machine and not moved, the vise is a fast and easy device that keeps setup times to a minimum, according to Joe Cousins, president of Bock Workholding and creator of the system. "What the Bock system adds is the ability to have a vise in one position for job A, then to move it for job B and then to bring it back to the position needed for job A with an accuracy of 0.001 inch.

The system uses three elements to achieve this: a locating plate with a grid-pattern of holes, Dex-Lok double-expanding locating pins; and the vises, which have integral locating holes to match the locator plate.

Today, the company gets more than 14 hours of unattended machining with lot sizes of only 100 to 300 parts per run. "We used to cringe at the thought of having to do a setup," says Mike Jezek. "But with the Bock Workholding system we have fine tuned our workholding and programming to the point where there is very little cringing left."

Related Content

Workholding Fixtures Save Over 4,500 Hours of Labor Annually

All World Machinery Supply designs each fixture to minimize the number of operations, resulting in reduced handling and idle spindle time.

Read MoreCustom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

Read MoreParts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

Read MoreMachining Vektek Hydraulic Swing Clamp Bodies Using Royal Products Collet Fixtures

A study in repeatable and flexible workholding by one OEM for another.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)