Rocklin MobiLase Brings Portability to Laser Marking

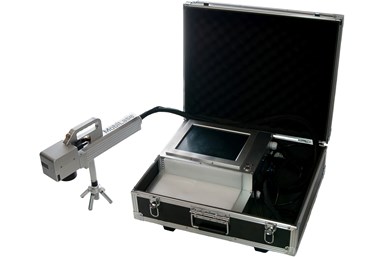

Rocklin Manufacturing’s MobiLase is a portable fiber laser marking solution that customers can transport in a rolling suitcase.

Rocklin Manufacturing’s MobiLase is an all-in-one, portable fiber laser marking unit housed in a 45-lbs rolling suitcase. The company says that moving away from a traditional stationary laser marking unit opens up a world of possibilities for industrial-strength laser marking, and that MobiLase reverse traditional procedures by bringing laser marking directly to the part instead of transporting parts to a laser marking station. Rocklin says this shift eliminates costly downtime and simplifies transportation and workholding when marking large parts.

MobiLase’s 30-W fiber laser and 100 x 100 mm marking window enable the unit to deliver fast and durable laser markings on materials ranging from plastics to steel to precious metals. The handheld applicator includes a trigger to start marking, plus two bracket options to simplify marking various part shapes. These brackets also enable rapid focusing from a consistent, repeatable distance, which is further optimized by the laser pointer simulator.

User-friendly software on the touchscreen PC embedded in the suitcase enables a wide range of easily programmable and potentially intricate markings, including numbers, letters and characters; time and date; barcodes, 2D codes and QR codes; images, logos and symbols.

Rocklin says the MobiLase laser source features up to a 100,000-hour marking lifetime, and the company says it will fully support the device from its Sioux City, Iowa headquarters.

Related Content

-

High RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

-

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

-

Ballbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

.jpg;maxWidth=300;quality=90)