Not being proactive about maintaining spindles is akin to playing Russian roulette with machines, but unfortunately, many manufacturers seem willing to take that chance. Out-of-sight really seems to mean out-of-mind for these critical components, which are often excluded from the routine tasks that manufacturers commonly perform to keep machinery in full working order. Including spindles on that list doesn’t require much extra time or effort and can pay major dividends down the road. After all, when the spindle fails, the machine stops, leaving the user to deal with both the immediate ramifications of a sudden breakdown as well as days, weeks or even months of additional downtime for repair or replacement.

Granted, spindles are sensitive, complex and highly technical components, and many maintenance tasks should be left to professionals with the expertise and resources required for proper diagnostics and service. That said, any manufacturer with rudimentary knowledge of how spindle problems develop can approach production in a way that minimizes risk to these components without ever diving into the assembly. Moreover, vibration monitoring—a key procedure in the arsenal of any professional spindle service provider—can be easier to adopt than some manufacturers may realize. Even smaller shops often quickly recoup their investment in the relatively low-cost equipment available for this task.

First, Do No Harm

While there are many reasons why machine tool spindles can fail, the leading cause is contamination, typically in the form of chips, coolant or condensation finding their way into the assembly. In part, that’s due to the nature of machining. When a machine shuts down, the cooling of the workzone creates a “chimney effect” in which warm, humid air rushes into the spindle. That can increase moisture within the assembly and introduce contaminants. Activating air-purge systems before activating the spindle and for 30 minutes after shutdown can help alleviate this problem. Scheduling downtime for regular cleaning is also critical. Particular focus should be directed toward shaft seals and the spindle’s tool connection, both of which are common entry points for dirt, moisture and chips.

However, contamination often can be blamed not on harsh environments or slow deterioration over time, but human error. Believing more coolant is better, some technicians erroneously point the flood coolant directly into the spindle and bearing assembly, where it can ingress, find its way into the bearings and affect the integrity of the lubrication. Water-based coolants can compound the problem by causing rust to form within the assembly. Coolant is required only

at the point of cut, and if it must be directed toward the bearings, the user should install a deflector unit to interrupt its path.

Manufacturers should also avoid overtightening the belt beyond the manufacturers’ specifications and exceeding recommended feed rates, both of which can overload the bearings. Incidentally, most integral spindles have a thermistor embedded in the motor winding to protect against overloading. Make sure this device is connected to the spindle’s drive or PLC. For block-type spindles, ensure the mounting area is flat within 0.0005 inch. Otherwise, bolting the spindle into place could distort the housing bearing bores. This problem is a common culprit when spindles that run well at a supplier’s facility run poorly on the end user’s shop floor.

Beyond the spindle itself, improperly secured workpieces can cause chatter that contributes to bearing wear, as can unbalanced tools. Forces developed during rotation increase by a squared function, so even a small tool imbalance results in a significant force at high speeds. For the same reason, the pulley should always be balanced with the spindle on belt-driven models. Finally, use longer tools with caution, as cutters that extend too far from the spindle face can change rotor dynamics. The result is increased vibration and reduced spindle life.

Monitoring Vibration

Given that they work with spindles all day long, operators should be trained to watch for signs of trouble. Typical warnings include unusual noises, elevated temperatures and deteriorating part quality. In such cases, vibration analysis can help determine the extent of the problem. If included as part of regular maintenance routines, vibration analysis can even indicate problems developing before the appearance of any obvious warning signs.

The best results come from the same sort of equipment used by spindle service professionals: data collectors with dedicated software that enable users to review spectrums in acceleration, velocity and displacement. The ability to conduct a full analysis of problems with bearings, imbalance, misalignment and more can make such systems a worthwhile investment for shops with many spindles. However, this equipment can cost tens of thousands of dollars and often requires outside training, factors that can make it impractical for small and medium operations with fewer spindles.

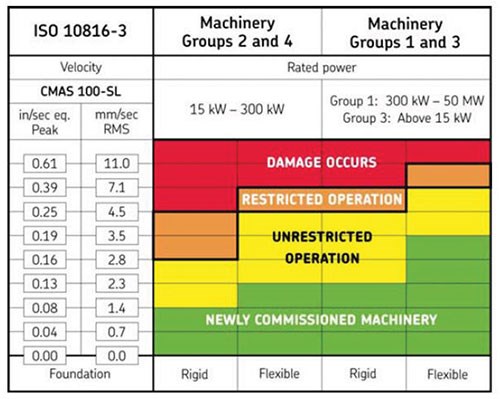

Even if true analysis is out of reach, however, small and medium operations with fewer spindles can still trend spindle performance using another tool: a vibration pen. Costing a few thousand dollars at most, this handheld device enables users to measure acceleration, velocity or both. The device then displays an overall amplitude. Comparing that figure to the ISO 10816-3 severity chart standard can determine the spindle’s condition (normally, these ISO standards and all other instructions for use are furnished with the pen). Performing these measurements regularly and tracking results over time can reveal trends in the spindle’s performance and alert users to a potential problem.

It’s important to note that vibration pen users must take extra care to ensure consistency from test to test. For example, touching the pen to an area of the spindle that’s just a few inches from a previously tested spot can result in dissimilar data that does not represent a true “apples-to-apples” comparison of spindle performance. Marking specific areas of the spindle can alleviate this concern. However, even if the measurement is taken at the same spot, a different amount of pressure or a different angle can skew results. To minimize individual differences, it is best to designate one person with the responsibility for vibration monitoring.

A Word on Repairs

Even the most well-treated spindles will eventually succumb to wear and tear. When that begins to happen, it’s worth remembering that repairs often involve much more than just removing a few bolts and reassembling the spindle. On the contrary, proper repair typically requires expensive equipment and a level of expertise that put the task beyond the capabilities of most manufacturers. Turning to a professional spindle repair service is the best way to ensure the job is done right.

Learn about Gilman Precision.