Taking on Bigger, More Complex Work with Multitasking Machines

Using multitasking machines, Hartman Enterprises was able to increase its part-processing capabilities by taking on more jobs involving larger sized multitasking work.

As many as 380 active jobs circulate around the shop floor at Hartman Enterprises at any given time, so it’s no surprise that Robert Sweet, president and owner, considers multitasking to be critical to the company’s competitiveness and overall success. “In addition to performing multiple part processes in single setups, we often have one machinist running two or even three of our Mazak multitasking machines simultaneously. Essentially, we are putting out the work of four or more conventional machines with only one person,” he says.

From the early 1990s until about 2000, Hartman successfully eliminated secondary operations on multiple machines for many of its parts. However, the shop’s existing multitasking technology lacked the accuracy and rigidity necessary to process more precise, complex parts complete in one setup.

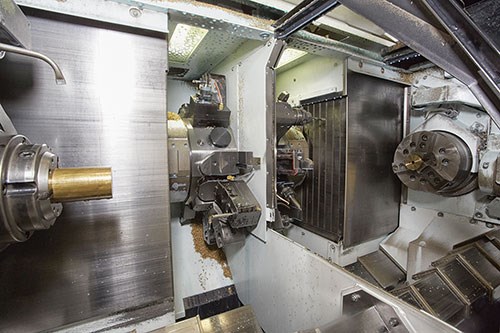

The Oneida, New York shop produces components ranging from industrial pumping systems used in chemical plants and the paper industry, to explosion-proof electrical fittings and fixtures, to freight-train braking systems, among others. On average, the 60-person shop completes 60 jobs per month with lot sizes ranging from one to 2,000 pieces. It also takes on higher-volume blanket orders requiring operations such as turning, milling, forming and welding. To tackle these parts, as well as those that were too big for the shop’s Swiss-type turning machines, Hartman decided to update its multitasking capability by adding seven new high-production multitasking machines from Mazak Corp. (Florence, Kentucky): three Multiplex 6200-II MY machines and four Hyper Quadrex machines (one 150 MSY and three 200 MSY models) featuring twin-spindle/twin-turret configurations.

The standard machining diameter of the Multi-plex measures 10.24 inches, with a maximum swing of 12.6 inches in diameter. The machines enable the shop to accommodate bar work with diameters ranging to 2 inches, shaft work in lengths ranging to 21 inches and chucked workpiece lengths ranging to 7 inches. The Hyper Quadrex machines are equipped with either an 8- or a 10-inch chuck on the main spindle and collet chucks on the second spindles. These machines include enhanced done-in-one capabilities to completely machine parts from slug or bar-fed material in single setups.

The rigidity and accuracy of the Mazak multitasking machines have enabled Hartman to process components made from challenging materials such as stainless steel, Inconel and Nickel 200 with required tolerances ranging from ±0.010 to ±0.005 inch. Most components are produced from round, hex or square-shaped barstock measuring between 1 and 2.5 inches in diameter.

According to Russell Harrington, shop manager, producing tight-tolerance parts with specific surface finish requirements is no longer a struggle using the Multiplex. For instance, the machine’s identical twin spindles and turrets with Y-axis travel are used to machine a brass component for a train braking system that requires holding an ID groove to within ±0.001 inch and an ID bore diameter to ±0.0002 inch. For long-shaft parts, both spindles can hold the part and machine it with synchronized rotation. However, Hartman performs the first operations with the first spindle/turret and then automatically transfers the long-shaft part to the second spindle/turret for the remaining operations. The machine’s twin spindles each offer a 2.4-inch-diameter bore size and deliver 30 hp and maximum speeds of 5,000 rpm. The identical performance enables the shop to complete two parts simultaneously or independently, greatly increasing its part-processing flexibility.

The twin opposing turning spindles as well as twin turrets on the Hyper Quadrex machines also can operate together or separately. A single part can be machined on all surfaces through a coordinated hand-off between spindles, or two different parts can be machined simultaneously. Both spindles have full C-axis CNC control for part positioning and contouring with indexing increments of 0.001 degree.

This option was particularly useful when Hartman needed to process a proprietary part that is simple in appearance, but very complex to machine. The part is held in a chuck in the main spindle and a bell shape is machined during a turning operation. At this point, the part is transferred to the second spindle, which is equipped with a two-jaw chuck for holding the no-longer-round part. In this spindle, the part is bored through, reamed and threaded. Mr. Harrington says the Hyper Quadrex holds all part features concentric with one another to within 0.002 inch. Plus, he says, it consistently generates surface finishes with zero imperfections, as required for the part.

In another application, Hartman has more than doubled its production of pump shaft sleeves with the Hyper Quadrex. Again, the part is more complex than it appeares. Made from stainless steel, Nickel 200, C276 and other exotic materials, the sleeves require a 16 Ra finish on all surfaces. ODs must be held to ±0.005 inch and bores to ±0.0007 inch. Within the bore is a critical undercut that must be held to size within ±0.001 inch, and all part features have to be concentric with one another within 0.0001 inch. The multitasking machine’s rigidity has enabled the company to reduce the number of rough milling passes and take deeper finish passes, which increased production from 32 to 70 complete sleeves per day.

Not only do the Mazak machines improve roughing operations, but they have been beneficial in optimizing drilling processes. Mr. Harrington says he can run drills that he wasn’t able to in the past, and he can run them at higher speeds. “We used to get a lot of chatter in our drilling operations, so we would first drill a pilot hole and then open it up with the finish size drill. Now, we drill to the right size,” he says. “And since we opted for the tool monitor feature on our Mazaks, we can use it to determine drill life and can change out worn drilling tool inserts before they break.”

Both left and right spindles on the Multiplex machines, for instance, are equipped with Mazak’s standard Tool Eye monitoring unit. When the tool tips are brought into contact with the unit, the system automatically registers the tool position information to the machine’s CNC. The system can also be used for tool measurement and breakage inspection.

For lights-out part processing, Hartman targets long-running jobs, such as those for blanket orders. The shop initially sets the machine tool life monitors during the first couple hours a job runs, and steadily advances cutter speeds and feeds until performance is optimized and the exact life span of the tool is noted. This process is carried out during the day shifts, and once exact tool life is determined, the job will then run lights-out. Often, the shop will make two programs for the same part—one that’s more aggressive for the day and another that is more conservative for overnight. The second program may involve a longer cycle time, but the machine is running unattended and producing tight-tolerance work.

“Processing parts exclusively with conventional two- or three-axis lathes would make it impossible for us to compete,” Mr. Sweet says. The company’s part volumes require multitasking and lights-out production. Running lights-out is just a matter of having good tooling and machines that hold tolerance, he says.

Related Content

A New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

Read MorePalmgren Launches Combination Bench Lathe, Mill

The 11" bench engine lathe and gear head mill is able to handle a wide range of turning, milling and drilling operations typically found on much larger machinery.

Read MoreBuilding an Automation Solution From the Ground Up

IMTS 2022 provides visitors the opportunity to meet with product experts to design automation solutions from scratch.

Read MoreHow to Reduce Cycle Times by 70% and More on Your Existing CNCs and Dramatically Improve Tool Life Too

By employing advanced high efficiency milling techniques for the entire machining routine, SolidCAM’s iMachining technology can drastically reduce cycle times while vastly improving tool life compared to traditional milling.

Read MoreRead Next

Obscure CNC Features That Can Help (or Hurt) You

You cannot begin to take advantage of an available feature if you do not know it exists. Conversely, you will not know how to avoid CNC features that may be detrimental to your process.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)