Machining Vektek Hydraulic Swing Clamp Bodies Using Royal Products Collet Fixtures

A study in repeatable and flexible workholding by one OEM for another.

Vektek is known for hydraulic component engineering — specifically its high-pressure hydraulic holding products with automated clamping. Since these hydraulic clamps are required to be leak free with precision fits and excellent surface finishes, Vektek needs to use repeatable and flexible workholding in its own production to machine and change parts quickly.

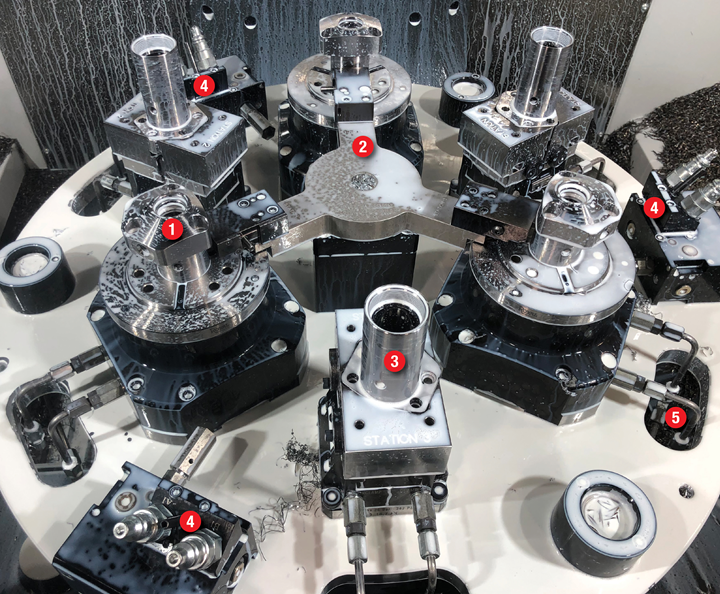

Here’s how the company uses Royal Products Power-Block Collet Fixtures (shown in positions 12:00, 4:00, and 8:00) to produce the set of parts shown here.

- This is Op20 for the swing clamp body. The Power-Block collet chuck clamps on the OD of the cylinder where Vektek machines all the milled features.

- A quick-change locating part that Vektek calls “the spider.” On the ends are spring loaded clocking pins that clock the part when the operator loads the body in the collect chuck prior to clamping in place.

- This is Op30 when Vektek machines the bottom side of the swing clamp body, held in place with a hydraulic centering vise. It is clocked in an orientation, which requires enough tool clearance for an angled hole. The Power-Block jaws for each station are designed to easily change to different swing bodies.

- Vektek’s pallet decoupler. The pallet decoupler has an internal pilot-operated check valve and accumulator that maintains clamp pressure. The operator connects hydraulics lines here, then activates its Advanced Workholding Pump to consistently clamp each station. There are three decouplers so the table can be rotated to each station which allows the operator to easily reach everything.

- Hydraulic lines run under the plate to the corresponding check and vise to help reduce chip trap areas.

Related Content

-

An Additive Manufacturing Machine Shop

Finish machining additively manufactured implants requires different pacing and workflow than cutting parts from stock — different enough for an experienced manufacturer to warrant a dedicated machine shop.

-

Custom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

-

Modern Bar Feeds Bring New Life to Automatic Swiss Lathes

Cam-actuated Swiss lathes are still the fastest way to process many parts. By adding modern bar feeders, this shop has dramatically improved their utilization with the ability to work unattended, even in a lights-out environment.

.png;maxWidth=300;quality=90)