Even after 10 months of use on one machine, FT Precision does not know the full tool life of its EdgeX4 drills from West Ohio Tool. These PCD-edged drills replace the fully carbide mass production drills FT Precision previously used, which were quoted to last for 32,000 holes but rarely reached this milestone. In contrast, the EdgeX4 tooling had surpassed 371,000 holes by the time of my visit in mid-September 2023 — and was still running.

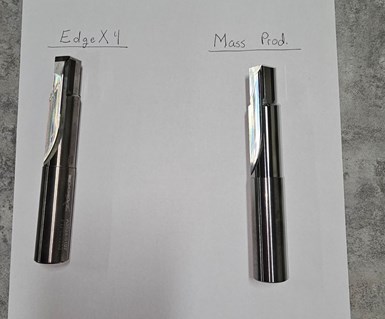

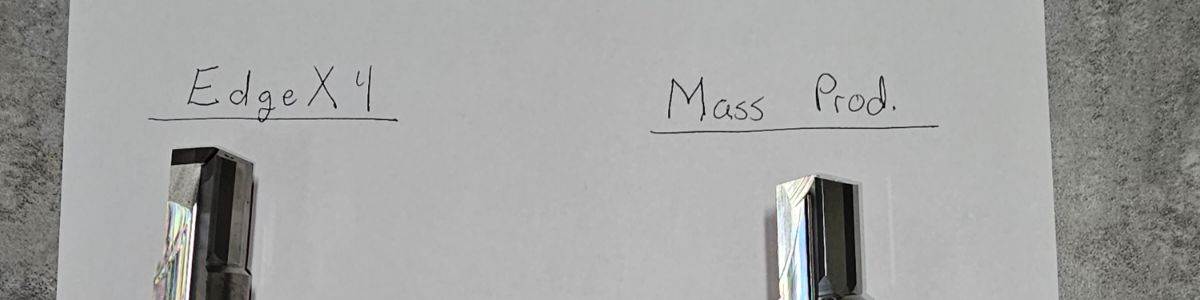

The EdgeX4 drills from West Ohio Tool feature a full PCD edge. While this makes the tools much more expensive than a traditional carbide tool (or even one with PCD corners), the drills have dramatically better tool life. Image courtesy of FT Precision.

The New Edge

FT Precision makes rocker arms for Honda gasoline vehicles, with an ever-shifting split between steel and aluminum parts. The shop first began looking for tooling alternatives after its tooling for aluminum showed abnormally high amounts of rollover, which quickly dulled the tool. With roundness tolerances of 20 microns, dull tooling caused extreme problems, especially for a shop running automated 24 hours a day.

After West Ohio Tool discussed the PCD-edged EdgeX4 drills with tooling staff member Kevin Davis, Davis convinced his manager to try running one of the tools to failure. Despite some initial hesitation from his manager — the tooling is more expensive than traditional carbide tooling, and requires more rigidity for optimal operation — Davis installed the tool. After 10 months, he is still running that trial drill with no performance loss.

High Requirements, High Rewards

This trial drill is not the only EdgeX4 drill FT Precision has installed since realizing the tool life gains they were achieving. The company is also running the tooling on two other machines. One drill, installed not long before my visit, had already reached 69,460 holes — well over double the maximum expected tool life of the carbide tooling. The other had reached 309,800 holes before a spindle crash shattered the tool’s edge the day before my visit.

Davis says the spindle crash had nothing to do with the tool itself, but the tool’s higher cost made him wary to put another on the same machine until the root cause of the crash was solved. The team discovered that the fault for the crash lay with a clamp that failed to close, so they resolved this issue and planned to install a new EdgeX4 tool on the machine shortly after my visit.

Spot Check

To deal with everyday issues — not the rare crashes — FT Precision performs quality checks on inner diameter, roundness and cylindricity at the start of every workday.

The shop’s machining department largely consists of FANUC Robodrills equipped with indexing tables. These machines are grouped by part material type, side and diameter, and each cell shares a robot that picks up workpieces from a carousel and distributes them among the machines.

FT Precision primary uses the EdgeX4 to make rocker arms, a vital part of gasoline internal combustion engines. Both the shop’s aluminum side and its steel side work on versions of the rocker arm, with demand shifting depending on the needs of Honda, its largest customer.

Quality checks across these machines help the shop maintain an otherwise 24-hour production schedule, but changing out tools requires operators to perform the checks over again. While Davis reports that conducting tool changes and quality checks takes only about eight to 10 minutes, this builds up when the operators need to change out tooling every two or three days. Comparing a machine using the carbide mass production tool to the one using FT Precision’s initial EdgeX4 drill, the machine using the EdgeX4 has seen 15-20 extra production hours over the 10 months since the new tool was installed.

Startup Costs vs. Operational Savings

Between these extra hours and the extreme longevity of the tooling, the EdgeX4’s cost per hole is an order of magnitude better than FT Precision’s older carbide tooling. At their best, the carbide tools would achieve unit costs of about 0.035 cents per hole.

The PCD-edged EdgeX4 tooling has a much higher initial cost, but by September 2023 the test tool had reduced costs per hole to a tenth of the former cost — and with the tool still producing holes, the shop could achieve even greater cost reductions.

Now, Davis says he wants to use the EdgeX4 tooling in all of the shop’s aluminum applications, not just roughing. “I’ve been in tooling at FT for 18 years, and its longevity has beat out any tool that we’ve tried. It’s very impressive.”

Related Content

All-Around Mill Improves Productivity and Cost for Valve Job

Adopting a mill with a double-negative rake and pockets compatible with multiple insert geometries enabled Progressive Metal Service to increase feed and lower scrap rates for a valve.

Read MoreToolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.

Read MoreHow to Tackle Tough Angled Pocket Milling With Two Tools

Milling a deep pocket with a tight corner radius comes with unique challenges, but using both a flat bottom drill and a necked-down finishing tool can help.

Read MoreSelecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

Read MoreRead Next

See The Tool's Value Instead Of Its Cost

This company is embracing high-performance tooling on its turning centers. The "sticker shock" is no reason not to do this. In one case, though, the shop found a way to limit the cost of the tool and increase productivity at the same time.

Read MoreSteady Culture, Flexible Plans Enable Custom Tooling Success

By late 2019, West Ohio Tool’s client list only spanned one page. The company overhauled its culture and is now on track for its most successful year ever.

Read MoreWest Ohio Tool Acquires Women-Owned Business Certifications

The company is now a certified Women-Owned Business Enterprise for the state of Ohio, which expands opportunities in obtaining contracts for goods and services, construction, engineering, IT, professional services and other sectors.

Read More

.png;maxWidth=300;quality=90)