Software/Tooling Partnership Promises Easier HSM

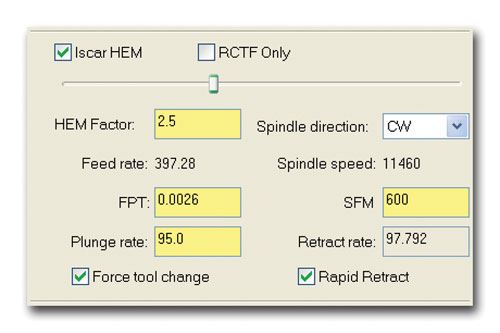

High-efficiency parameters are calculated automatically—partly using a slider that lets the programmer set the level of aggressiveness.

Iscar industry projects specialist Tom Raun says he has often helped shops adopt high speed machining techniques by standing over the programmer’s shoulder during his visit to a shop.

“It works when you do this...,” he might say.

Formerly a tool-and-die programmer himself, he once did exactly the kind of programming work in Mastercam—facing exactly the same kinds of machining and workpiece challenges—as many of his customers today. Unfortunately, though, having support personnel like Mr. Raun give in-person coaching is not a scalable strategy for helping shops get the most from their tooling.

A new partnership between Iscar and Mastercam promises to be much further-reaching.

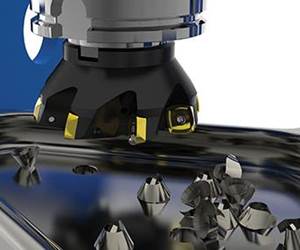

Beginning with the new version X5 of Mastercam, the software’s high speed machining capabilities will now draw upon detailed cutting tool performance data from Iscar. When the software’s “Dynamic Mill” tool paths are used, the programmer can choose from a library of Iscar tools designed for high speed machining, and input just the conventional speed and feed rate information for these tools. From there, the software automatically finds the right parameters for a much more effective machining process—one in which the new parameters might be very different.

“High efficiency machining” is actually the term both companies prefer. That’s because the cutting speed itself is not the main driver of faster metal removal. Rather, the more significant factor is the feed rate increase that becomes possible when the tool path controls tool engagement, and also takes advantage of the radial chip thinning that results from a light radial depth of cut.

Radial chip thinning permits feed rates that can be dramatically higher than what a shop might expect, Mr. Raun says. When the effect of chip thinning is combined with a high spindle speed, a programmed feed rate well over 500 ipm might be possible in a material that had traditionally been milled much more slowly. Various programmers have told him they had avoided such feeds, because they assumed the recommendations citing them must have been in error.

Still other shops have tried to take advantage of chip thinning using feed rate override at the CNC. This is problematic, he says, because the optimal use of chip thinning involves tailoring the speed and feed rate together—something feed rate override can’t do.

The Mastercam software simplifies the use of these seemingly counterintuitive milling parameters. Test data from Iscar’s own extensive cutting trials form the basis of the software’s capability. When high efficiency machining is employed using an Iscar tool, the programmer just selects a radial stepover level, choosing 5, 7 or 10 percent of tool diameter. Then, no other parameter related to higher efficiency has to be known—because the rest of the interface is a slider bar that controls the math involved in getting the parameters right. With this bar, the programmer essentially finds the level of aggressiveness that the shop prefers for its own high-efficiency cutting.

Mastercam sales manager Steve Bertrand explains. He says the programmer starts with standard cutter-use parameters, including feed-per-tooth for the workpiece material. The programmer then varies the slider bar according to his or her own sense of the rigidity of the setup and the rigidity and accuracy of the machine—factors the software cannot anticipate. Based on this input, the software calculates a new speed and feed rate, using formulas aimed at optimizing throughput and tool life. Because spindle speed is not essential to the results, the shop can see benefits on both its high speed and non-high-speed machines.

“The real benefit is that shops now have somewhere to go,” Mr. Bertrand says. The capability helps the large number of shops that do have a machining process able to achieve faster metal removal, if only the right high-efficiency parameters could be found. With the new software that integrates Iscar’s and Mastercam’s insights into an easy interface, meeting this challenge is now just a matter of edging the slider a little further up the scale.

Related Content

10 Tips for Titanium

Simple process considerations can increase your productivity in milling titanium alloys.

Read MoreShoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

Read MoreNew Modular Tool Options for Small Spindle Milling

Tooling options have been limited for small spindle milling applications. Now modular, indexable systems are available that provide broad flexibility to get the right cutter for the job with less inventory and at lower cost.

Read MoreAll-Around Mill Improves Productivity and Cost for Valve Job

Adopting a mill with a double-negative rake and pockets compatible with multiple insert geometries enabled Progressive Metal Service to increase feed and lower scrap rates for a valve.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read MoreObscure CNC Features That Can Help (or Hurt) You

You cannot begin to take advantage of an available feature if you do not know it exists. Conversely, you will not know how to avoid CNC features that may be detrimental to your process.

Read More

.jpg;width=70;height=70;mode=crop)