Mills Hard Powder Metal With CBN Inserts

This shop machines hard, abrasive metal components for plastics-compounding and extrusion machinery. The components are barrels and screws used in machines for mixing and compounding plastic, food and industrial products.

Shear Tool, Inc. machines hard, abrasive metal components for plastics-compounding and extrusion machinery. The components are barrels and screws used in machines for mixing and compounding plastic, food and industrial products. The raw materials are mixed in these machines and extruded into geometric shapes that are converted into salable end products such as snack foods, pharmaceuticals, adhesives, plastics and more.

For three years, Shear Tool engineers found the only machining process that could efficiently cut these grades of Sagittite (ranging in hardness from 53 to 67 HRc) were wire and ram EDM processes. The barrels that the company machines from this material vary in size, with length-to-diameter ratios reaching 15 to 1 on the split barrel and 6 to 1 on closed-barrel parts. Bore sizes range from 25 to 125 mm. The typical wire and ram EDM processing time for a single barrel, depending on its size, was 80 to 100 hours. The smaller barrels, which are machined on the wire EDM system, required secondary finish diamond grinding to remove line marks left by the machining process.

Steve Dill, CNC group leader at Shear Tool, aggressively investigated different cutting tools in order to shift the machining of the barrel parts to the company's vertical and horizontal machining centers. "We wanted a more cost-efficient machining process, especially for the boring operation on these parts," he says. To be a successful solution, the cutting inserts had to support Mr. Dill's goal of performing helical milling.

Mr. Dill called on the expertise and support of cutting tool suppliers from around the world. "We tried every grade of carbide we came across. We tried several other types of tools with CBN inserts mounted in them. You name it, we tried it." Each supplier would bring in the cutting tools it believed would tackle the Sagittite material. According to Mr. Dill, the testing did not last too long. "It usually was a matter of minutes before the cutting tool would just burn up. The best carbide tool available made acceptable chips for three or four revolutions. After that, the chips would turn into dust. Shear Tool continued to use these tools for a maximum distance of 5 inches. Most tools would burn up before that distance."

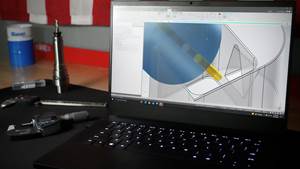

Personnel from Shear Tool sat down with their product specialists. The engineers discussed the material and its properties, their problems, as well as the company's objectives. From that discussion, they decided to try a Sandvik Coromant (Fair Lawn, New Jersey) CoroMill 200 cutter fitted with a new insert—a carbide substrate to which a CBN insert is brazed. This tool offers high wear and heat resistance to support high material removal rates and the machining of abrasive materials.

The first test involved an 80-mm diameter face-milling cutter fitted with five CB50 inserts cutting a scrapped production part composed of the softer grade of Sagittite. Helical milling parameters for this test were 200 sfm, with a feed of 0.007 inch per edge. "Our side cuts were 0.040 inch, and our depth of cut was 0.080 inch per revolution. So, for every circular revolution, we would drop the Z-axis down 0.080 inch."

Mr. Dill and the Sandvik engineers were very pleased with the test. While generating large, shiny chips, the tool successfully removed a total length of 11,663 inches of material. "That is 2,300 times more than the carbide, which could only cut 5 inches before burning up," recalls Mr. Dill.

Halfway through the test, Mr. Dill increased the bore depth of cut to 0.050 inch.

The tool continued to cut without any difficulty. After removing enough metal to produce a single part, inspection of the tool revealed no wear or damage to the inserts.

Shear Tool quickly ordered additional face-milling cutters in 40- and 60-mm diameters. Along with the 80-mm diameter cutter, these sizes would accommodate the range of workpieces Shear Tool needed. "This insert promises us a considerable amount of savings on this project," says Mr. Dill. "We can mill the parts in 20 to 25 hours, which is 25 percent of the time it took to EDM them. It also means we no longer have to machine the carbide electrodes to cut these parts."

According to Mr. Dill, the success of the CBN insert, along with the helical milling technique, dramatically changed how the company will process parts now. "This tool has opened up a lot of new avenues for us," he explains. "Currently, the milling operation is a roughing operation, with the parts receiving surface grinding afterwards. After some more testing, we think we will be able to double our surface speed and even eliminate the grinding operation."

Mr. Dill already has a number of new application ideas in mind for this insert and cannot wait to test them all. "Only a few months ago we were at a point where we didn't think we would ever be able to machine this material efficiently. Now we can cut even the harder grades of this material. What's more, the insert promises savings in time and tool life on milling jobs we were already doing successfully."

Related Content

New Modular Tool Options for Small Spindle Milling

Tooling options have been limited for small spindle milling applications. Now modular, indexable systems are available that provide broad flexibility to get the right cutter for the job with less inventory and at lower cost.

Read MoreQuick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreHow to Tackle Tough Angled Pocket Milling With Two Tools

Milling a deep pocket with a tight corner radius comes with unique challenges, but using both a flat bottom drill and a necked-down finishing tool can help.

Read MoreBuying a Lathe: The Basics

Lathes represent some of the oldest machining technology, but it’s still helpful to remember the basics when considering the purchase of a new turning machine.

Read MoreRead Next

Obscure CNC Features That Can Help (or Hurt) You

You cannot begin to take advantage of an available feature if you do not know it exists. Conversely, you will not know how to avoid CNC features that may be detrimental to your process.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)