Arlie Branham remembers a time when rebuilding a particularly complex solid model in preparation for CAM programming might have taken as long as three days. Now, the same task might take only half the time, depending on the model. Likewise, design and programming changes don’t create the same headaches they once did. Setups are easier, and clearance issues and other potential problems are now caught and remedied before machining begins. Metal removal rates and cycle times have improved, and machines and cutting tools alike are lasting longer.

Mr. Branham is a programmer at Tomak Precision, a job shop in Lebanon, Ohio that specializes in close-tolerance work in hardened materials. He attributes the gains outlined above to the shop’s implementation of CAMWorks, a solids-based CAM system from Geometric Americas (Scottsdale, Arizona). Equipped with an array of tools that simplify and automate even complex programming tasks, the software helps the shop move from customer drawings to machining programs accurately and efficiently, he says. Meanwhile, its seamless integration with VoluMill, a toolpath engine developed by Celeritive Technologies (Cave Creek, Arizona), ensures tool paths take full advantage of the capabilities of the shop’s equipment.

Tomak Precision’s 20,000 square feet of manufacturing space is home to equipment for turning, milling, grinding, EDM, inspection and more. Work ranges from prototype jobs to short lots to full production runs. To meet the requirements of customers in the aerospace, medical, machine tool and other industries, the company prioritizes training and continually evaluates new technology, says A.J. Schaeper Jr., general manager. That includes software, and Mr. Schaeper says CAMWorks has helped maintain profitability amid the economic difficulties of the past few years.

One of the system’s most significant time-saving features is associativity between CAD and CAM functions, Mr. Schaeper says. This enables the software to identify and recalculate tool paths automatically based on changes to the part model. For example, when the depth of a pocket changes in the model, the tool path updates automatically. As a result, it takes less effort to accommodate design and programming changes.

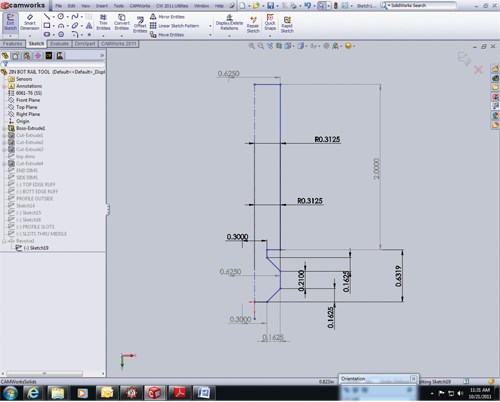

Seamless integration with SolidWorks is also important because many of the company’s customers use the feature-based CAD system, Mr. Schaeper says. The ability to import solid models directly into CAMWorks and work with them from within the CAM environment is a significant time-saver. Mr. Branham agrees. In fact, he estimates that specific time savings range from 10 to 50 percent, depending on the complexity of the model. “In the past, rebuilding a solid model would take anywhere from an hour to three days,” he explains. “Importing the model into CAMWorks and working directly from it so that we are not reinventing the wheel is faster and more efficient.”

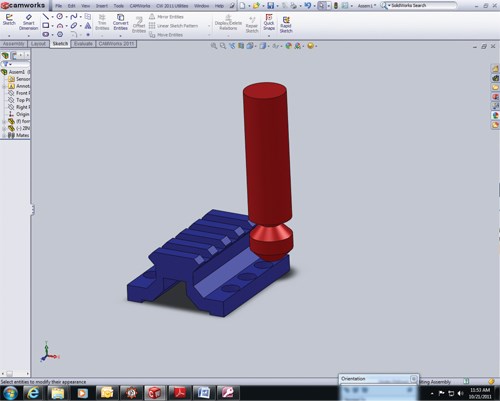

Other capabilities come into play after machining programs are finalized. For example, the software provides an accurate, realistic representation of the machining environment, including all machine components, workpieces, fixtures and so on, Mr. Branham says. This helps operators on the shop floor save time during setups.

Likewise, the software’s simulation capabilities ensure programs are accurate before machining cycles begin. “You can verify everything right on the screen,” Mr. Branham notes. “You can see quickly if your tool doesn’t have enough flute length, if the corner radius on your tool is too big or too small. The ability to do things like that without ever putting tool to metal is a major money saver.”

The software also helps select the right tool for a given job. If the right tool isn’t available in the CAMWorks tool library, the programmer can draw that tool and use it in simulation. “This has removed a lot of the guesswork from tool selection, which is important for our business because a lot of the parts we do are very complex and place a variety of demands on the tooling,” Mr. Branham says.

Generating machining programs from imported solid models more quickly and accurately has helped the shop win jobs, Mr. Branham says. And as of this year, CAMWorks has provided additional benefits. In large part, that’s thanks to YouTube, which Mr. Branham calls “one of the best tools in my toolbox.” He says he often peruses the free video site to stay up-to-date on the latest technologies. “I just type in a generic heading, like ‘milling aluminum,’ and see what comes up.”

One video that caught his eye depicted a stainless steel roughing operation with an exceptionally high metal removal rate. The software that supposedly made this possible

was called VoluMill. Impressed, he sought out more VoluMill videos. “At first, I thought they were stretching the truth,” he says. “I looked into it more and realized this was for

real. This was a game-changer.”

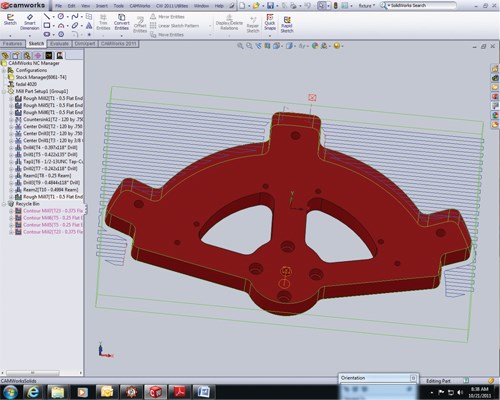

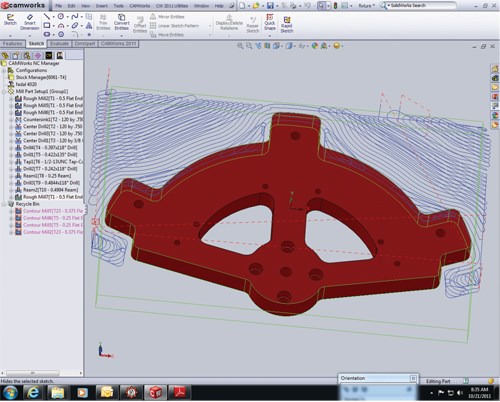

VoluMill generates tool paths designed to maintain a constant load on the cutting tool and machine tool spindle. According developer Celeritive Technologies, this enables cutting more aggressively while extending tool and machine life. The toolpath engine is said to be effective for virtually any material and virtually any shape that can be rough-milled in a two- or three-axis CAM system.

The software works by controlling the rate of material removal. Unlike tool paths that are plotted according to the geometry of the feature being machined, VoluMill paths are designed to avoid abrupt changes in direction, such as those that occur in corners. Along with this smooth, continuous motion, the software maintains a constant, user-defined stepover and dynamically adjusts feeds, speeds and cutting depths according to tool engagement with the material. According to the developer, the resulting path avoids load spikes and ensures that users get the most from the capabilities of their machines and cutting tools.

Mr. Branham and Mr. Schaeper’s timing was fortuitous—before they could buy VoluMill, they learned that it would be fully integrated within the 2011 version of CAMWorks for 2.5- and 3-axis roughing applications. Tomak became one of the first shops to take advantage of that option when it took delivery of the new version in March 2011.

Mr. Branham says using the toolpath engine is as simple as selecting it from a drop-down menu in CAMWorks’ roughing tab. Its greatest benefit is toolpath efficiency. “There is no wasted motion,” he notes. “For example, when you calculate an internal corner, there is a whole lot of math involved. CAMWorks with VoluMill does most of that math for you. That saves an average of 50 percent on machining time for these features.”

As another example, he cites a hypothetical job that involves removing a large amount of material from a part’s exterior. Another system, he says, might require creating numerous tool paths to “step in” the tool and avoid overload. VoluMill, in contrast, maintains a constant radial load on the tool and never deviates. “If you tell it 20-thousandths stepover, it will do that every time,” he adds.

In all, VoluMill has increased material removal rates enough to achieve cycle time reductions ranging to 80 percent in some cases. The shop reports that tool life has also improved, sometimes by as much as 500 percent. Coupling these benefits with time-saving features of CAMWorks has helped the shop improve efficiency and attract new work, including parts it wouldn’t otherwise have been able to make, Mr. Schaeper says.

.png;maxWidth=300;quality=90)