Integrated CAM Software Automates Data Transition From Engineering to Production

By switching to CAMWorks software, Decimal Engineering was able to boost its throughput and quality while saving time and money.

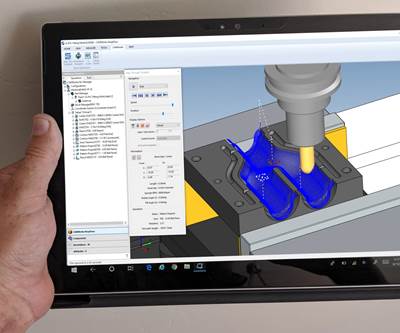

CAMWorks ShopFloor provides a digital manufacturing solution by providing 3D models with MBD and PMI data, along with CNC programming information to the shop floor in a single, compact digital format.

To remain competitive, Florida-based Decimal Engineering Inc. needed to shorten production lead times, minimize scrap/rework and maximize machine uptime. In the midst of this, the company was spending considerable time iterating back and forth between engineering and manufacturing to rework parts before cutting them, often wasting time and scrapping material if something was missed. Adding to the challenge was the increasing complexity of its customers’ parts.

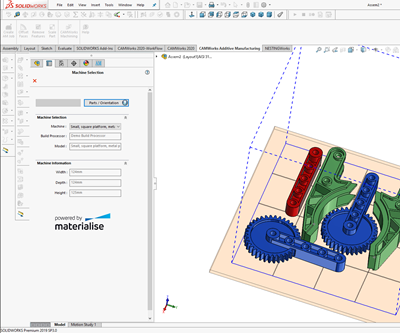

In 2014, Decimal decided to address these issues by replacing its CAM software with CAMWorks machining software, including the CAMWorks VoluMill high-speed machining module. CAMWorks’ full integration with Solidworks CAD software, as well as its robust feature recognition capabilities and extensive knowledge database were key features that helped Decimal reach this decision. In 2020, the company added the CAMWorks ShopFloor application to support remote programming, bring all machining/programming information for a job onto a single dashboard, and provide shopfloor personnel with access to model data for measurement, simulation and interrogation purposes.

“We needed an integrated solution to automate the process of transitioning from engineering to production,” says Decimal President Alan Garey. “Because our previous solution was not integrated, those changes frequently didn’t make it back to engineering. This sometimes led to duplicate work and time wasted.”

According to Mr. Garey, the integrated system can handle the design changes needed to support manufacturability while capturing those changes in the Solidworks single modeling environment. It has also eliminated the company’s reliance on paper drawings, which have been replaced with on-screen 3D PDFs.

Shortened Setup Time

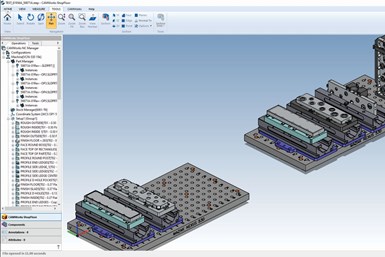

Since implementing CAMWorks ShopFloor software, Decimal now has remote programming capabilities — G code and all machining information are received in a single package. Decimal has also acquired productivity-enhancing tools for obtaining information or interrogating the model of a part to be machined from the shop floor and simulating the machining process. CAMWorks ShopFloor capabilities include measurement, cross-sectioning, machining simulation, and the ability to simulate the tool, toolholder and the tool’s stick-out length. The addition of these capabilities has resulted in a 50% reduction in machine setup time.

“I really pushed for the CAMWorks ShopFloor implementation because it enables us to work smarter and faster,” says Jason St. Pierre, machine shop supervisor.

According to machine shop supervisor Jason St. Pierre, CAMWorks ShopFloor is an all-in-one machining package because all the information needed to run a job is available on his computer and on the shopfloor monitors used by setup personnel. This information includes the program, the tool list, the setup sheets, images of the setup, 3D simulation of the machining process, the engineering drawing and a read-only 3D model of the part to be machined.

“As its name implies, CAMWorks ShopFloor is super beneficial on the shop floor,” Mr. St. Pierre says. “If a dimension is missing from a print, we can pull out any feature and measure it. We can section-cut a model to gain important missing dimension information, such as on a deep blind hole. We can even visually simulate the entire machining program in all three dimensions, watching on screen to see how the tool moves and removes material, which helps us avoid costly collisions and make important tool corrections. CAMWorks ShopFloor even sounds an alarm if we attempt to machine the wrong revision of a part.”

Greater Automation and Accuracy

Since implementing CAMWorks machining software, Decimal has achieved greater automation and increased accuracy, resulting in fewer errors and less machine downtime. In fact, Mr. Garey says the move to CAMWorks has led to a 30% increase in machine uptime.

Throughout its history, Decimal Engineering has grown steadily, expanding into a full-service manufacturing services provider that operates in a new state-of-the-art production facility.

“Whenever we had to iterate a job using our previous software, we experienced downtime, and we gradually lost confidence in the solution,” says senior engineer Gary Saltzer. “With CAMWorks, it’s much easier to make a design change and have it automatically reflected in the manufacturing model. The software is more efficient. Something that took 20 mouse clicks in our previous CAM software takes about five mouse clicks with CAMWorks. Because CAMWorks uses Solidworks as its modeling front end, all changes are captured and reflected in our engineering model. None of the modifications are lost, which leads to fewer mistakes.”

Mr. Saltzer says that CAMWorks gives engineering more control of the process. “The difference in how we work now with CAMWorks compared to before we implemented the solution is night and day. With CAMWorks, we can post a G-code program, and our machinists can just run it instead of coming back to us and iterating on it over and over.”

Eliminating Paper, Minimizing Scrap and Rework

In addition, Decimal has been able to implement a completely paperless documentation system with all drawings, setup sheets, shop prints, tool lists, models and machining processes digitally represented via monitors on the shop floor. The CAMWorks implementation is not only helping Decimal to eliminate more than $25,000 in annual costs related to paper, plotters and printers, but it’s also allowing the company to cut scrap/rework costs in half, even though the company is handling increasingly complex and sophisticated parts.

“With the automation that we’ve achieved with CAMWorks, we’re able to handle complex parts without extending delivery times while simultaneously reducing scrap and rework,” Mr. St. Pierre says. “Everything related to a job is now accessible from the shop floor. They can pull up the information that they need and even section the model if they need additional details instead of having to decipher a paper drawing, ask engineering or go back to the customer. Ultimately, the move to CAMWorks has helped us to shorten lead times while improving quality and surface finishes at the same time.”

Related Content

How to Grow the Business with Real-Time Job Status Data

ERP systems that focus on making data more accessible can improve communication within a shop, reducing wasteful errors and improving capacity.

Read MoreTips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

Read MoreWhen Handing Down the Family Machine Shop is as Complex as a Swiss-Turned Part

The transition into Swiss-type machining at Deking Screw Products required more than just a shift in production operations. It required a new mindset and a new way of running the family-owned business. Hardest of all, it required that one generation let go, and allow a new one to step in.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreRead Next

CAMWorks ShopFloor Unifies CAD/CAM Part Data to Avoid Errors

CAMWorks ShopFloor provides tools for companies to adopt so-called smart manufacturing and Industry 4.0 initiatives by moving beyond 2D drawings or static digital files.

Read MoreCAMWorks 2020 Provides SolidWorks Support

HCL Technologies has developed CAMWorks 2020 with enhancements designed to assist machine shops in advancing their Smart Manufacturing practices.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)