How I Made It: James Marzilli, Founder/President, Marzilli Machine

James Marzilli founded Marzilli Machine before the age of 30 on a dare from his wife Lee Anne, who now serves as CEO. As president, James has led the company to success by constantly refining his shop’s processes and seeking to learn.

It's important for me to be proactive about learning and to not be an egomaniac about things and try not to be a know-it-all. I try to be a learn-it-all. So I go to a lot of the tools shows. I get involved. I learn things.

I want to be able to talk to the people that work for me and know they’ll understand what I'm talking about. And so I take the entire shop to Eastec every other year because how do you explain things like a B-axis lathe or a scanning head for a CMM or an optical comparator? How do you explain things like that without having one in front of somebody?

I took everything we learned from 5S and lean and boiled it down to two sentences. The most important one was: You have got to be able to find what you're looking for in 10 seconds or less. If you can't find what you're looking for in 10 seconds or less, your system is broken and you need to take another look at it.

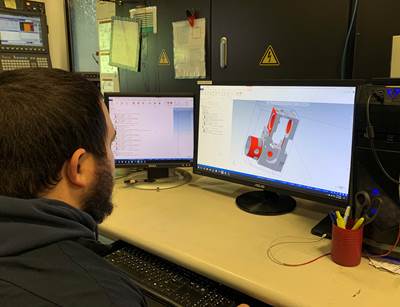

James Marzilli is the owner and president of Marzilli Machine, a job shop in southeastern Massachusetts. Over the past 13 years, the shop has grown exponentially and secured clients in the high-tolerance medical, aerospace and defense industries. Photo courtesy of Marzilli Machine.

The number one rule about a system is that you can't make a system that has someone's name in it. We used to write all the rules and say “When you get to this point, go ask James what to do.” That's a bad system, because if I go on vacation, that system grinds to a halt. So if that was rule number one, then rule number two is, whatever system you're designing, you have to design it so it will scale. Because we're going to triple in size, and we don't want to keep doing it over.

That's the thing about being a young guy. I'm never thinking about what were the last 20 years. I'm always concerned with what are the next 20 years going to look like.

I actually find that people who play musical instruments make good machinists. The creative types who can connect the dots with things. If I'm going to take on an apprentice, one of the things I ask is if they play a musical instrument or what kind of hobbies do they have. I'm looking for people who like to play with Legos and paint pictures and draw and that kind of stuff. Those people tend to make very good machinists.

There's a saying out there in sales: “Sales sells the first one, service sells the rest.”

I want to change my company to become a customer service-orientated manufacturing company because I do believe that is the only space left that you can really compete. With digitalization and automation, we're all going to start playing on the same playing field very soon because we're all going to be working from the similar stuff.

Read Next

AMT Announces IMTS 2024 Floor Plan

IMTS 2024 will include demonstrations featuring robots, cobots, vision systems, as well as other manufacturing processes such as additive manufacturing, CNC machining, metrology and part handling.

Read MoreDigitalized Job Shop Scales Up

New software sparks new thinking about meeting quality certification requirements without stifling growth.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)