Loading the player ...

When Smooth TCP is activated (video on the right), the cutting tool moves noticeably faster. Movement of the workpiece in the rotary axes is also smoother--the jerkiness noticeable in the video on the left has been virtually eliminated.

For the spectator, one of the joys of watching a sporting event is to witness the sheer grace of premier athletes in action. The power, economy and precision of their bodily motions is gratifying to behold—especially when it is part of a great play or spectacular move that wins the game or bests the competition.

Watching a CNC machining center performing high speed milling in simultaneous five axes can be an experience of similar interest and wonder. The coordinated movements of powerful mechanical axes have a certain grace, too, as the cutting tool races across the flowing lines of an intricate workpiece contour.

However, smooth, graceful moves of a cutting tool in five-axis machining mean more than whatever thrills they offer the spectator. They are usually a good indicator that the cutting tool will leave a smooth surface with minimal dwell marks. Five-axis machining is one of the processes that a major athletic footwear company relies on at its in-house facility for machining plastic injection molds. MMS visited this shop late last summer to see how it does it. These molds are used to produce prototypes for design evaluation and testing. Because these prototypes are a critical part of the company’s design process, the ability of this shop to produce these molds quickly and accurately is essential. In fact, producing molds and generating prototypes in 24 hours (or even overnight) is typically a requirement.

This is a main reason why shop managers there were so interested in a demo of a new function for high-end CNCs being introduced by FANUC at IMTS 2008. This function, called Smooth Tool Center Point (TCP) control, automatically adjusts servo commands to avoid unwanted, jerky moves when the cutting tool is programmed to maintain the same orientation to the workpiece surface during five-axis machining. The result of this adjustment is smoother cutting action with less chatter and fewer tool marks on the surface. With Smooth TCP, the cutting tool also lasts longer, and there is less wear and tear on the machine tool.

At the time, the managers had been visiting the Mori Seiki booth across the aisle at the show. The footwear mold shop had acquired its first five-axis vertical machining center, an NMV5000DCG, from this builder in mid-2007. This machine had been selected after a lengthy qualification process that involved a challenging test part that combined the shop’s most difficult machining requirements.

In addition to outperforming other machines in the running, this VMC proved the value of five-axis capability for this shop’s operations after it was in place. Based on these experiences, the shop decided to acquire a second machine like the first.

One of the sales engineers at Mori Seiki suggested investigating the Smooth TCP feature. At the nearby FANUC booth, a video of five-axis machining with and without Smooth TCP was the clincher.

A few months later, the shop placed an order for the additional NMV5000 DCG—and stipulated that it had to have the Smooth TCP onboard. It was clear that additional five-axis machining capacity with advanced control capability would be a valuable asset. It could help the shop, and the company it served, win the race to market with new products.

A Team Effort

The market for athletic footwear is extremely competitive. Market leaders devote huge resources to research and development in an effort to be the first to introduce innovations and new styles.It is no surprise, then, that market leaders maintain some of the most well-equipped and up-to-date machining and molding operations. The faster and better they can produce molded parts, the faster and better designers can create market-winning products.

The shop that MMS visited houses 10 machine tools and employs five master toolmakers. The two five-axis VMCs are the newest machine tools in the shop. Although the machines were installed about a year apart, they are virtually identical and stand side by side. Both are equipped with FANUC 30i series CNC systems.

The original NMV5000DCG was one of the first of this model to be installed in North America, and the newer one was the first to have Smooth TCP. For this shop, being an early adopter means sharing a steep learning curve with the builder, the CNC supplier and the local distributor (in this case, the Wilsonville, Oregon office of Ellison Technologies). Ellison had been instrumental in the installation of the first five-axis machine a year earlier. For example, Stephen Witmer (an Ellison sales engineer) arranged to have the qualifying test cut performed at the builder’s factory in Japan.

According to the shop manager, Smooth TCP was so new when the second machine arrived that both the machine tool builder and the CNC developer had to work closely with the shop during installation. All of the parties were trying to figure out what was the best implementation. Randy Murphy, an Ellison applications engineer, coordinated the effort to make this new technology successful.

John Goes, VP of operations at this Ellison office, explains that this collaborative effort was essential because implementing Smooth TCP required “tuning” the machine tool’s servo system to the settings that best matched the shop’s requirements and expectations. “There’s only so much that can be done at the factory. It really takes a strong presence at the user’s facility to get the exact calibration. Teamwork is as important in this effort as it is on the sports field,” he says.

Mr. Witmer notes that this particular shop operates in an especially demanding atmosphere. The shop takes on between 700 and 1,000 projects a year. A typical project, such as an outer sole design, may require as many as eight molds. An increasing number of these projects call for five-axis machining because it is either the most efficient way or the only way to produce certain features, such as undercuts.

However, efficient five-axis machining is only one part of the total, streamlined mold production process in place at this shop. It has adopted a number of principles to make it lean, efficient and automated. For example, the shop stocks prefinished mold bases in sizes that are optimal for 98 percent of the mold work it undertakes. Likewise, CNC programmers have developed macro routines for all the mold base prep work to automate that part of the programming process.

With a workflow already established for fast turnaround, improvements such as Smooth TCP go straight to the bottom line, so to speak. “They can see the payoff in time savings immediately,” Mr. Witmer says. Shortly after Smooth TCP was installed on the new machine, it was then installed on the original machine.

Steady but Smooth

Technically, Smooth TCP is an enhancement to operating a five-axis machine in the tool center point control mode. FANUC provides this explanation: On a five-axis machine equipped with two rotary axes, TCP performs tool length compensation constantly, even in the middle of a block, and it exerts control so that the tool center point moves along the specified programmed path. With TCP, the programmed tool center point moves on a commanded path even though the tool posture may vary.

In some cases, a machining program may include unevenness in the tool posture between blocks. In such a case, the position of the control point from the position of tool center point varies in every block; hence, many accelerations/decelerations occur, and the control point cannot move smoothly. As a result, processing time increases and a machined surface is degraded.

Smooth TCP is a feature that compensates the positions of the rotational axes in a way that decreases the unevenness in the tool posture. This feature causes the rotational axes to move smoothly in a machining program that is utilizing TCP. Applying Smooth TCP leads to decreased processing time and a finer machined surface.

Mr. Witmer points out that the difference between watching a five-axis operation with Smooth TCP and without can be dramatic. “Although the relative motion at the tip of the cutter is similar in either mode, you can see a real change in how the spindle end of the tool behaves as it encounters certain geometry. With Smooth TCP, that end of the tool makes fewer swings and gyrations as it follows complex contours.”

Of course, five-axis machining is not a spectator sport, although racing to complete molds in 24 hours does mean that this mold shop has to keep its eye on the game clock. For this reason, the time savings that tool center point control and the Smooth TCP enhancement bring to five-axis machining are significant. The shop estimates that tool center point control may reduce machining time by as much as 50 percent and, where it is appropriate, Smooth TCP can reduce time another 25 percent. (According to tests conducted by FANUC, time savings from Smooth TCP can range from 10 percent in typical cases to 44 percent in extreme cases.)

Smooth TCP saves time in two ways. For one, it avoids excessive, radical changes in the axis positions dictated by the orientation of the cutting tool. These motions can slow down the execution of the toolpath commands and leave dwell marks on the workpiece surface. Another result of smoother tool motions is less vibration at the tip of the tool. This improves surface smoothness, especially in finishing cuts. The mold can come off the machine with surfaces that need little or no handwork.

Mr. Witmer reports that only surfaces requiring a mirror finish, such as those for footwear molds or cleats, are routinely turned over for hand polishing. “This is the second big time savings pay-off,” he says. Completing molds on the machine means that running in the unattended mode has the maximum impact on overall productivity. The shop operates around the clock, but only one shift a day requires the toolmakers to be present attending the machines.

However, Smooth TCP is not activated for every five-axis operation. This shop’s experience shows that it can compromise accuracy on some geometry, such as certain steep-walled cavities. “Whether to use Smooth TCP depends on a number of factors, including the tolerance band the user sets as a parameter,” Mr. Witmer says. A 3-degree setting provides the fastest, smoothest machining, whereas a 0.5-degree setting yields a slower but more accurate cut.

Underlying Stability

At Ellison Technologies, Mr. Goes points out that Smooth TCP is an enabling technology for five-axis users, but in terms of the underlying machining capability, it is really an enhancement to a machine structure already well-suited for the application. Both roughing and finishing operations benefit. “The design of the NMV5000DCG provides an inherently stable platform for five-axis machining,” he says.

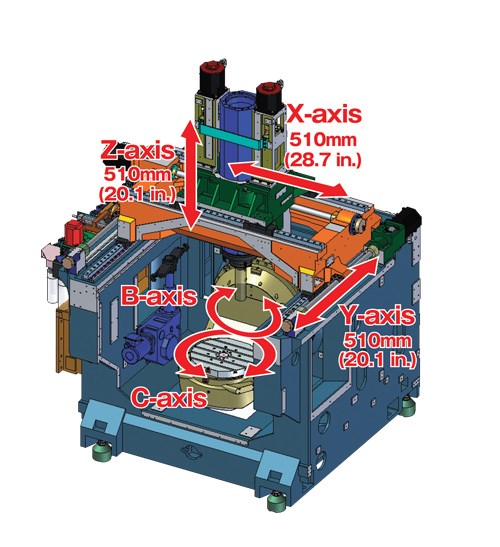

For example, this model uses a cantilever rotary table configuration rather than a trunnion design. Tilting and swinging the workpiece enables the cutting tool to reach the bottoms of deep pockets, such as those that form cleats on a shoe undersole, with fewer clearance issues. More importantly, the design allows integral, direct-drive motors in the B and C rotary axes. The integral motors are large enough to provide adequate speed and torque to complement the capabilities of the other axes, yet the mass of these rotary axes is manageable. The lack of backlash also improves rigidity, Mr. Goes says.

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)