CAM System Smooths Shop’s Transition to Ventilator Part Production

Pindel Global Precision’s CEO used his Navy SEAL experience to help his shop navigate the switch from one CAM system to another while manufacturing new ventilator parts in the middle of a pandemic.

Share

Read Next

Founded in Milwaukee, Wisconsin in 1947, Pindel Global Precision has endured through some of the country’s toughest times — wars, economic recessions, and, presently, a pandemic. The appearance of unlikely heroes such as Pindel is one silver lining of difficult times.

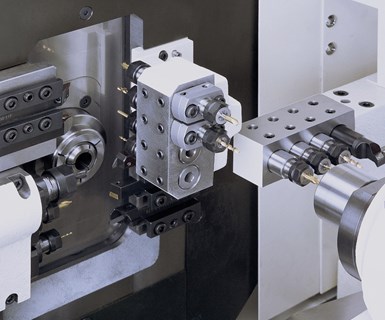

Typically, Pindel uses a range of equipment like this Tsugami to manufacture parts for the industrial control and automation industries. When the coronavirus pandemic increased the need for ventilators, CEO Bill Berrien offered his company’s services, producing ventilator parts at cost. Photo: DP Technology

Pindel, an ISO9001:2015-certified contract manufacturer of precision-machined parts for global customers, typically serves the industrial control and automation industries. But when COVID-19 hit, CEO Bill Berrien saw an opportunity to help. “We put our name out there as a candidate willing to make ventilator parts at cost,” Mr. Berrien says. “There was a national, humanitarian urgency to meet the need. We had to raise our hands.”

At the same time, Pindel was in the middle of another big change — switching its CAM system to Esprit. The shop found that its previous CAM program didn’t have the support it needed, especially when it came to CNC Swiss and complex turned parts. Additionally, the team was frustrated by the frequent editing the previous system’s programs required. According to Mr. Berrien, Pindel’s decision to go with Esprit was based on the company’s emphasis on continuous innovation. “Esprit’s regular feature launches, AI capabilities and reputation for creating great, edit-free NC code make it a better choice to help the team work together and work quickly,” he says.

Lifelong Lessons

The importance of teamwork is something Mr. Berrien learned after college while serving the country for nine years as a Navy SEAL officer. “They say that once you leave the SEALs, you spend your entire life trying to recreate the experience,” he says. After the military, he earned a graduate degree from Harvard Business School before heading to the Midwest to work for GE and ultimately Pindel, which he acquired in 2012.

“I believe that manufacturing can replicate that SEAL experience,” Mr.

While Pindel was pivoting to ventilator part production, the company was going through another major change. After much frustration with the lack of support and frequent program editing its previous CAM system required, the shop decided to switch to Esprit. Photo: Pindel Global Precision

Berrien says. “You’ve got a small, highly cohesive, highly trained team trying to do outsized things.” Responding to the manufacturing needs of a global healthcare crisis only highlights the possibilities of this model. “The manufacturing ecosystem we have in this country, and particularly Wisconsin and the upper Midwest in general, can make us the world’s factory floor,” he says. “But it has to be enabled by automation and AI. [At Pindel] one of our key mottos is, ‘Work smarter, not harder.’ If there’s a tool out there that lets the person do more, let’s jump on it.” COVID-19 was Pindel’s watershed moment, and Esprit helped smooth the transition.

Stepping Up

According to Mr. Berrien, the Pindel team, particularly regional sales manager Mark Quartana and applications engineer Derek Peters, stepped up to meet the challenges of both switching CAM systems and producing ventilator parts. “We asked Derek to program the part on a Friday. Our team here in Wisconsin worked through the weekend, and Derek kept in touch with us. By the following Monday, we were cutting chips on test material — on all five different part numbers,” Mr. Berrien says. “By Tuesday we were making parts, and by Wednesday we were anodizing them.” He adds that the key to successfully navigating this transition was trust — both in Esprit and his team.

Mr. Berrien sees many parallels between his experience as a Navy SEAL officer and manufacturing, especially when responding to a situation like a pandemic. “You’ve got a small, highly cohesive, highly trained team trying to do outsized things,” he explains. Photo: Pindel Global Precision

“It’s very similar to what I saw in the Special Operations community. You don’t have a single leader giving direction on the little points,” Mr. Berrien continues. “Instead, you build a team, give them a goal and you let them go without meddling. This leadership approach empowers the team to problem solve as they need to.”

Today, as Pindel continues to manufacture ventilator parts at full speed while simultaneously pursuing AS9100D certification, Mr. Berrien looks toward the future. “I believe that on the other side of this crisis, there is going to be a realization that the legacy mindset around supply chains is no longer applicable. The default setting of OEM sourcing teams — using the cheapest components from Asia-based chains — is misplaced,” he says. “We’ve got a tremendous amount of automation right here and a capability and capacity to deliver production parts immediately. We’ve got the technology, the ecosystem, plenty of untapped capacity, and an incredibly skilled workforce. We can change the paradigm. We should be the factory floor for the world.”

Related Content

When Handing Down the Family Machine Shop is as Complex as a Swiss-Turned Part

The transition into Swiss-type machining at Deking Screw Products required more than just a shift in production operations. It required a new mindset and a new way of running the family-owned business. Hardest of all, it required that one generation let go, and allow a new one to step in.

Read MoreTips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

Read More7 CNC Parameters You Should Know

Parameters tell the CNC every little detail about the specific machine tool being used, and how all CNC features and functions are to be utilized.

Read More6 Steps to Take Before Creating a CNC Program

Any time saved by skipping preparation for programming can be easily lost when the program makes it to the machine. Follow these steps to ensure success.

Read MoreRead Next

Die Maker Describes Five-Day Build for Tool Urgently Needed for Coronavirus Ventilator Production

Running 11 five-axis machines simultaneously, a die maker reduced a five week lead time to just five days. Here’s how.

Read MoreOne Auto Parts Supplier's Shift to Ventilators: Now Making 1000s of Parts per Week on Die Delivered in Days

GM applying its supply chain expertise to enable successes such as aiding this ventilator maker to expand sourcing for 700 parts.

Read MoreNew Business Plan Enables Shop to Increase Ventilator Part Production

KrisDee and Associates was able to increase production of a ventilator manifold from 90 parts per week to 780 parts per week thanks to changes the company started making months earlier.

Read More