Buying a Wire EDM, Part 1: How It Works

Wire EDMs can cut parts that require a level of accuracy, intricacy and fine surface finish that traditional machining methods cannot achieve. Here’s how it works.

This is part one of a four-part series about buying a wire EDM. For more on Wire EDM, click the links:

- Part Two: Wire Considerations

- Part Three: Speed, Accuracy and Finish

- Part Four: Dielectric Fluid & Maintenance

Find more insights about acquiring a new machine tool by visiting the Techspex Knowledge Center.

Wire electrical discharge machining (EDM) is widely used to create dies, punches, mold components, special tooling, extrusion dies, airfoils, gears, medical instruments, carbide cutters, toolholders, jewelry and thousands of workpieces too numerous to list.

Wire EDM’s Capabilities

Wire EDM can be used to cut electrically conductive materials to make parts that require a level of accuracy, intricacy and fine surface finish that traditional machining methods cannot achieve. A wire EDM unit can be programmed to cut complex shapes (small or large) to a dimensional tolerance of ±0.0001 inch and can be trusted to do so repeatedly and reliably. Unlike other types of machining, wire EDM exerts no cutting force on the workpiece and introduces no residual stress. There is little or no change in the mechanical properties of the material. Today’s wire EDM technology is capable of leaving virtually no thermal effects on the surface.

Wire EDM is best at cutting extremely hard materials such as tool steels, carbide, polycrystalline diamond (PCD), special alloys and parts requiring complex shapes, angles, tapers and sharp internal corners. Wire EDM can provide a surface finish as fine as 4 microinches Ra that may require no additional finishing or polishing. The wire EDM process leaves no burrs on the workpiece, a result that greatly reduces the need for subsequent operations. Wire EDM can be considered a time-saving, one-step process.

Wire EDM rarely calls for expensive workholding fixtures. One operator can run multiple machines.

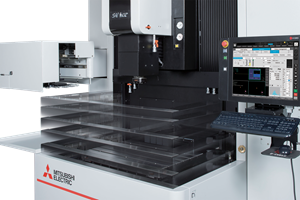

How Wire EDM Works

A typical system consists of a CNC unit, a power supply with anti-electrolysis circuitry, a mechanism for automatic wire threading, a tank to contain the dielectric fluid, a chiller to keep the fluid at a steady temperature and a filtration system to keep the dielectric clean.

Wire EDM uses an electrically charged strand of wire fed from a reel and moved through upper and lower guides. The wire is energized as it passes across a power contact at the top and bottom. The distance between the guides can be adjusted to accommodate the thickness of the workpiece. A tightly controlled sequence of electrical discharges between the wire and the workpiece creates hundreds of thousands of sparks per second to remove the workpiece material. The heat of each electrical spark, estimated at around 15,000-21,000°F, melts away a microscopic bit of the workpiece material. Although the volume of metal removed during this short period of intense heat lasting 1 millionth of a second or less it is quite small, the frequency and multitude of sparks is an effective method to cut a narrow slot through very hard materials. The action of the spark may also remove material from the wire at the same time.

Submerging the wire and part in deionized water allows cutting debris to be flushed away. Splash flushing can be used when the part cannot be fully submerged, but a top and bottom nozzle must be constantly directed at the wire to help wash away debris. When machining submerged, cutting occurs in a more easily controlled environment and the flushing nozzles need to be adjusted only once.

A CNC unit moves the machine in an X-Y plane and can position the upper guide independently in the U-V axis, giving the machine the ability to move all four axes (X, Y, U, V) simultaneously to cut tapers or shapes that transition from top to bottom. A programmable Z-axis enables workpieces with different thickness to be machined automatically.

Related Content

MC Machinery's Sinker EDMs Feature AI Adaptive Control

The artificial intelligence adaptive control technology is said to help optimize performance, improve productivity, reduce electrical consumption and take the guesswork out of estimating machining time.

Read MoreEDM, Laser Micromachining and More at GF Medical Demo Center

At GF’s Medical Center of Competence, the company shows off EDM and laser features that could make a large impact on medical manufacturing — and elsewhere.

Read MoreWall Colmonoy Acquires New Wire EDM From Sodick

The company will use the new wire EDM machine to increase capacity, improve cycle times, achieve tighter tolerances and improve surface finishes.

Read MoreYCM Sinker EDM Features Large Work Envelope

The Exeron 316 Sinker EDM features heavy-ribbed and welded construction for added strength and stability.

Read MoreRead Next

Buying a Wire EDM, Part 2: Wire Considerations

Each type of EDM wire has its strengths and weaknesses. This post reviews wire types, the importance of tensile strength and wire rethreading.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)