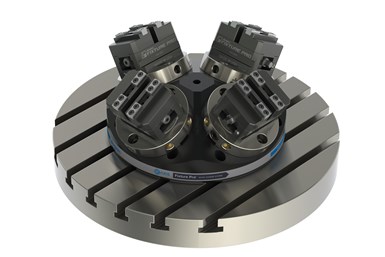

Jergens Pyramid Risers Provide New Angle for CNC Machining

Jergens’ pyramid risers feature a 30-degree mounting surface to ensure clearance for spindle and cutting tool paths, enabling more machining per setup.

Jergens Inc.’s three- and four-sided pyramid risers permit multi-part load and provide greater access for five-axis machining applications. Part of the Fixture-Pro line of quick-change modular workholding solutions, the pyramid risers feature a 30-degree mounting surface to ensure clearance for spindle and cutting tool paths, enabling more machining per setup.

These solutions offer three mounting options. Direct-to-table uses t-slots, a center pin and a timing key, and is secured using t-nuts and socket head cap screws (SHCS). Quick Locating System (QLS) mounts are designed to accurately locate and clamp the pyramid to a base element, such as a subplate, using a combination of QLS shoulder screws and SHCS. Quick-Loc pallet systems use pull studs (spaced at the industry-standard 96-mm pattern) to locate and clamp in a single step.

The lightweight aluminum risers are compatible with virtually all five-axis CNC machining centers and ensure fast changeover and setup times. Available in both three-position and four-position configurations, the pyramid risers are designed to mate with many top tooling choices including self-centering vises, dovetail vises and ER collet fixtures.

Related Content

-

Using Jaws as Grippers Enables Flexible, Low-Cost Automation

VersaBuilt’s automation systems significantly boosted Innovative Fabrication’s revenue. In return, the shop has helped VersaBuilt optimize its products.

-

When To Use A Collet Chuck

Don't assume the standard chuck is the right workholding for every lathe application.

-

A Case for Combining Workholding with Optical Scanning

Automotive dies and die inserts are often complex, one-off parts with little room for error. Integrity Tool's investments in modular workholding tools and 3D optical scanning have allowed the company to create niche capabilities for its CNC machined parts.