Cell Automates Multiple Part Change-Overs

An automated work cell on display in Okuma’s Booth S-8500 demonstrates not only robots loading and unloading parts, but also automated production run change-overs.

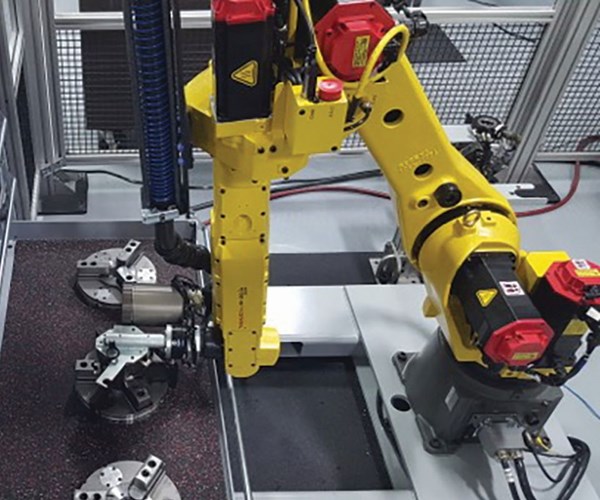

An automated work cell on display in Okuma’s Booth S-8500 demonstrates not only robots loading and unloading parts, but also automated production run change-overs. This means switching among a number of significantly different parts, not just members of a part family. In the cell, a Multus multitasking, CNC turning center performs a number of operations on a series of parts requiring three different three-jaw chuck face plates. A FANUC M-20iA industrial robot loads part blanks, unloads the finished parts and exchanges the chuck face plates as required.

Read the full story in the IMTS Show Daily.

Related Content

-

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

-

Using the Toolchanger to Automate Production

Taking advantage of a feature that’s already on the machine tool, Lang’s Haubex system uses the toolchanger to move and store parts, making it an easy-to-use and cost-effective automation solution.

-

Building a 5-Axis Cell

5-axis machining has taken over the metalworking industry, but what goes into a high-functioning 5-axis machining cell?