CAM Features Facilitate Five-Axis “Hog-Outs”

A point of pride for this shop is its ability to take on projects others wouldn’t touch. Recently, capabilities within Mastercam CAM software enabled the company to overcome challenges with a difficult aerospace component and, more significantly, to bring in new, similar work.

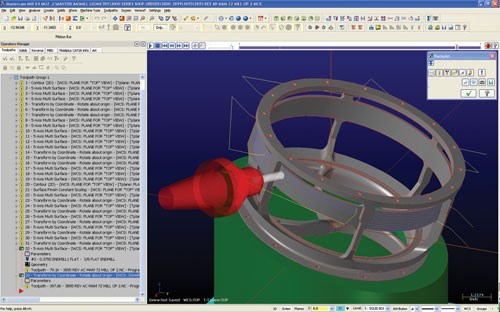

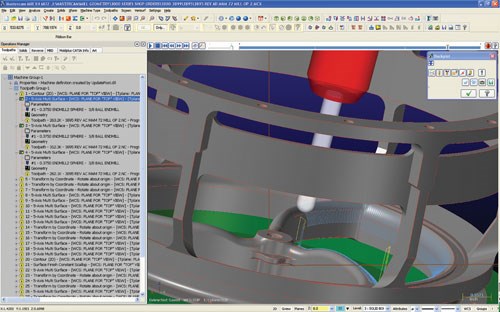

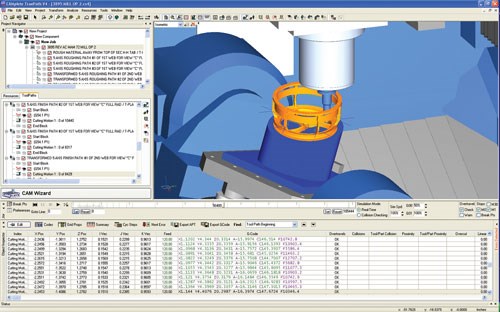

This video depicts the shop’s first “hog-out”—the complex aerospace component that led it to take on other, similar work—being machined on a Matsuura MAM72-633V five-axis machining center. As you watch the twists and turns of this complex operation, consider the behind-the-scenes factors that made this job a success. The part was programmed in Mastercam’s X4 software, which incorporates tools such as climb milling and dynamic milling with microlift that were essential for accessing deep cavities. Camplete Truepath software was employed to verify and optimize the program before posting, while Mastercam’s CAD features were essential to designing fixtures that could securely hold the thin-walled part without deformation.

It won’t be long before lead programmer Randy Barbe gets the latest release of his CAM software. His dealer will call him a couple weeks before it comes out to give him a heads-up on some of the features that will be most useful for his shop, MAC Machine. Once the upgrade comes in, he will spend some time with it almost every day, working through the examples and applying the most promising tool paths to existing jobs, until he has a good idea of how it will be able to help him.

Management at MAC Machine encourages Mr. Barbe to spend time exploring the advanced capabilities of the shop’s software and equipment because of the sophisticated nature of its business. The company specializes in advanced machining, primarily for surgical implant systems, medical diagnostic equipment and military and commercial aircraft components and assemblies. The ability to take on projects that others might not consider is a source of pride for the shop, and the difference that new CAM software features and capabilities can make in this endeavor is far from trivial.

Such was the case in 2008, when Mr. Barbe first got his hands on Mastercam X4 (developed by Tolland, Connecticut-based CNC Software) just in time for the software to help him solve a difficult aerospace part manufacturing problem. More significantly, the new software capabilities Mr. Barbe mastered to machine that part would come in handy later on similar components, which have since become a new specialty for the shop.

Characterized by deep, thin-walled, sculptured cavities, the complex part would have to be machined from a single billet of aluminum. To do so, the shop would need a way to securely hold the thin walls and accurately control the long, slender tools needed to reach deep inside the cavities. With help from CNC Software and Matsuura dealer Methods Machine Tools (Sudbury, Massachusetts), Mr. Barbe developed a precision CNC machining process using a five-axis Matsuura MAM72-63V multi-pallet system. High-stock-removal tool paths were applied to the CAD model in Mastercam and then imported into CAMPlete TruePath software to verify and optimize the process before machining. The customer was pleased with the result, as was Matsuura, which named the shop the winner of its 2008 International Five-Axis Machining Competition.

That project was the first in a line of similar components the shop would produce, a breed of parts Mr. Barbe refers to as "hog outs." These complex components are typically cast because of their inherent machining difficulties, but casting tooling often breaks or wears out before they are ready to be retired. That leaves the manufacturer with the prospect of continually repairing aging tools or purchasing new ones at a cost that might not be recovered for many years.

MAC Machine offers its customers the cost-saving alternative of hogging out the parts from full billets of material. In fact, a number of customers are now having the shop develop machining processes for parts produced using old casting tools long before those tools go bad. This is a win-win scenario—the customer doesn’t have to worry about fronting money for tooling used for parts entering sunset territory, and the shop doesn’t have to worry about casting deliveries. Moreover, the customer can make design modifications to parts without worrying about rebuilding the tooling.

The key to profitably producing such parts is the use of tool paths that can remove large amounts of stock quickly. Mr. Barbe says the shop’s first "hog out," the award-winning part, would have been very difficult to machine without Mastercam’s five-axis tool paths. "The timing worked out really well because that is when CAMplete came out with their version 4, and Mastercam included advanced multi-axis tool paths in its new release," he recalls. "If it weren’t for those tool paths, I would have had a real struggle with that part. The whole algorithm is extremely useful." He adds that if the tool path does not initially perform the way he wants it to, he can work in solids to clean up, change surface blending or otherwise manipulate features so that the CAM software can generate a cleaner tool path.

Mr. Barbe also cites a number of other CAM software features as helpful in the high-stock-removal machining required for "hog outs:"

• Microlifts: Included in Mastercam’s 2D Dynamic Milling tool path, which is used for pocketing, the microlift feature retracts the tool by a small, user-defined distance (perhaps 0.01 or 0.02 inch) instead of fully retracting from the pocket when the program calls for a move. This minimizes air cutting and improves productivity by keeping the tool engaged with the workpiece as often as possible during machining.

• Monitoring for Climb Milling: The software monitors and adjusts tool engagement to avoid excessive stress on the cutter, particularly when it arrives at a corner. Reduced engagement prevents slamming into corners and damaging the tool or workpiece or dislodging the part from the fixture. This is particularly effective for climb cutting, in which tool rotates in the same direction as it feeds.

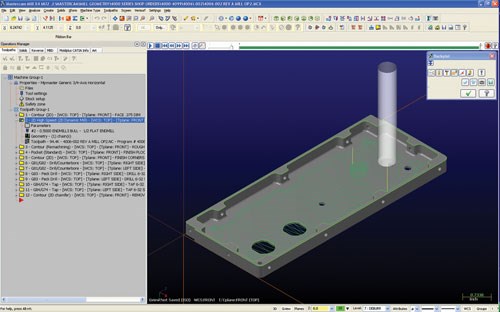

• Fixture design: Mr. Barbe uses the software’s CAD module to design fixtures that both hold the part securely and present it at the unusual approach angles required to minimize steps during multi-axis machining.

• Simulation: Mr. Barbe can visualize parts, fixtures and tool paths within the same CAM programming environment. The software’s Verify feature provides a color-coded representation of how much material has been removed at a given stage of manufacturing. He saves this as an STL file so that he can use it again without regenerating it. "We save the STL files and manipulate them for the next operations," he explains. "By the time we’re done, we have a visual model of a completed part. We use these files to find gouges, nicks and inapppopriate toolpath overlays."

Backplot is another frequently used simulation feature. This provides Mr. Barbe with a computer animation of all tool movements and a close approximation of actual machining time.

These capabilities have improved results on the shop floor, Mr. Barbe says, citing faster setups, faster cycle times and fewer tool breakages and machine crashes. "We have been relying on it so much that we brought in a second programmer, and now we need a third," he notes.

Although he hasn’t yet seen another part as complex as the original, award-winning "hog-out," Mr. Barbe says he could produce another such component in about half the time. Regardless, the new software capabilities he mastered for that part have saved the company a great deal of money by increasing productivity on other, similar projects. In the end, the time spent learning was well-invested.

Related Content

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreWhy Go Five-Axis: Machine Types and Benefits

Even as the benefits of five-axis machining stack up year by year, the barrier for entry crumbles.

Read MoreWatchmaking: A Machinist’s View

Old-world craftsmanship combines with precision machining on a vertical machining center and Swiss-type lathe to produce some of the only U.S.-made mechanical wristwatch movements.

Read MoreRead Next

Obscure CNC Features That Can Help (or Hurt) You

You cannot begin to take advantage of an available feature if you do not know it exists. Conversely, you will not know how to avoid CNC features that may be detrimental to your process.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)