An Indexable Insert

The solid end mill is a machine shop staple. Its positive cutting edge removes metal by slicing through the material, rather than by scraping.

The solid end mill is a machine shop staple. Its positive cutting edge removes metal by slicing through the material, rather than by scraping. This reduces cutting forces, power required to make the cut and the possibility of inducing vibrations. These reasons are why solid end mills remain popular for low-horsepower machine tools with limited structural mass to damp vibrations.

Solid end mills do require periodic regrinding, and there is a limit to how many times this can be done to a tool. As an alternative, manufacturers have designed indexable insert end mills with positive radial and axial rake angles to emulate the solid end mill's cutting action, while allowing insert indexing and changeout. Until recently, though, a key feature of the solid end mill—eccentric relief, or "margin"—has not been replicated in an indexable insert cutter.

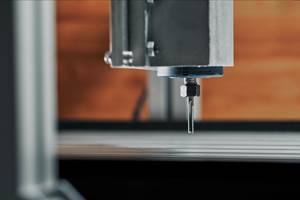

Big Daishowa Seiki has developed what is says is the first indexable insert end mill to combine positive/positive rake angles with eccentric relief, a la the solid end mill. We had the opportunity to preview the company's Fullcut end mill while visiting its manufacturing facilities and technical center located on Awaji Island, just off the coast of Osaka, Japan. Now available in the United States from Big Kaiser, Big Daishowa's partner located in Elk Grove Village, Illinois, this end mill design combines smooth, low-force cutting with insert changeability, while eliminating regrinding.

Eccentric relief is the positively arched (convex) area behind the cutting edge, as shown on the right-hand image in Figure 1. The profile brings the insert's sharp cutting edge nearly even with the body diameter to provide greater edge support. Unlike a concave, negative profile with a high clearance angle that tends to cantilever the insert from the body, eccentric relief more effectively directs the forces from the cutting edge into the tool's body. This geometry is less likely to cause insert chipping, which is prone to occur at the start of a cut (when cutting forces are highest) or during interrupted cuts.

Lower cutting forces can permit higher speeds and feeds, without increasing the risk of chipping. The Fullcut's insert geometry allows for shoulder, slotting and facing operations, but it can't be used for Z-axis feeding operations, such as plunge cutting or boring.

The end mills range in diameter from 0.5 inch to 2.0 inch, with inserts tailored to each diameter to maintain proper geometry. Each insert can be indexed once. The end mills are available in straight shank and integral body designs (V-taper, HSK and Capto) for high rigidity.

Related Content

3 Examples of Machines that Combine Manufacturing Methods

Certain “hybrid” machines combine some form of additive manufacturing with CNC subtractive manufacturing. Columnist Mike Lynch, President of CNC Concepts Inc., explores three types of these machines here.

Read More5 G-Code Tips for Increasing CNC Efficiency

Optimizing G code is a low-cost way to improve CNC efficiency without sacrificing usability and safety.

Read MoreWhen Handing Down the Family Machine Shop is as Complex as a Swiss-Turned Part

The transition into Swiss-type machining at Deking Screw Products required more than just a shift in production operations. It required a new mindset and a new way of running the family-owned business. Hardest of all, it required that one generation let go, and allow a new one to step in.

Read MoreFive Safety Considerations for CNC Machinists

Safety in CNC environments is essential for users – and for productivity. Consider these 5 points to avoid injury, part failure and downtime.

Read MoreRead Next

Obscure CNC Features That Can Help (or Hurt) You

You cannot begin to take advantage of an available feature if you do not know it exists. Conversely, you will not know how to avoid CNC features that may be detrimental to your process.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.jpg;width=70;height=70;mode=crop)