Drill Cuts Cycle Time, Costs By More Than 60 Percent

This supplier of engineered gear and drive systems had problems with tool life and lengthy cycle times when drilling holes on a large drive shaft made of forged alloy steel. A new drilling system resolved these issues and exceeded the company's expectations.

Oerlikon Fairfield Drive Systems supplies engineered gear and drive systems to off-highway and industrial equipment manufacturers from around the world. As a branch of Oerlikon, the Lafayette, Indiana-based company specializes in the design, development and manufacture of custom gear and drive assemblies for numerous industries, including construction, mining, rail, transportation and agriculture.

Fairfield vies with both foreign and domestic machine shops to stay at the forefront of the industry. To remain competitive, the 88-year-old company constantly seeks ways to streamline its production process. When Fairfield began experiencing issues with producing drive shafts for mining equipment, the company realized that finding an effective solution to its problematic production process would be vital to its success.

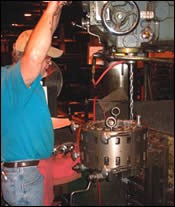

The problem involved a large drive shaft constructed of forged alloy steel. The company ran this application on a Carlton Radial Arm Drill with water-soluble coolant using a rotary coolant adaptor (RCA). The operation required drilling 10-inch deep, 0.787-inch diameter holes. To machine the holes, the company used a cobalt twist drill and a fixture plate with 0.787-inch bushings in a process that took 17 minutes, 33 seconds. This lengthy cycle time limited productivity and drove up costs, leading the company to search for a quicker solution.

Fairfield consulted Allied Machine & Engineering Corporation. Allied field sales engineer Chad Longstreth, along with Indianapolis-based distributor Carbide, Cutting Tools, and Abrasives Inc. (CCA), brought in Allied’s GEN2 T-A drilling system to address the company’s concerns. Since this implementation, the company reports that the 0.787-inch drill insert exceeded its expectations.

Featuring a chrome helix holder, the new insert uses a bushing fixture for guidance when the tool transitions from one set of holes on the top of the part to another set of holes on the bottom.

“The bushing simply keeps the holes in line,” Mr. Longstreth explains.

Another feature designed to maintain hole straightness is the insert’s custom notch-point geometry. The insert’s design, coupled with its custom AM200 coating, increase tooling life and drill stability, the manufacturer says. In addition, the tool is designed to provide smooth breakouts in through-holes while improving chip formation.

Addressing the benefits of the GEN2 T-A tooling, Mr. Longstreth explains, “The previous process was very tedious, and tool life was minimal. Additionally, the tool required frequent re-sharpening, which detracted from machining and therefore added to production costs.”

With the capability to drill 24 holes before wear sets in, the new drill is an obvious upgrade from the previous tool, which lasted for only ten holes, the company says. The tool reduced the operation’s cycle time by nearly 64 percent to only 6 minutes and 35 seconds.

This cycle-time reduction and longer tool life has created a substantial cost savings for Fairfield. The company lowered its costs by roughly 63 percent when drilling 600 holes with the new tool, a savings that amounted to thousands of dollars.

“Having the ability to make it through an entire part without changing the drilling insert maximizes uptime and minimizes costs,” Mr. Longstreth concludes.

Related Content

How to Tackle Tough Angled Pocket Milling With Two Tools

Milling a deep pocket with a tight corner radius comes with unique challenges, but using both a flat bottom drill and a necked-down finishing tool can help.

Read MoreNew Modular Tool Options for Small Spindle Milling

Tooling options have been limited for small spindle milling applications. Now modular, indexable systems are available that provide broad flexibility to get the right cutter for the job with less inventory and at lower cost.

Read MoreKay Engineering's Gundrilling Machine Performs Range of Operations

Kay Engineering’s DeHoff 20144 is used to perform gundrilling, pull boring, roller burnishing and thread tapping.

Read MoreHow to Turn Machine Shop Downtime Into Process Expertise

To take advantage of a lull in business, JR Machine devised a week-long cutting tool event that elevated the shop’s capabilities with aerospace alloys.

Read MoreRead Next

Using Automation to Reduce COGS and Stay Globally Competitive

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

Read MoreObscure CNC Features That Can Help (or Hurt) You

You cannot begin to take advantage of an available feature if you do not know it exists. Conversely, you will not know how to avoid CNC features that may be detrimental to your process.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)