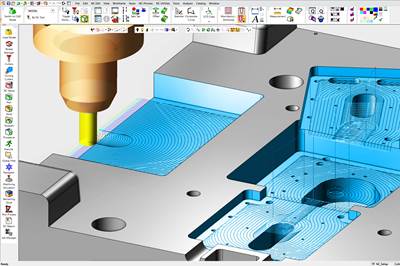

Die/Mold Machining

Die/Mold Machining primarily refers to the machining of complex 3D forms. Stamping dies, forming dies, forging dies, injection molds and blow molds are all examples of tooling that might have complex shapes precisely mirroring or matching the intended shape of some final, mass-produced part. Complex fixtures and composites layup tools are also examples of milled parts that might have a similar complex 3D shape. High speed machining is an important topic for die/mold machining, because of the need to take light milling passes productively in order to realize both the required geometry and the required surface finish. Hard milling is also important because many workpieces are machined in their hardened EDM is also used to impart the shape into the final die or mold tooling.

Takumi USA

Featured Content

View More

Latest Die/Mold Articles

VIEW ALLLyndex-Nikken Collets Enable Accurate Small-Diameter Cutting

The MMC Mini-Mini collet chuck is well suited for high-speed machining applications where clearance is needed, such as die mold, aerospace and medical parts.

Read MoreIn Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

Read MoreGrob Systems Inc. to Host Tech Event With Industry Partners

The 5-Axis Live technology event will highlight new machining strategies for optimizing the production of complex medical, aerospace and mold/die parts.

Read MoreFor This Machine Shop, Licensing Is the Answer to the Inventor’s Dilemma

Machine shops are natural inventors, but not necessarily suited to supporting and marketing a product. This Minnesota shop with an invention related to micromolding will share it through licensing.

Read MoreCimatron's Updated CAD/CAM Software Streamlines Mold Design

Eastec 2023: Cimatron V16 includes a clean new user interface and increased automation for faster mold design, electrode creation and NC programming.

Read MoreTwin Spindle Design Doubles Production of Small Parts

After experiencing process stalls in the finishing stage of production, Bryan Machine Service designed an air-powered twin spindle and indexable rotating base to effectively double its production of small parts.

WatchLatest Die/Mold News And Updates

YCM Alliance Hits IMTS

YCM Technology has joined with other like-minded machine tool manufacturers to take a solutions-based approach to manufacturing.

Read MoreTool and Die Shop Discovers New Opportunities With First CNC Machine

In a shop that stamps millions of parts per year, the arrival of a CNC machining center is opening new pathways for production and business.

Read MoreHexagon Acquires TST Tooling Software Technology

Hexagon acquires TST Tooling Software Technology, a distributor of VISI, Hexagon’s CAD/CAM software for the mold and die sector, and PEPS CAM software.

Read MoreStars Slowly Align for Small Shop Merger

RPM Tool’s seemingly overnight expansion from a five-person machine shop to an almost 30-employee production business involved over a year and a half of planning.

Read MoreIncrease Profitability 17% with Exporting

This short tutorial will empower you to find the right market for your product, ensure you get paid, and provide resources to get started. (Sponsored)

WatchAcme Receives National Metalworking Reshoring Award

The National Metalworking Reshoring Award honors companies that have effectively reshored products, parts or tooling made primarily by metal forming, fabricating, casting or machining, including additive manufacturing.

Read MoreFeatured Posts

Functional Injection Molds (and More) from 3D Printed Metal Paste

A 3D printing process from Mantle shapes extruded metal paste before it is sintered, dramatically reducing the time from print to finished part.

Read MoreNew Machining Centers Improve Moldmaking Workflow

Westminster Tool has shifted the workflow in its moldmaking department to incorporate high-speed five-axis and, as a result, cut lead times and reduce the need for wire EDM.

Read MoreWeingärtner Mill-Turn Widens Plasticizing Screw Production Range

Weingärtner’s custom Pick Up mill-turn center for injection mold machine manufacturer Arburg has widened the range of plasticizing screws Arburg can produce.

Read MoreDie Makers Adapt to Challenges All Machine Shops Face

Die shops offer examples of adapting to the skills shortage and excelling at difficult machining. Plus, why reshoring should begin with die tooling.

Read MoreUse Your Machinists to Make Dies

By systemizing die making into repeatable steps, Dies Plus, a division of Otto Engineering, is using its machinists to effectively make dies. This solution relies on a paperless color-coding system to convey the tolerances machinists need to hit in order for tool and die makers to do the final fitting.

Read MoreVideo: The Importance of Reshoring Mold and Die Manufacturing

The die and mold tooling sector controls a manufacturing market more than 10 times larger than the market this tooling is used in. Experts discuss why the price savings of offshoring tooling misses the total cost of sending tooling work away.

Watch

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)