Cutting Tools

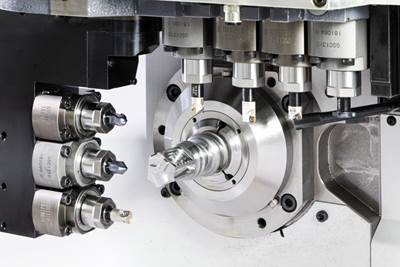

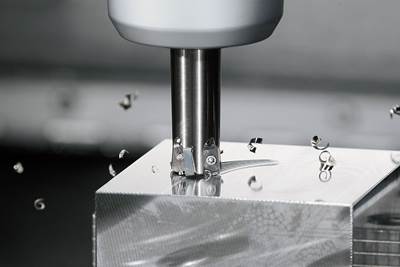

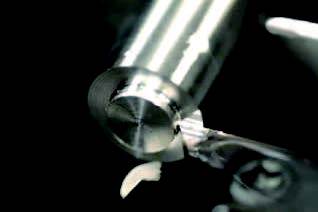

The broad category of “cutting tools” includes all of the consumable tooling involved in milling, drilling, turning and other lathe and machining center operations. Drills, end mills, taps, reamers and inserts are all included here. Consumable tooling used on certain other types of machine tools is included here as well. Also found here are toolholders and closely related accessories such as angle heads. Supplier pages, FAQs related to cutting and cutting tools can be found here, as well as essential reading on the topic and all of the latest Modern Machine Shop cutting tools coverage.

Hwacheon Machinery America, Inc.

Featured Content

View MoreLatest Cutting Tools News And Updates

H.B. Carbide Grade Improves Edge Security in High-Temperature Applications

H.B. Carbide Co. introduces the HB-710 grade for the machining of high-temperature materials, increasing edge line security and resistance.

Read MoreTungaloy Cutting Inserts Enhance Internal Grooving Operations

Tungaloy-NTK America Inc. introduces the STV type insert for its TungShortCut internal grooving tool line, enhancing internal profiling and machining of complex shapes or narrow areas.

Read MoreEmuge-Franken's TIN Coated Thread Gages Improve Wear Resistance

Emuge-Franken USA expands its precision thread gages line with TIN coated gages featuring 3B class-of-fit.

Read MoreSandvik Coromant Parting, Grooving Concept Improves Stability, Chip Control

Sandvik Coromant’s CoroCut 2 with -RF geometry is designed for secure and high-precision profiling, eliminating the trade-off between chip control and optimized surface finish.

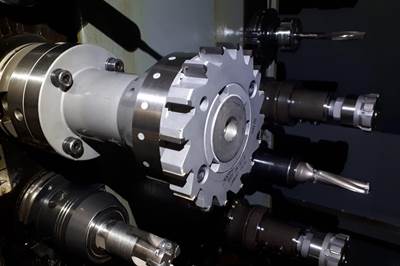

Read MoreHorn Milling Tool Features Modular Design for Quick Changeovers

The DG modular interchangeable head milling system optimizes the interface between the cutting head and shank for greater versatility, stability and higher changeover precision.

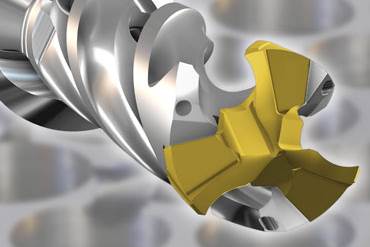

Read MoreCeratizit Milling Tool Enables Dynamic Positioning

Ceratizit USA’s FreeTurn tool is designed to provide dynamic turning capabilities with its slim, axial structure.

Read MoreFeatured Posts

Finding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read MoreTooling Displays Now More Hands-On

Horn USA’s new booth concept is designed to enable attendees to (literally) get a better feel for its various tooling offerings.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreShoulder Milling Cuts Racing Part's Cycle Time By Over 50%

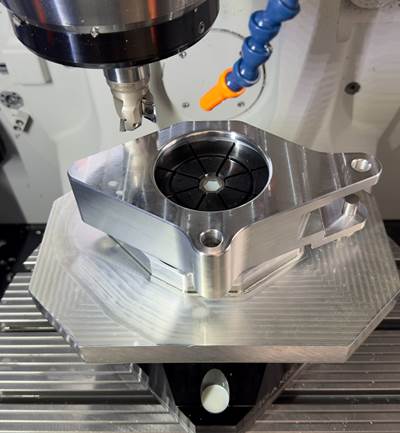

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

Read MoreBroaching Tool Technology For Lathes Used to Slot Inconel Parts

This shop finds value in using an indexable-insert-style broaching tool to create blind-hole slots in heat-treated Inconel aerospace parts on a CNC lathe.

Read MoreBriquetting Manufacturer Tools Up for Faster Turnaround Times

To cut out laborious manual processes like hand-grinding, this briquette manufacturer revamped its machining and cutting tool arsenal for faster production.

Read MoreFAQ: Cutting Tools

Why is through-tool coolant valuable, and why are shops are seeing greater need for it?

Getting coolant to the cutting edge is critical for any manufacturing application. It helps in cooling the cutting zone, provides very needed lubrication, and can assist in breaking a chip. Many times, external lines are used to splash coolant near the work zone. Long Chips can easily interfere with this delivery method, possibly knocking the lines out of the way. Additionally, when tools need to be changed or indexed coolant lines might be moved for better access to the tool. Then when the line is put back it is never the same as it previously was. Often times there is a give-and-take methodology used to cover areas being machined with this coolant, so all tools get some cooling, but none of them get ideal cooling. A coolant-through tool allows pinpoint accuracy with a specific direction of coolant pointed exactly at the cutting zone.

Through-tool coolant is available on cutters that couldn't offer it before. What has changed in the technology of tool manufacturing to make this possible?

There’s been a big change is the ability to drill small-diameter holes very deep and do this in a production atmosphere. Part of this comes from the drilling machines being able to reach the necessary speeds and holders that provide superior clamping and runout. The other part comes from tools designed specifically for this drilling application.

On a coolant-through tool, material could be added in areas that may need additional strength, allowing for the intersecting coolant ports to be drilled accordingly.

What aspect of tool engineering is responding to greater cutting speed?

Machines and tools seem to have a back-and-forth dance in terms of which is leading. Coatings continue to evolve, with more layers, and different material being used. This is something all tool manufactures are playing with on some level. The changes in coating technology is somewhat more limited, and not as many are playing in this arena. One process that comes to mind is “HiPIMS,” or high-power impulse magnetron sputtering. This process uses microsecond timing of extreme-power pulses. This allows the metal to ionize to nano size particles to be deposited on the tools. This process allows for greater adhesion and coating hardness, while maintaining great lubricity. Additionally, this process has greatly reduced compressive stresses. This reduction allows for smaller edge preps to be used, thus resulting in sharper tools.

Why is diamond used as an industrial cutting tool?

Developments in polycrystalline diamond (PCD) and cubic boron nitride (CBN) have allowed these materials to improve in ways that make them more versatile and cost-effective. Meanwhile, the machining speed and tool life of these tools continue to take machining processes to levels of performance where carbide cannot go.

Through long tool life and fast cutting parameters, the tools increase machine capacity by reducing the frequency of tool replacements and allowing machines to make parts at a greater rate. Meanwhile, the tooling increasingly figures into expert solutions tailored to more demanding applications in various industries.

Source: The New Rules of Cutting Tools - Rule #3: Diamond Shouldn't Be Rare

What are cutting tools made of?

Polycrystalline diamond (PCD), cubic boron nitride (CBN), ceramic, high-speed steel (HHS), cemented carbide or cermet.

Sources: What's Happening With Cutting Tools

Cutting Tools Supplier Categories

- Deburring Tools (Machine Tool Spindle-Mounted)

- Collets, Solid & Master

- Milling Cutters

- Tap Drivers & Attachments

- End Mills

- Tool Presetters

- Boring Tools & Heads for Machining Centers

- Spline Rolling Tools

- Tooling Materials, Ceramics

- Drills

- Drill Bushings

- Diamond Tools

- Mass Finishing Media & Compounds

- Spline Inserts

- Shear Blades

- Threading Tools - Cutting

- Facing Tools/Heads

- Grinding Wheels & Belts

- Thread Chasers

- Boring Tools

- Punching Tools/Dies

- Collets for Toolholding

- Gear Cutting Tools

- Cut-Off Tools/Attachments

- Grooving Tools

- Tool Repair, Coating & Treatment Services

- Thread Whirling Tools

- Key Seating Tools

- Tooling Materials, Carbides

- Broaching Tools

- Taps

- Slotting Saws

- Thread Milling Cutters

- Endworking Tools

- Tool Blanks

- Burnishing Tools (Roller)

- Grinding Wheel Dressing Units

- Retention Knobs

- Drilling Heads/Attachments

- Threading Tools

- Tool Conditioning Equipment

- Honing & Lapping Tools

- Serration Tooling

- Protective Sleeves & Coatings (for Cutting Tools)

- Milling Heads/Attachments

- Tool Condition Monitoring Systems

- Form Tools

- Tool Storage & Handling Systems

- Gear Rolling Tools

- Gundrills

- Burnishing, Honing & Lapping Tools

- Saw Blades

- Die & Mold Components

- Buffing & Polishing Supplies

- Knurling Tools

- Arbors (for Cutters)

- Cold Heading Tools

- Counterbores/Countersinks

- Abrasive Compounds & Slurries

- Marking Tools

- Shaving Tools

- Boring Tools for Turning Machines

- Reamers

- Tooling Systems, Modular and/or Quick-Change

- Drill Chucks

- Toolholders

- Chamfering Tools

- Thread Rolls & Dies

- Threading Tools - Forming

- Inserts, Indexable (Carbide, etc.) & Tool Inserts

.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)