Share

ECi Software Solutions, Inc.

Featured Content

View More

Companies usually strive to capitalize on their expertise and uniqueness. So, when a design and engineering firm for micro-manufactured parts realized it could help its customers more efficiently by bringing machine tools and laser machining equipment in-house to program and cut test parts, the company owner knew it was the right move to make. Grzegorz (Greg) Nowobilski would come to understand this was an opportunity for growth in this niche manufacturing space because not many CNC machine shops have the capability to produce these very small, intricate parts.

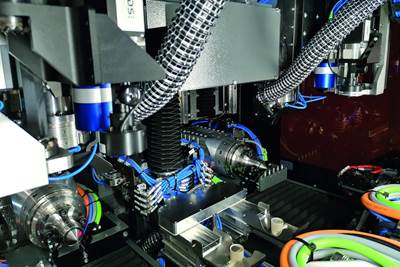

In fact, while working as a consultant for GF Machining Solutions, Nowobilski helped design the GF Machining Microlution ML-5 femtosecond micro-laser machine. Now, he has one five-axis scan unit with 3D positioning and one three-axis motion model in his own machine shop, Sunlight-Tech Inc. in Mokena, Illinois. These micro-laser machines designed to machine small parts have expanded the company’s services by enabling the production of complex parts that often cannot be created on a traditional CNC machine or wire EDM machine.

“For blind features, we can cut 5 to 10 microns deep on the ML-5,” Nowobilski says. “But we can’t do that on a standard CNC milling machine. It is perhaps possible on EDM machines, but the feature quality would not come close to the quality the ML-5 Femtosecond Laser is capable of.”

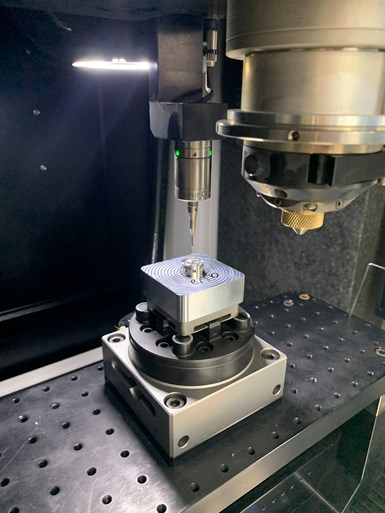

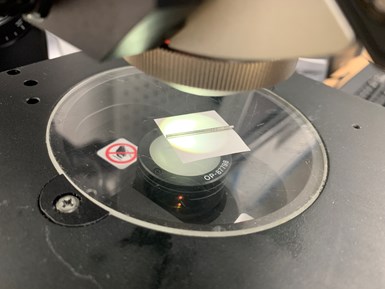

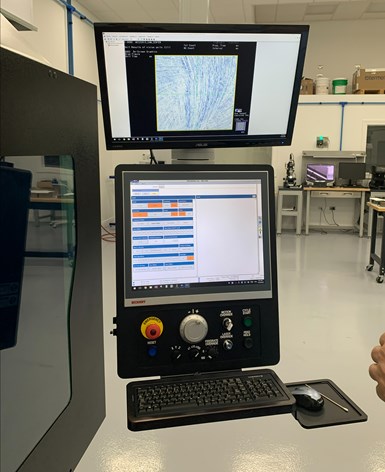

The shop’s ML-5 is equipped with a probe for part measurement in the machine. Nowobilski says if they are cutting a part that cannot be measured with the probe, the camera inside the machine can scan the surface of the part. “I can measure the hole to find the center, and the camera will take a picture of the center of the hole,” he explains. The picture is then displayed on the monitor above the HMI.

While holding tolerances typically in the 1- to 5-micron range, Sunlight-Tech’s micro-laser machines enable cutting of very small or blind holes and intricate shapes in all metals, ceramics and other materials. The shop mostly cuts stainless steel for its customers in a variety of industries. The technology, which can be fully automated, can often machine an entire part in one operation, eliminating secondary ops. It also has enabled the company to enter new markets, as well as reduce the cost of manufacturing parts for new customers previously manufactured in a more conventional machining process.

Cutting its Teeth on Micro-Milling

As a consultant prior to opening Sunlight-Tech, Nowobilski began working with a team of engineers at GF Machining Solutions/Microlution in 2010 on the company’s micro-milling machines, experimenting with cutting automotive stainless-steel parts, which evolved into building several other machines and creating a relationship still in place today. As customer requests evolved, the need for more space presented itself, and so did the need for CNC milling machines to complete precision parts for the customers’ systems. In 2018, the company moved into a larger facility with a shop floor and gradually purchased three Kitamura CNC milling machines, one Okuma lathe and a Micro Dynamics 4+1 axis CNC machining center. Hence, Sunlight-Tech was born.

The same year, the shop purchased its first Microlution five-axis scan unit with 3D positioning to enhance its capabilities. It used the machine for R&D and manufacturing contract parts for its customers, and two years later it invested in another one, only with three axes instead of five.

The shop’s ML-5 is equipped with a probe for part measurement in the machine. Nowobilski says if the shop is cutting a part that cannot be measured with the probe, the camera mounted inside the machine can scan the surface of the part, enabling program capabilities beyond standard measurement. Surfaces untouchable by a probe can be scanned with the camera to find feature characteristics for feature positions within themselves or stand alone as measurements. “I can measure the hole to find the center, and the camera will take a picture of the center of the hole,” he explains. The picture is then displayed on the monitor above the HMI.

When Sunlight-Tech was gaining ground at the start of its business, it was outsourcing its parts for secondary ops. However, the turnaround time was too slow for its customers. So the shop opted to offer all operations in-house and purchased three Kitamura CNC milling machines as well as other machine tools.

Besides its two femtosecond laser machines, the shop now also houses a Microlution 5100 five-axis micro-milling machine. The machine is used to produce miniature parts that cannot be cut on the CNC machines, as well as create precision fixturing for parts run on the ML-5s, according to Nowobilski.

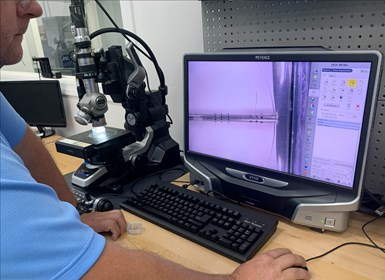

All three Microlution machines — the two micro-laser machines and one micro-milling machine — sit in a temperature-controlled room behind closed doors at Sunlight-Tech. Quality equipment for parts produced on these machines include a Zeiss O-Inspect CMM and two Keyence microscopes, which are also kept in this room.

Unconventional Small Part Machining

Sunlight-Tech, which has built a customer base that includes industries such as medical, watch, automotive, aviation, space and more, has micro-laser machining capabilities that go beyond the limitations of traditional CNC machines and EDM machines. The five-axis femtosecond laser on the ML-5 creates burr-free micro features other than round shapes on practically any material, while holding tight tolerances that cannot be achieved at most precision turning shops.

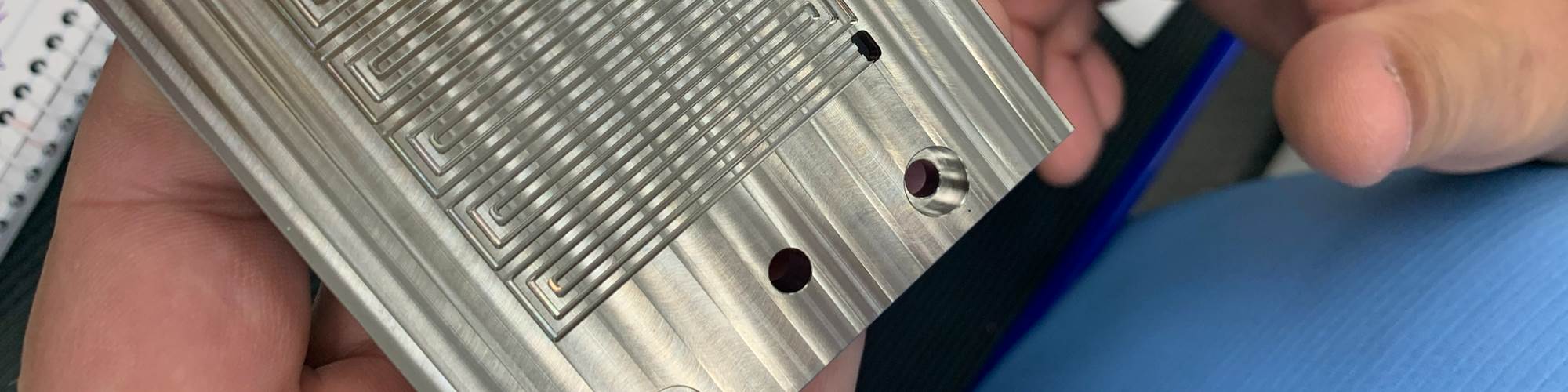

For example, normally holding tolerances between 1 to 5 microns, the shop can create through holes with positive and negative tapers and straight walls with the ML-5. It can also cut unique shapes on a part such as a circular entrance with an elliptical exit. Cutting squares, triangles, star patterns and other obscure shapes is also possible.

The greatest advantage to using the GF machines is the capability to create such complex shapes and the quality of the parts. Everything from watch gears and filtration systems to springs can be laser machined with tight tolerances between 1 to 5 microns on the ML-5.

While most laser machines have the capabilities of creating unique shapes, the ML-5 was created specifically for complex, microscale part machining at the speed of serial production. “This machine was designed from a blank sheet of paper for maximizing thermal stability and inertial stability with the goal of rapid acceleration,” explains Mike Lerner, head of sales, laser at GF Machining Solutions. “Rapid acceleration is what’s needed for producing small parts.”

However, because of the complexity of the micro-laser machine, they are not designed for high-volume batches that many precision machine shops produce. “We can do a couple of thousand parts in one batch, no problem,” Nowobilski says. “But if those batches go up to 100,000 parts, then that is something we don’t have the structure for.”

Unconventional Results

Sunlight-Tech benefits from the structure of the micro-laser machines in many ways that are unique to this process. According to GF Machining Solutions, this technology can be up to three times faster than conventional machining processes because of the lack of obstacles and pain points that often plague CNC machines by design.

For instance, the micro-laser machines have high accuracy and repeatability because the micro-laser process does not involve any traditional tooling, which means there is no tool wear nor cross contamination. In fact, one laser can last five to 10 years.

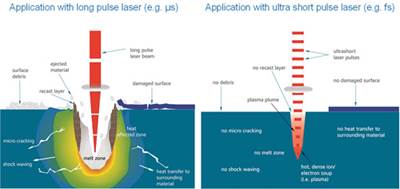

The machining process also does not generate heated

zones within the machine. The built-in cooling system (which consists of fans, heat exchangers and cooling circuits throughout the machine) stabilizes temperatures for steady axis motion.

Also, the lack of metalworking fluids within

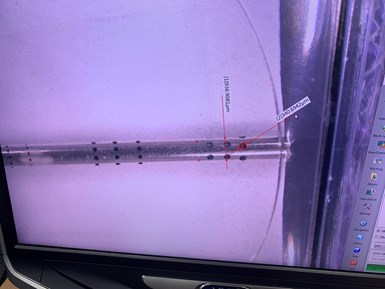

This small metal tube with tiny holes can be viewed clearly with one of the shop’s Keyence microscopes. The device measures hole sizes to ensure part accuracy for its customers.

the machine creates very clean parts. This is especially beneficial when machining sensitive parts that come with stringent cleaning specifications such as those for the medical and automotive industries.

The ML-5 also yields a better surface finish than CNC-machined parts, according to Nowobilski. The Z-axis movement in the machine equipped with the femtosecond laser delivers precise drilling, cutting and micromachining that traditional CNC cutting tools are not capable of generating. Plus, the five-axis motion within the machine can control laser tapering, resulting in burr-free parts.

3-Step Programming

Programming and setup for the ML-5 machines is more involved than programming a typical CNC machine, according to Nowobilski. There are three different programs to set up prior to machining. And, depending on the tolerances to be held, it can take days to set up the program to machine a single hole.

First, the laser must be adjusted to proper settings. Next, the laser scan head is set up and programmed to cut the required feature. Third, the machine itself must be programmed using G code for positioning the features and to know when to turn off and on. Nowobilski explains that prior to this setup process, communication with customers is crucial to achieve the most accurate features in an efficient process. Once Sunlight-Tech gets the green light after R&D test cut inspection from the customer, the shop begins to machine with the customer’s material for best results.

This setup process can take from one to several days to complete. Kelsey Humble, applications engineer at Sunlight-Tech, describes the typical time frame. “Getting down to 1 micron takes more time to make sure the machine is stabilized,” she says. “It can take four to five days for one hole at that tolerance. Submicron tolerances take longer, but is doable.”

Although there are three different programs to develop on the ML-5 micro-laser machines, Kelsey Humble says the Microlution software in general is user friendly. “Working with the programs, it makes it easier to go from one project to the next or start a new project because I’m able to use similar setups,” she says. She says this enables her to use her time more efficiently.

Although some tolerances customers require cause setups to be rigorous, Humble says the ML-5 is generally user friendly. She explains that transitioning from one project to another is simple on this machine because she can often use similar setups and the changes she needs to make can be done quickly on the HMI.

With a background in CNC machining, Humble was able to learn how to program and operate the machine in three months. “What impressed me about the machine is all that you can do with it,” she says. “There are so many options and changes you can make to the program. I haven’t even gotten a chance to play around with all the things available on the machine.”

Plus, with all the opportunities the ML-5s have afforded the shop, Nowobilski is planning to purchase more of these machines as soon as the ones he owns reach capacity. He believes the future success of the company lies in laser machining.

“With this machine, we’ve entered into different fields of engineering for military contracts and aviation,” Nowobilski explains.

Sunlight-Tech Inc. is also ISO 9001:2015 certified and expects to be AS9100 certified by early spring 2024.

More From This Author

Lori Beckman is senior editor of MMS’ sister brand, Products Finishing. Lori has been a writer/editor for Gardner Business Media since 2004 and wrote this article when she was on the staff at Production Machining, another GBM brand. For more articles from Lori, SUBSCRIBE HERE.

Related Content

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreHow to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreRead Next

Laser Technology "Turns" into a Turning Tool

This new technology uses a laser to act as a cutting tool to "turn" parts from solid barstock. This high-speed precision turning machine is especially useful for micromachining, enabling high accuracy for small, complex parts that are often delicate and difficult to machine when implementing conventional turning processes.

Read MoreMicromachining is About Precision

Holding tolerances on very small part features is not for the faint of heart. The skill is not only in the machining, but cleaning and inspection as well.

Read MoreFemtosecond Laser Processing in the Medical Device Industry

Recent advances in the laser technology have brought improved capabilities for precision machining—no thermal effects and minimal post processing.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)