Automating low-volume, high-mix, high-complexity parts isn’t just possible — it’s profitable. Précinov, a precision machine shop based in Lévis, Quebec, has managed to double sales by adopting bar feeders and PartNR systems engineered by Mirabel, Quebec-based automation provider Waybo.

When Mathieu DeBlois (right) was choosing his automation supplier, Jean-Sébastien Neveu (left), president of Waybo, demonstrated the simplicity of his company’s robotic cells by picking up a robot from his garage, driving it across Montreal to Précinov and setting it up on the spot. Images courtesy of DGS Marketing.

Production or Job Shop? Both.

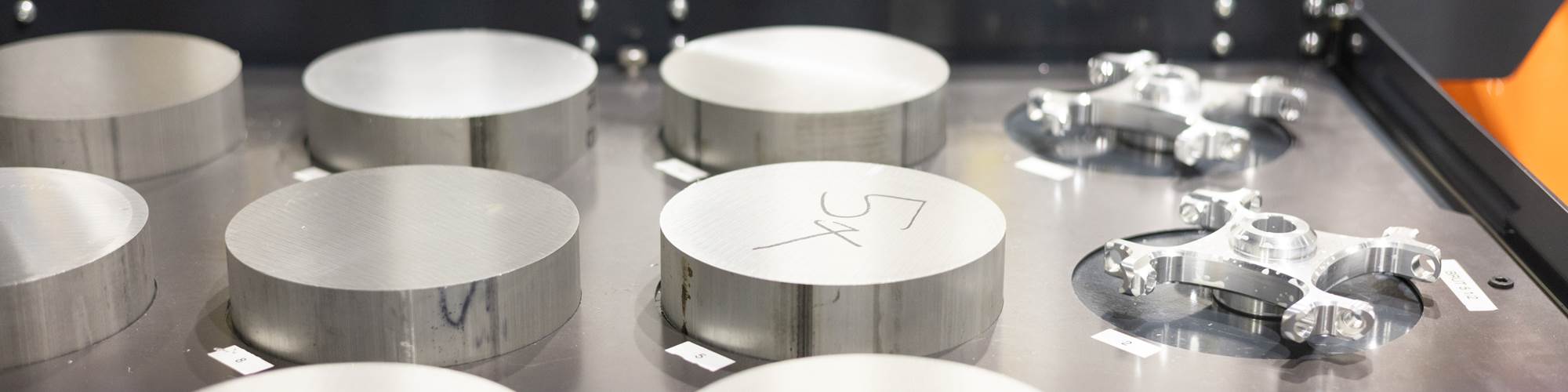

Précinov both makes stockpiles of parts for repeat customers and manufactures parts to order for customers in the opto-mechanics, robotics, medical, electronics and energy industries. This hybrid role has the shop working on lot sizes anywhere from a handful of parts to about 1,000 pieces, with tolerances regularly under 0.001 inch and cycle times between 10 and 15 minutes.

Keeping up with this demand is a challenge, so it began automating its machines in 2016. Out of a dozen machines, eight are now automated. Several of these are lathes with bar feeders, but its Matsuura four- and five-axis mills and Nakamura-Tome Super NTMX multitasking machine use something a bit more complex: PartNR automated cells from Waybo.

High-Mix Automation

Waybo’s PartNR cells each include one Kuka robot paired to one machine. This 1:1 setup ensures that an error in one robot or machine does not impact the overall machining operation, while also ensuring that machines are paired with robots of appropriate sizes.

Three cells use six-axis AGILUS robots, which have a 10-kg payload capacity and a 1,110-mm reach; one cell pairs a larger machine with a KR20 Cybertech robot with a 23.9-kg payload capacity and a 1,813-mm reach; and the last pairs another large machine with a KR22 Cybertech robot with a 27.3-kg payload capacity and 1,612-mm reach.

Précinov’s automated push has eliminated most secondary operations, but the shop has also combined some of these into its automated cells: one cell tasks a robot with polishing aluminum, while robots in other cells perform cleaning and washing operations.

Précinov uses these cells and robots to tackle jobs with long runtimes — and to combine operations in a single machine. Manipulator systems and adaptive grippers on the robots make this a relatively simple task: The robot picks raw material, flips the part after a first operation and removes it after a second operation, all on the same set of grippers.

In this way, the shop can machine multiple sides of a part without ever removing it from the machine tool. According to Mathieu DeBlois, Precinov’s owner, this setup often enables the shop to ship complete parts to customers without requiring secondary operations.

These adaptive grippers do use up part of the robots’ payload capacity — between 5 and 7.5 kg — but the flexibility and ease of setup enabled by this single-set solution make the cells well-suited to high-mix work.

Smooth Sailing

Before the PartNR cells arrived on its shop floor, Précinov sent several employees to practice programming and robotic manipulation with a Kuka training cell at Cégep de Lévis, a technical and pre-university school ten minutes away from the shop. These employees then made an in-house training guide that helped smooth the shop’s learning curve with the cells, simplifying adoption and initial implementation. The shop quickly set up its production process so that the longest part of job setups came from the CNC machine, not the robot.

The shop owes much of its swift programming to Autodesk’s FeatureCAM. After developing a postprocessor for the robots, programmers could extract values from the CAM model and push them to the robot. “At this time, maybe 80% of the job is done,” DeBlois says. “So you just need to perform some fine tuning on the path of the robot and then you’re done.”

With the part sizes, vises, fixtures and machine obstructions already programmed into the robot, this fine-tuning can take about an hour for a simple first-time part, extending to four or five hours for extremely complex parts. Once this first-time setup is complete, however, repeat jobs or similar parts come easily — especially if they are compatible with the AGILUS robots.

With these, the shop can essentially exchange programs between cells for simple setup. The similarities between robots in the PartNR cells and their programming also simplify Précinov’s training process, as training employees to operate one robot essentially trains them to operate all of them.

A specially designed system enables Précinov to run its PartNR systems with both pallet systems and individual pieces of raw material. This system has helped optimize the shop’s lights-out manufacturing, enabling it to double its productivity.

Instead of programming time, most of Précinov’s concerns about automating jobs revolve around chips, tool life and coolant. “When we’re running lights-out and a machine is stopped, I would say 99% of the time, the problem is somewhere inside the machine, not with the robot,” DeBlois says.

This certainty is bolstered by sensors in the grippers — if the machine drops a part, it knows the tension in the gripper is wrong and that the job must be delayed. Reaching this level of certainty for the machines’ operations is Précinov’s next big task, one the shop is already starting by assigning lasers to measure tools and ensure they are in good enough repair for lights-out machining.

To take advantage of lights-out machining, the shop handles difficult-to-automate jobs during its day shift and assigns simpler programs and those with estimated run times of more than eight hours to the cells’ queue during the lights-out second and third shifts. Completing these long-haul jobs overnight has been a major productivity booster for the shop, with lights-out capability freeing up enough capacity that the shop has been able to double its sales.

The shop has not needed to drastically increase staffing to manage this capacity, only adding five or six folks to its staff since automation began. DeBlois estimates that reaching the shop’s current level of productivity without automation would require 40 to 45 employees. Instead, the shop employs 25 people, with seven operators running keeping the shop’s 12 machining centers running 24/7.

Related Content

Parts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

Read MoreUsing Jaws as Grippers Enables Flexible, Low-Cost Automation

VersaBuilt’s automation systems significantly boosted Innovative Fabrication’s revenue. In return, the shop has helped VersaBuilt optimize its products.

Read MoreMedical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

Read MoreChuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreRead Next

Step Inside a Robot Shangri-La

While the Automate show in Detroit was not strictly geared toward CNC machining applications, the technology on display offered a glimpse into the future — and present — of robotic automation for the manufacturing industry at large.

Read MoreOEM Moves From Automation Implementation to Refinement

Automating challenging parts for full-weekend automation requires substantial process refinements that can significantly boost throughput.

Read MoreStandardization Leans the Way to High-Mix Automation

An increasingly digitalized, lean manufacturing process begins with a common selection of cutting tools and five-axis machining fixtures.

Read More

.jpg;maxWidth=300;quality=90)