Pay Attention to These 7 Themes at TASC

Looking to automate your shop floor? The Automated Shop Conference (TASC) will connect shops with experts who can advise them through this transition.

Share

Autodesk, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

As mentioned in a column earlier this year from Brent Donaldson, Top Shops data from recent years reveals that most high-performing small and medium-sized job shops utilize some form of automation. Shops not already automating will need to adopt some automation technology to continue competing with peers.

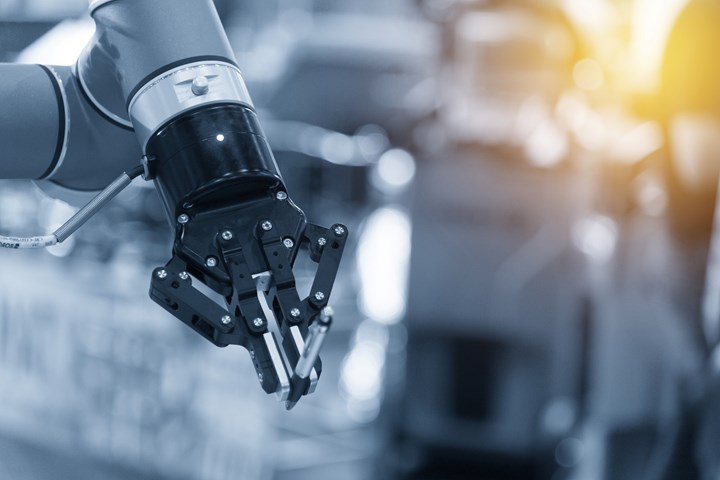

Machine shop automation is here — and necessary. But how do job shops join in this seismic shift?

TASC – The Automated Shop Conference aims to answer this question in Novi, Michigan, on Oct. 10 and 11. Attendees will find guidance on successfully developing and implementing a shopfloor automation strategy through seven key themes at the conference:

1. Automation Tech for Machining

Several presentations at TASC will emphasize the wide range of automation-capable technology on the market today. Many operations and applications can benefit from the surge in automation tech, and no companies will have the exact same needs for their automation.

2. Machining Process Automation

Investing in automation without a plan will lead to failure. Experts will introduce considerations for building successful automation strategies and ensuring the automation investments come out as a win.

3. Justifying Automation with ROI

An automated machining process will not look the same as a manual machine process. TASC attendees will learn how to redesign shopfloor processes to take advantage of technology and achieve high ROI from automated technology.

4. Robots, Labor & Technology

Shops across the world have demonstrated that automation and staffed operations can work together as a complementary whole. Attendees will learn strategies for meeting labor shortages and improving the job satisfaction of existing employees through implementing robotics and other automated technology.

5. Solving for Automation Talent

Automation is technology like any other, requiring skilled teams to leverage it to its fullest. Speakers at TASC will advise on how to train existing teams to use robots and other advanced manufacturing technology, as well as how to find new talent at home with automation.

6. Cobots & Machining

Cobots (or, collaborative robots) are a particular type of automated technology that are particularly useful for small and medium-sized shops. Experts will discuss how these robots can form the backbone of a job shop’s automation strategy.

7. You Aren’t Alone

TASC will bring together a community of peers at various points on the path of automation. Attendees will be able to network and learn more about what they need to succeed — and on Oct. 9, early attendees to the show will have the opportunity to see examples of automation and talent programs during tours of FANUC America and LIFT.

Related Content

-

Translating a Prototyping Mindset to Production

The experimental mindset that benefited BDE Manufacturing Technologies as a prototype job shop has given it an adaptable edge as a production facility.

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

-

Same Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.