From Process Monitoring to Quality Prediction Software

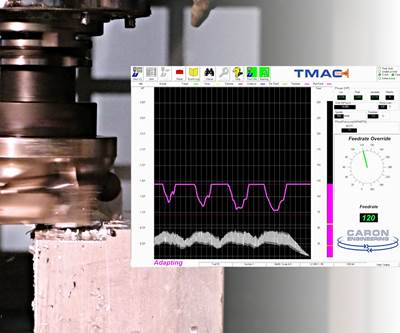

Even before inspection, Datanomix and Caron Engineering’s TMAC AI can extrapolate part quality from cut information. This information also helps shops push their tool life to its limits.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

“Production monitoring, at its core, is about the collection of data,” says Greg McHale, founder and CEO of Datanomix. Turning this raw data into actionable insights is a key part of modern machine shop software. The latest generation of software can even analyze this data and predict production outcomes in real time. One recent example of this kind of software program is TMAC AI, which was created as part of a partnership between Datanomix and Caron Engineering to collect tooling data, analyze it and form predictions to lower shops’ scrap rate and boost their tool life.

Real-Time Prediction

TMAC AI relies on data captured through Caron Engineering’s TMAC (Tool Monitoring Adaptive Control) system. Datanomix’s software system analyzes data about cuts from the TMAC sensors in real time, pairing them with a machine-learning model that predicts whether parts are in tolerance or out of tolerance, without waiting for inspection. From here, the system examines the data about whether parts meet tolerance to predict effective tool life, enabling users to push their tool life limits as far as they can while still creating a successful part.

The two companies first conceived of their current partnership just after IMTS 2022, planning to work hand-in-hand to bring advanced analytics to the common issues Caron’s customer base experiences. McHale says the software does this by automating the minimization of error (whether operator, tooling or even programming) and collection of tribal knowledge, ultimately improving tool life and reducing downstream issues that would be only discovered during inspection. He calls TMAC AI a way to “augment highly-skilled labor,” pointing to how the real-time predictions and notifications about process deviations act as faster substitutes for the data gathering that would go on during a lengthy process study. By automating these process studies, he says, skilled machinists can make decisions about process revisions faster.

Datanomix’s TMAC AI marks the boundaries for acceptable tool quality in blue, with a gold line indicating the average tool and a red line indicating the actual performance. Image courtesy of Datanomix.

The companies say that the software can build its initial model after 50 to 100 pieces recorded in TMAC. This can mean 50 to 100 pieces after TMAC and TMAC AI are installed together, or that the software can pull from the last 50 to 100 pieces recorded within TMAC if the AI add-on is installed later.

From the initial model, the software is usually able to judge whether parts are within tolerance with over 95% accuracy. McHale does acknowledge that some of this success can be attributed to the proven production pipelines of the OEM testers, with bad parts tending to exhibit “pretty significant physical noise” or other noticeable characteristics during machining, but says that refining this initial model is simple. When the model makes any errors, engineers can review the data and manually specify whether a part was conforming or non-conforming. The model updates with this data, further enhancing its accuracy.

Rob Caron, founder and president of Caron Engineering, predicts that this sort of software will become increasingly useful as robotics becomes more common across machine shop floors. With machinists spread across more machines, he continues, software powered by machine learning will be able to account for the everyday issues that machinists handle in a process, setting off an alert or finding other ways to automatically compensate and continue smooth production.

Repeat Performance

With the initial batch of data necessary for a model consisting of between 50 and 100 pieces, Datanomix and Caron Engineering recommend TMAC AI primarily to high-volume shops, but they can also see significant use cases for high-mix, low-volume shops’ critical repeat parts. While this software should work for any machine equipped with TMAC, Rob Caron notes that Swiss machining is a particularly good fit for the software.

Datanomix and Caron Engineering displayed the software at IMTS 2024 and are continuing to refine it with select customers through the end of 2024, with general availability in early 2025. Caron says that the software will not necessarily require Datanomix’s main software, as it will be an add-on to TMAC available through either company.

Related Content

Manufacturer, Integrator, Software Developer: Wolfram Manufacturing is a Triple Threat

Wolfram Manufacturing showcased its new facility, which houses its machine shop along with space for its work as a provider of its own machine monitoring software and as an integrator for Caron Engineering.

Read MoreDiving Deeper Into Machine Monitoring Data

Data visualization is the first step in using machine monitoring data, but taking it to the next level requires looking for trends within the data.

Read More5 Stages of a Closed-Loop CNC Machining Cell

Controlling variability in a closed-loop manufacturing process requires inspection data collected before, during and immediately after machining — and a means to act on that data in real time. Here’s one system that accomplishes this.

Read MoreProcess Control — Leveraging Machine Shop Connectivity in Real Time

Renishaw Central, the company’s new end-to-end process control software, offers a new methodology for producing families of parts through actionable data.

Read MoreRead Next

Machine Monitoring Spurs Shop's Meteoric Growth

EPTAM Precision Plastics has achieved multiple years of 15% YoY growth by effectively applying Datanomix’s benchmarking and machine monitoring features.

Read MoreMachine Monitoring Has a Lot to Learn

Supplementing CNC connections with sensors and machine learning enables predicting performance on the level of the individual part.

Read MoreFor Titanium, Tool Monitoring Smooths Low-rpm Cuts

Caron Engineering’s TMAC MP has been putting tool monitoring to work for years, but its “sawtooth algorithm” now meets a specific challenge in airplane engine machining.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)