CGTech's OptiPath and Force Modules Prove Complementary

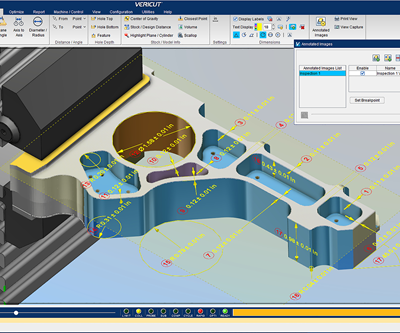

The OptiPath and Force modules of CGTech’s Vericut software have improved programming and cycle times at Ultra Machining Company.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Since implementing Force optimization, UMC has seen cycle time improvements ranging from 3 to 28%, achieving a return on investment several times over in the first year of use.

Three years ago, Vericut software developer CGTech spoke to programmers Don Lahr and Mike Triplett from aerospace and medical job shop Ultra Machining Company (UMC) about their use of Vericut’s OptiPath knowledge-based machining module. The men had recently installed an update that included a customization they’d asked CGTech to make on their behalf.

The enhancement request — Vericut SCR #16986 — simplified feed-rate changes through operator-accessible macro variables, streamlined setups and eliminated the need to involve the programming office for a simple variable adjustment.

Lahr and Triplett are still at UMC today, as is Cory Mahn, a 12-year employee who joined the programming department shortly after the customization update. At that time, there’d been some discussion of CGTech’s newly released Force module, a physics-based toolpath optimization tool said to reduce cycle times by 25% or more, but UMC did not have imminent plans for implementation.

UMC, an aerospace and medical job shop in Monticello, Minnesota, is home to dozens of modern CNC machine tools. The company has used Vericut from CGTech for more than 15 years.

Those plans changed in February 2020, as the company undertook its first Force test run on a fairly long-running job. “We cut around 10% off the cycle time on that one part number, which ended up saving the company almost $13,000,” Lahr says. The results were impressive enough that upper management agreed to invest in the software. “It’s not as large a savings as those that we’ve since achieved with Force, but it definitely opened some eyes to the value in moving forward.”

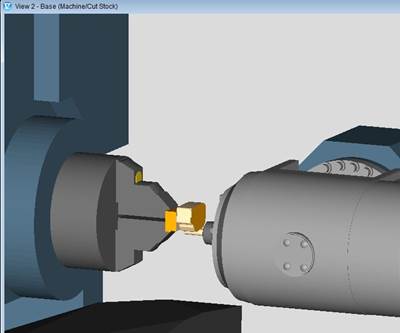

The workpiece in question is a medical component made of 304L stainless steel measuring approximately 2 × 3 × 0.5 inch. The largest tool UMC used is a 0.75-inch, four-flute carbide end mill, the smallest just 1/32 inch, taking axial depths of cut at 0.001 or 0.002 inch per pass. Lahr notes that Force provided the most benefit during roughing and semi-finishing operations, but he adds that even with very small tools such as those described above, it helped optimize tool paths to the point that cutter breakage fell to zero while cycle time often improved. “There’s definitely a benefit for tool life as well,” he adds.

Site Updates and an Automation Push

Recent changes at UMC also influenced the company’s decision to begin using Force. The company is still on its second generation of family ownership, but the number of employees has doubled to nearly 200 people. The number of CNC machine tools has also increased. There’s now a handful of Okuma M460V-5AX five-axis vertical machining centers, a pair of Okuma four-axis MB-46VAE vertical machining centers and three Matsuura MX-520 five-axis machining centers — two with four-station pallet pools.

Due to the skilled labor shortage, UMC and other job shops find that automated machine tending grows more important with each passing year.

Despite the higher headcount, shopfloor automation is on the rise. “It’s hard to find skilled workers, so we’ve been adding robots to some of our lathes and mills,” Mahn says. “This provides an opportunity to run lightly attended or even unattended in some cases, even though our lot sizes are fairly small. We’ve also upgraded our workholding on some of the machines, and are doing offline tool presetting.”

Comparing OptiPath and Force

As of this writing, the company has optimized 20 different part numbers with Force. Thus far, the cycle time improvements have ranged from 3 to 28%, but Lahr is quick to point out that UMC will recoup its investment three or four times over within the first year.

Those familiar with toolpath optimization might be wondering: If UMC was already using OptiPath, why would it invest in Force? After all, both products promise shorter cycle times and improved tool life, and both solve problems with cutter deflection, chatter in corners and similarly undesirable machining events. Does this mean UMC’s investment in OptiPath was a waste of money? Not at all, Gene Granata, CGTech’s product manager for Vericut, explains.

Each module complements the other.

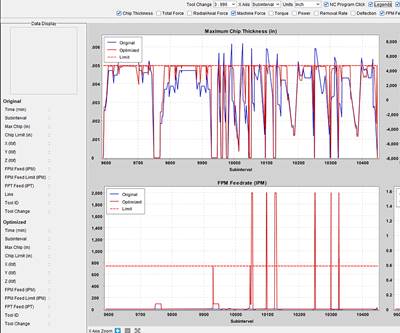

“Force and OptiPath are different products that use different approaches to optimization, but each one complements the other,” he says. “OptiPath, for example, doesn’t do any measurement of cutting forces. Instead, it uses either a volumetric method of optimization or one that measures chip thickness. Force also measures chip thickness but has additional checks and balances, including monitoring cutting forces or spindle power, and predicts tool deflection. In either case, material removal is kept constant by adjusting the feed rate and subdividing toolpath motions as needed to maintain consistent near-ideal machining conditions for each tool.”

Different Tools for Different Situations

Ultimately, both pieces of software have their own optimal use cases. Granata suggests using Force in hard, difficult-to-machine materials, where slight, instantaneous spikes in tool loads can spell big problems with cutters and machine spindles. On the other hand, he recommends OptiPath for soft metals like aluminum, mild steel and gray cast iron where the primary goal is to clear material as fast as possible (rather than keep a constant chip load), or for situations in which the tool’s cutting conditions never approach unsafe cutting force or spindle power levels.

According to Granata, many OptiPath customers continue using their tried-and-true OptiPath strategies when they begin using Force optimization, especially with harder or difficult-to-machine materials, and use OptiPath when cutting with certain tools that favor this optimization method. That said, he emphasizes there is no one-size-fits-all approach to programming.

“It depends on the strategies users prefer," he says. “If you’re an OptiPath power user, you probably would be more apt to add Force optimization to your OptiPath license and invoke both. You’re then able to choose, on a tool-by-tool basis, which to use. Programmers can even change strategies during a tool path to achieve the most effective optimization. The two are complementary toward offering the most possible optimization strategies.”

“Perhaps the biggest adjustment for me has been to let Force do its thing.”

The experiences of UMC’s programming team appear to support this theory. Mahn notes that Force has further decreased cycle time an average of 5 to 6% on jobs the team previously ran through OptiPath. As a side benefit, Mahn and Lahr have also found that Force reduces their overall programming time. “With Force, we don’t need to be quite as exact with toolpath creation in our CAM software,” Lahr says. “Perhaps the biggest adjustment for me has been to let Force do its thing. It will often suggest a feed rate that is at least double what I would have used, but if you just let it go, Force does it right.”

Related Content

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreRead Next

CGTech's Vericut 9.1 Improves CNC Simulation Visibility Options

Version 9.1 of CGTech’s Vericut includes enhancements to toolpath optimization, additive manufacturing, tooling and multi-tool stations, and measuring and inspection.

Read MoreAerospace Shop Adopts NC Optimization as a Means of Continuous Improvement

Steelville Manufacturing adopted CGTech’s Vericut NC verification software to safeguard its high-volume/high-mix work, but found unexpected benefits from its Force Optimization module.

Read MoreShop's Coding Solution Results in New Time-Saving Software Feature

For Ultra Machining Co., manually altering Vericut’s optimized tool paths at the machine was time-consuming and risky to the part. A custom macro alleviating this is now a feature of the software.

Read More

.jpg;maxWidth=300;quality=90)