4 Lessons Your Shop Will Take Away From TASC

The Automated Shop Conference (TASC) will give shops of all sizes and production volumes key insights and practical guidance on how to implement automation.

Share

ECi Software Solutions, Inc.

Featured Content

View More.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

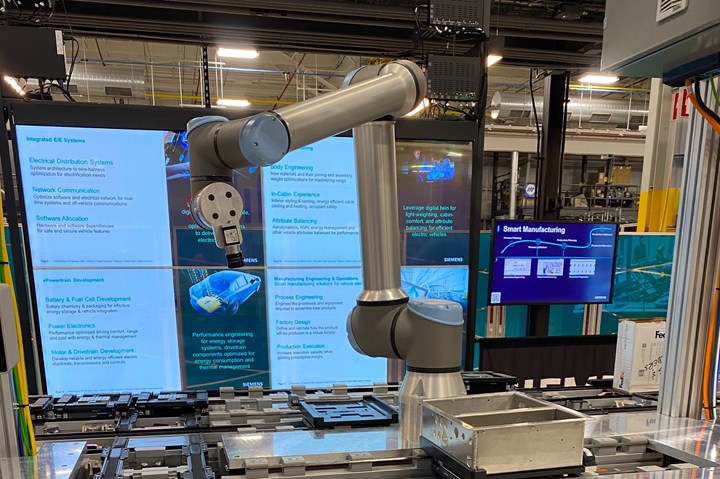

This cobot is part of Siemens’ Smart Factory Showcase at LIFT in Detroit, which attendees at TASC will have the chance to visit.

Shops are increasingly interested in automation as a solution to labor shortages or as a way to increase revenue through lights-out machining. But between choosing from the vast number of options on the market, the investment required and the potential effects on the workforce, taking the leap into automation can be intimidating.

The Automated Shop Conference (TASC) is a new event designed to help job shops make their first steps into automation. Throughout the two-day conference, which takes place Oct. 10 and 11 in Novi, Michigan, shops of all sizes will learn key insights and practical guidance for implementing automation. Here are some takeaways attendees can expect:

1. Automation is for job shops.

Automation isn’t just for high-volume manufacturing anymore. With the availability of flexible, inexpensive and easy-to-implement automation solutions such as collaborative robots (cobots), shops of all sizes and production volumes can automate. TASC has four full sessions dedicated to the topic of cobots.

2. Automation isn’t just for machine tending.

Machine tending is a major application for automation on the shop floor (and will be covered during a session titled “From Manual to Automated: Developing a Low-Cost Machine Tending System for Independent Machine Shops” by Mike Becker of Harland Sharp), but in sessions such as “Automated Inspections with Cobots” by Fabian Schmahl of Bold Promises Delivered, “Smart Technology Systems: Automating Each Step of the Manufacturing Process” by Rob Caron of Caron Engineering and “Automated Digital Inspection” by Craig Mathews from ThyssenKrupp Bilstein of America, TASC will also show how automation can help in other potential bottlenecks in the manufacturing process.

3. Automation doesn’t take away jobs.

Fears of automation taking away jobs used to be prevalent. But the manufacturing industry is starting to understand that it can help create jobs, and, as attendees will learn during Robby Komijenovic of Acieta’s session, “Robots: Your Key to Employee Retention,” it could even be key to keeping the employees you already have.

4. Automation isn’t just a technology change — it’s a culture change too.

Automation is a major change for a business, and in order to ensure success, leadership needs to get everyone involved on board. Matt Kirchner, president of LAB Midwest and TASC programming co-chair, will walk attendees through this process during “Culture Changeover – Preparing Your Team for Automation.”

Learn more about TASC, view the entire agenda and register at tascevent.com.

Related Content

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

-

Using the Toolchanger to Automate Production

Taking advantage of a feature that’s already on the machine tool, Lang’s Haubex system uses the toolchanger to move and store parts, making it an easy-to-use and cost-effective automation solution.

-

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)