The article Understanding MTConnect Agents and Adapters looks under the covers at how MTConnect, a manufacturing communication standard, helps shops use a digital, Web-based network to gather and analyze data generated by machine tools and other shopfloor equipment in real-time. But what about older machines and devices that generate little or no digital data on their own? Many shops would find it handy to get that old manual knee mill, band saw, coolant chiller or legacy CNC on, say, a shop-wide monitoring system—if only to capture whether it was in cycle or not.

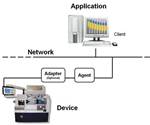

As the article mentions, one way to do this is to attach a “connection unit” designed to tap into the digital signals (inputs and outputs) existing on each factory device. Granted, the technology to capture these signals has been around for awhile, but the open language to communicate to them has not. The emergence of an open, network-based communications standard, such as MTConnect, is attracting renewed interest in the feasibility of networking “legacy” equipment.

Suppliers have responded to this opportunity with what I am calling internal or external solutions.

One example of the internal approach is from Memex Automation, a company that is an old hand at supplying manufacturing connectivity solutions. It offers electronic adapter boards that are installed inside a control cabinet. These solutions tap into the digital signals from existing input/output connection points. Once the hookup is complete, the internal processor can take the raw signals and further process, combine and name them with a remote software utility for use in machine monitoring or overall equipment effectiveness (OEE) applications.

Another example of the internal approach is the ORiON Machine Gateway Interface, from Nexas America, that provides machine connectivity, embedded DNC, a local file server and the MTConnect agent/adapter on one board. It supports various wired and wireless networking systems, plus it features dual serial ports to meet a range of automated machine communication and control needs. It also provides for barcode reader input, a feedback loop for adaptive control, and sensor interfacing.

An example of the external approach is from Real Time Development Corp., a longtime controls integrator. Its Quick Start Platform is mounted externally in its own bolt-on electrical enclosure, which houses an embedded PC, PLC and an I/O pickup. The software logic engine enables real-time control, sensing and MTConnect data processing. One option is to use a Hall Effect current sensor that simply clips on to the exterior of the machine tool’s power line. The system continuously measures power usage during cutting and can tell when the machine is idling, in cycle, experiencing tool wear and so on. The resulting data and sensor values are then available for the firm’s engineering and management (OEE) software and other MTConnect applications.

Two points are clear here: MTConnect makes the benefits of connectivity available to shops relying on legacy machines; and having enhanced connectivity available for legacy machines protects and extends their value as production assets.

Related Content

-

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

-

When this machine shop lost 90% of its business within three months, a reinvention was in order. Here's how it survived after quickly falling on hard times.

-

Data visualization is the first step in using machine monitoring data, but taking it to the next level requires looking for trends within the data.