Measuring for Flatness, Thickness and Parallelism

Using a simple surface plate makes a variety of gaging setups possible on one piece of equipment.

Surface plates provide a broad, smooth, flat reference surface that can be extremely useful for inspecting incoming, in-process or finished parts. When used in combination with various gages and accessories such as height gages, gage blocks, angle plates and squares, they can check a wide range of parameters, including length, flatness, squareness, straightness, angle, feature location and runout. Surface plates are simple and extremely versatile.

Surface plates provide a stable reference surface on a large scale, making many gaging setups possible on a single, simple piece of equipment. When a gaging application does not warrant the purchase of a special-purpose fixture gage, surface plates often provide an economical all-purpose solution.

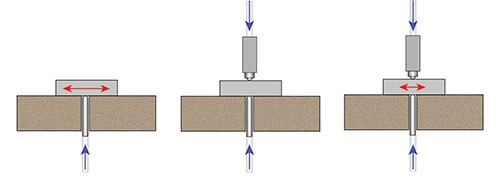

The surface plate itself also can be a gage. With a hole bored in the plate, a gage head or air jet can be installed to inspect flush surfaces for flatness without the use of a height stand. When small parts are involved, inspection is done by simply moving a part over the probe and reading the flatness variations directly on the amplifier readout. What is happening here is that the three highest points on the surface plate are creating a plane on which the part rides. The probe mounted in the plate then senses the change or variation in the surface of the part as it is moved over it. This is a dynamic check in that the part has to move in order to determine the out-of-flatness condition.

Of course an assumption has to be made with this form of flatness check. Note that in this example there is one air jet or electronic probe, and that the part is moved over it. Thus, there is no way that every square millimeter of the part could ever be explored. What generally happens is that the operator will follow a pattern on the part covering its outer and inner area. He then “assumes” everything in between is within what was measured. That is usually the case, but some areas might be missed. Nevertheless, for a fast and high-performance check, this type of flatness gage can’t be beat.

Speaking of high performance—and again this is a relative term—surface plates are available in many grades, and, therefore, the grade will help determine the performance of the system. Three-point support provided on a surface plate may have an accuracy to 50 microinches (inspection grade A). Other plate sizes and accuracies are available. This has to be considered as part of the measurement’s potential error.

If desired, a second gage head in a height stand can be positioned directly above the one embedded in the surface plate, enabling independent measurements of flatness, thickness and parallelism. But again, these checks can only be made in a dynamic state where the part is moved between the probes and explored for these conditions. With so many things going on and the need to share probes, it becomes a little more complicated for the operator.

With the simple, single-probe flatness gage, watching one readout for flatness variation and remembering the minimum/maximum is not that challenging. However, even in this application, a dynamic function on the amplifier could be employed to remember these points in the background and provide the difference, which would be the flatness deviation.

With two probes and the need for each to work independently and together at the same time, a smart amplifier with multiple inputs can be employed to make this easier for the operator. With a single swipe of the part, the smart amplifier could provide the flatness, thickness and parallelism easily and automatically.

As you can see, whether used alone or in combination with a variety of gages and accessories, surface plates offer smooth, flat reference surfaces for conducting a wide range of part measurements.

Read Next

Increasing Productivity with Digitalization and AI

Job shops are implementing automation and digitalization into workflows to eliminate set up time and increase repeatability in production.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreInside Machineosaurus: Unique Job Shop with Dinosaur-Named CNC Machines, Four-Day Workweek & High-Precision Machining

Take a tour of Machineosaurus, a Massachusetts machine shop where every CNC machine is named after a dinosaur!

Read More