How to Evaluate Prospective Employees

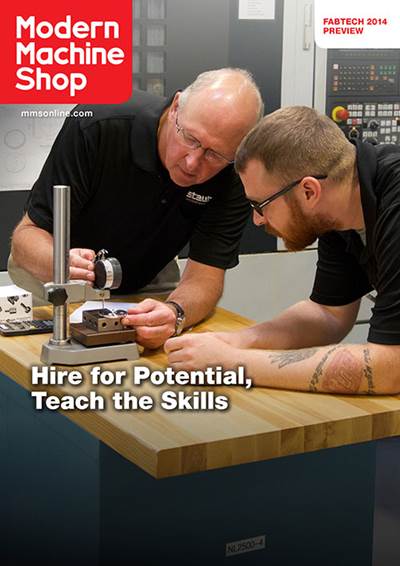

The consultant who has worked with Staub Machine describes his method for helping this shop identify candidates who have the personal attributes the shop is now seeking.

An unnamed figure in our recent article describing Staub Machine’s changes in hiring philosophy is Patrick Crotty. The founder of PXC Associates in Orchard Park, New York, Mr. Crotty is the management and hiring consultant who works with Staub Machine to screen and evaluate potential machining employees for their fitness with shop owner Tony Staub’s desire for employees who are strong in communications ability, adaptability and the capacity to learn. In the article I wrote, I merely mentioned that a consultant is involved. But I recently reached out to speak with him, after a reader of the article asked for more information about this aspect of Staub Machine’s hiring process.

And Mr. Crotty says hiring is just that: a process. At least, it ought to be seen that way. He works with various manufacturing companies on their hiring, and he says the disciplined process mindset to hiring is a big part of what he aims to convey to them. Employers often come to him because they have a job opening and they have one candidate they like for the job. They ask Mr. Crotty simply to evaluate the choice. This is an inefficient way to proceed, he says.

Instead, any job opening ought to be analyzed at least as critically as any other component of production that is about to change. For example, he asks: “What is the objective of this particular job position? What is the organization like around that position? Does the company wish to replace the person who left in terms of a one-to-one swap, or does the change provide the chance to change other job positions as well?” And then, most critically of all: “What are the criteria for being successful in this job?”

Mr. Crotty has been working with Staub Machine long enough to see this company’s success criteria change. President and owner Tony Staub came to realize that he should not necessarily look for machining experience as the primary consideration, because certain personal attributes were more vital to success than manufacturing skills. The skills could be learned.

In fact, there would always be learning. “Tony said to me at one point, ‘The stuff I’m doing today, I won’t be doing five years from now,’” Mr. Crotty recalls. It followed that the capacity to learn was more important than what the candidate already knew. However, a capacity such as this does not appear on a résumé, so how does the employer find it and evaluate it?

The interview is the answer, says Mr. Crotty. He happens to love employee candidate interviews. That’s important, because the interview is crucial to the hiring process. However, this interest also separates him from most hiring managers, who tend to dislike interviewing and have insufficient experience at it. As a result of discomfort and inexperience combined, the hiring manager in an interview often ends up doing the majority of the talking, so the prospect departs having revealed very little.

Mr. Crotty reverses the pattern. The candidate should do 70 to 80 percent of the talking, he says.

He screens candidates with an initial phone call before bringing them in, confirming that their basic expectations about the job (wages, for example) are in line with the position. Then, he invites the employer—Mr. Staub or a manager he delegates—to join him for the interview with the candidate. During this conversation, he says even so-called “soft skills” of the sort that Staub Machine is now seeking can be identified.

In the interview, an important point to make clear is that the candidate will have the chance to ask questions at the end, he says. The candidate permitted to ask questions early will ask something like, “Tell me about the job.” He or she will then be able to shape responses to parrot whatever job requirements have been revealed. The candidate should not be pre-armed in this way.

To get at those success factors most relevant to the job within the course of this interview, Mr. Crotty asks for detailed stories about the candidate’s past work. “The best predictor of future performance is the candidate’s performance in the past,” he says.

Résumé listings and initial responses to questions are generally sparse on detail, so he repeatedly asks for elaboration and further specifics, inviting candidates to describe in increasingly greater detail how they confronted, thought about, and handled the work-related challenges and opportunities they faced. He takes careful notes of these responses, as a way to focus his own attention and keep control of the conversation, as well as to document instances where success criteria are evident for comparison with the evidence revealed by other candidates.

When the candidate is finally invited to ask questions, he says, this invitation becomes a question in itself. The candidate reveals some of his priorities and potential in the points of curiosity he sees and the questions he is able to frame.

Written psychological assessments are also used, but these assessment tools are not enough to determine whether a person is the right fit. What they do provide are additional clues, particularly over time. On one assessment type, for example, “action oriented” was initially identified as a desirable characteristic for Staub Machine employees. Over time, however, candidates scoring low in this area actually proved more successful. Rather than someone inclined to spring to action in response to a problem, it seemed that a more contemplative type is more productive in the shop. Again, hiring is a process, says Mr. Crotty—and that process ought to produce metrics that can be used to improve effectiveness over time.

The process doesn’t stop when the employee is hired, he says. The assumption that it does is another error that employers make. Instead, orientation should be seen as a continuation of the hiring process, and it too should be done in a methodical way. Mr. Staub makes clear to his new employees that beginning the job means beginning a steady and planned training process that will take some time to complete. That is, he makes it clear to the employee (and to the organization around this person) that a new hire is expected to learn and grow, rather than being expected to perform well from the outset.

Done right, this orientation phase also should provide metrics that can be used to track and refine the process. In fact, the metrics here are fairly easy to capture and document. For example, what is the retention rate of the orientation period? What is the average amount of time needed to bring a new employee to full proficiency? And through careful process changes, can these measures be improved?

Related Content

The Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read MoreSolve Worker Shortages With ACE Workforce Development

The America’s Cutting Edge (ACE) program is addressing the current shortage in trained and available workers by offering no-cost online and in-person training opportunities in CNC machining and metrology.

Read MoreIn Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

Read MoreAddressing the Manufacturing Labor Shortage Needs to Start Here

Student-run businesses focused on technical training for the trades are taking root across the U.S. Can we — should we — leverage their regional successes into a nationwide platform?

Read MoreRead Next

Strengths First, Skills Later

The best indicators of a manufacturing employee’s success might be attributes that don’t appear on a résumé.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreInside Machineosaurus: Unique Job Shop with Dinosaur-Named CNC Machines, Four-Day Workweek & High-Precision Machining

Take a tour of Machineosaurus, a Massachusetts machine shop where every CNC machine is named after a dinosaur!

Read More

.jpg;maxWidth=300;quality=90)