World’s First Machine Tool Robot Made from Carbon Fiber

Lockheed Martin-Injaz-Tecgrant, cooperating with Airbus and Boeing, has developed the fast, accurate, portable XMini for automated aerospace manufacturing.

Share

Autodesk, Inc.

Featured Content

View More.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

Exechon is a joint-venture company comprising Injaz National, Lockheed Martin and Tecgrant AB (previously Exechon AB in Sollentuna, Sweden) that has introduced its new XMini robotic, five-axis machine tool aimed to produce a paradigm shift in automated aerospace manufacturing.

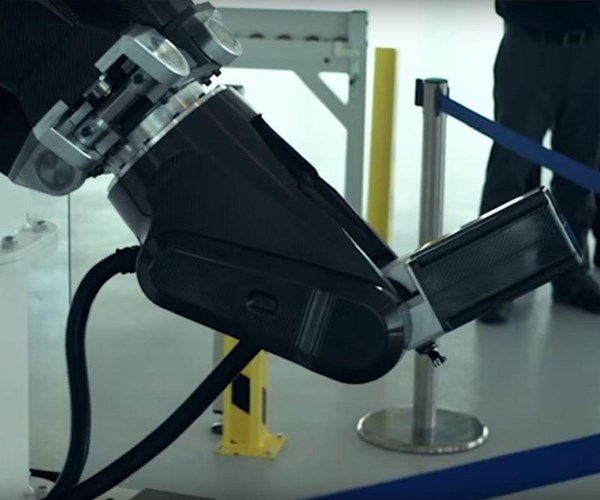

Demonstrated at the International Defence Exposition and Conference (IDEX, Feb. 17-23, Abu Dhabi, United Arab Emirates), the XMini merges the flexibility and high dynamics of an articulated-arm robot with the stiffness and accuracy of a rigid machine tool. Made using carbon fiber-reinforced composites, the XMINI can be taken apart and reassembled inside spaces traditionally inaccessible to machines or people, such as an aircraft wing box.

Using Parallel Kinematics Machining (PKM) to support industrial automated manufacturing, XMINI can function as a stand-alone tool or be easily integrated into an existing production system. Watch it in action in this YouTube video.

Features include:

- high-speed/low-torque as well as low-speed/high-torque machining capability

- 7-kN tool force

- 3-G acceleration

- positioning accuracy of ±10 micron

The machine tool can also be taken apart in five modules, each manageable by one or two persons, and integrated into production by one person in 72 hours.

The XMini is the first product developed by the Exechon JV, which is establishing an engineering and manufacturing center for advancing this technology in the aerospace, defense and automotive sectors, as well as other industrial areas. The facility is set to open at the Masdar Institute of Science and Technology (Masdar City, Abu Dhabi) in 2017.

"Exechon is based in the UAE to nurture local innovation and accelerate the expansion of industrial automation and robotics manufacturing in the region," said Kalle Neumann, Exechon chief executive officer. "The XMini on display at IDEX is built locally in Abu Dhabi to support international aerospace, defense and automotive markets around the world."

Commenting on the partnership, Rick Edwards, executive vice president of Lockheed Martin Missiles and Fire Control, said, "We are excited to celebrate this milestone in the partnership with local experts to develop the XMini, which will enhance local manufacturing capabilities and create long-term economic benefits. The XMini reflects Lockheed Martin's commitment to supporting the UAE's goal of becoming the leading supplier of cutting-edge, automated manufacturing technology."

His Excellency Sultan Rashed Saeed Al Dhaheri, chairman of Injaz National, added, "Today marks an important step in our international collaboration to bring this new technology and manufacturing capacity into the UAE. We look forward to continuing our partnership to facilitate meaningful and lasting economic impact throughout the Emirates."

This article originally appeared on CompositesWorld.com.

Related Content

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

-

Translating a Prototyping Mindset to Production

The experimental mindset that benefited BDE Manufacturing Technologies as a prototype job shop has given it an adaptable edge as a production facility.

-

Four-Axis Horizontal Machining Doubles Shop’s Productivity

Horizontal four-axis machining enabled McKenzie CNC to cut operations and cycle times for its high-mix, high-repeat work — more than doubling its throughput.

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)