What Is Arbitrary Speed Threading?

This CNC function enables an operator to control chatter when repairing threads on components such as oilfield pipes.

Share

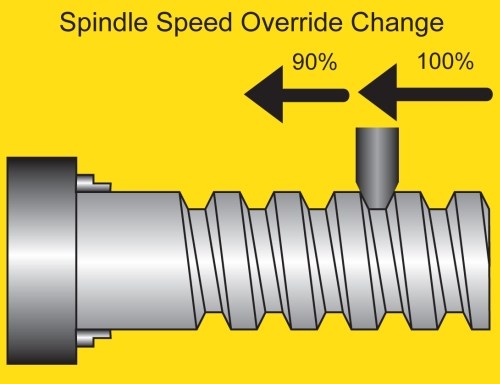

Arbitrary speed threading enables operators to use the spindle override function to minimize chatter during threading operations while maintaining the correct thread lead.

Arbitrary speed threading is a CNC function that enables a turning center operator to adjust the spindle speed during thread cutting to reduce chatter. It ensures that the cutting tool remains coordinated with the spindle speed at all times during threading to produce the programmed lead. Controls that don’t offer arbitrary speed threading do not allow an operator to change the spindle speed during threading because that would change the thread lead and possibly damage the part. This function is particularly helpful for thread repair of components such as oilfield pipes because chatter is more likely to occur with the small amounts of material that’s typically removed.

Arbitrary speed threading automates the rethreading process that used to be a highly skilled manual process. It also provides the functionality to pick up and repair an existing thread, making it easy to use and fast to set up and reproduce original threads. FANUC America now offers the arbitrary speed threading option on its 0i-TD and 0i Mate-TD CNCs for new turning centers. (When purchasing a new turning center, specify this option on the FANUC CNC to the machine tool builder or distributor.) The thread repairing process can be simplified further using the company’s Manual Guide i conversational programming, enabling operators to use straightforward graphical screens to answer simple questions to generate a suitable thread repair program. Therefore, knowledge of G-code programming isn’t necessary.

Related Content

-

2 Secondary Coordinate Systems You Should Know

Coordinate systems tell a CNC machine where to position the cutting tool during the program’s execution for any purpose that requires the cutting tool to move.

-

From Tradition to Transformation: Century-Old Manual Machine Shop Adds CNCs

After 122 years of working with manual mills and lathes, this fifth-generation shop acquired assets of a local CNC machining business and hired the owner. Here’s how it’s going a year later.

-

4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

.jpg;maxWidth=300;quality=90)