Broken-Up Programs Limit Broken Tools

Posting tool paths for different operations to the machine individually rather than as a single, combined part program helps this heavily lights-out operation quickly address the causes of tool wear and breakage.

Share

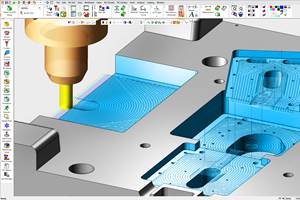

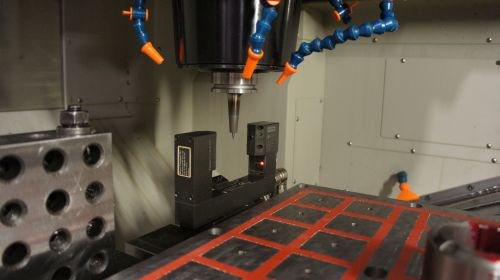

Breaking up programs by operation speeds the process of troubleshooting a worn or broken tool after an alarm is triggered by a Blum laser tool probe, an accessory common to all of the shop’s machining centers.

Thanks to workzone-mounted cameras and other remote machine monitoring and control technology, personnel at Hard Milling Solutions (HMS) can respond immediately to any problems during the shop’s two lights-out shifts. However, determining the source of the problem when a machine’s laser tool probe triggers an alarm for wear or breakage can still take a great deal of time. In these instances, the shop relies on another strategy to get spindles spinning again as quickly as possible, one that’s exceedingly simple to execute. That is, to segment part programs by posting tool paths for different operations separately, rather than as a package.

Even during the single, staffed shift, the shop floor at HMS can be a lonely place. Programmers like Ryan Mihelcich, shown here, rely on video feeds and automatic alerts to keep them apprised of ongoing machining operations while they program future jobs. In fact, one such alert is tied into the shop’s doorbell, which rings whenever a machine stops.

The essential idea is that determining why a one-hour program alarmed out is far easier than determining why a 10-hour program alarmed out, says Corey Greenwald, HMS founder and president. That’s because after an alarm, the program essentially “rewinds,” he explains. So, the process of discovering when a problem occurred (let alone why) requires retracing steps, sometimes all the way back to the first toolpath. Even if the 10-hour program calls for hourly checks for tool wear or breakage with an integrated laser probe, the only benefit of an alarm is ensuring that the machine shuts down and that the problem doesn’t get any worse. Posting the program in hourly segments instead, with a laser check after each, makes troubleshooting faster by isolating the portion of the machining routine where the error occurred.

In some cases, a simple visual check of the part might be enough to determine which operations completed before the alarm. However, HMS’s mostly mold and die industry work, which often involves taking multiple, light passes across the same complex geometry, makes these visual checks less reliable than they might sound, Mr. Greenwald says. “If you’re squeezing down into a tight crevice, it can be hard to see with the human eye whether you've got a 6-ball (6-mm ballnose end mill) or a 3-ball in there,” he explains. He adds that segmented programs come in particularly handy when multiple operations use the same cutting tool, particularly when those operations don’t occur in sequence. “With one big program that’s errored out, all you’ll know is which tool is in the spindle.”

Although this concept is straightforward, it might not work for every shop. HMS has standardized largely on Makino, which supplied seven of the shop’s eight high-speed, hard-milling VMCs. That builder’s Professional 5 CNC offers two capabilities that facilitate HMS’s segmented programming approach. One is the capability to customize program names. This helps employees understand what’s happening during a particular portion of the machining routine, and Mr. Greenwald says it comes in particularly handy when multiple, non-sequential operations employ the same cutter (examples of typical names for HMS program segments include “10-mm rough” and “6-mm semi-finish”). Perhaps more importantly, the CNC enables running multiple programs in sequence, and that list can be displayed in the DNC list. “You could write a macro to list the operations with other controls, but when it errors out, it’ll just rewind to the beginning. With the Pro 5, it’s easy to have a list of every program that’s going to run, and they’ll run one after the other. If there’s an alarm, the program segment where it occurred will show up as incomplete.”

Segmented programming certainly comes in handy, but this is a shop that thrives largely on ensuring tools don’t break or wear prematurely in the first place. For an operation focused so heavily on unattended machining, process reliability and predictability are paramount. Although far more involved than segmented programming, HMS’s approach to ensuring that reliability and predictability is rooted in very simple concepts. Essentially, the shop makes the most of its CAM software tool library by painstakingly tracking machining parameters for every job, then standardizing on the most effective settings for particular combinations of cutting tools and materials. This March-issue feature article tells that story.

Related Content

Cimatron's Updated CAD/CAM Software Streamlines Mold Design

Eastec 2023: Cimatron V16 includes a clean new user interface and increased automation for faster mold design, electrode creation and NC programming.

Read MoreGrob Systems Inc. to Host Tech Event With Industry Partners

The 5-Axis Live technology event will highlight new machining strategies for optimizing the production of complex medical, aerospace and mold/die parts.

Read MoreFor This Machine Shop, Licensing Is the Answer to the Inventor’s Dilemma

Machine shops are natural inventors, but not necessarily suited to supporting and marketing a product. This Minnesota shop with an invention related to micromolding will share it through licensing.

Read MoreIn Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

Read MoreRead Next

Inside Machineosaurus: Unique Job Shop with Dinosaur-Named CNC Machines, Four-Day Workweek & High-Precision Machining

Take a tour of Machineosaurus, a Massachusetts machine shop where every CNC machine is named after a dinosaur!

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreIMTS 2024: Trends & Takeaways From the Modern Machine Shop Editorial Team

The Modern Machine Shop editorial team highlights their takeaways from IMTS 2024 in a video recap.

Read More

.jpg;maxWidth=300;quality=90)