Why Oilfield Parts Producers Consider Retrofits

There are a number of reasons why shops serving the oilfield industry see value in upgrading existing machine tools with a new control package.

Share

These days, machine shops that serve the oilfield industry in areas such as Texas and Pennsylvania are going gangbusters. This has spurred a number of them to add capacity or improve their capabilities by purchasing new machines or retrofitting older equipment with a modern control package. If price were no concern, these shops would more than likely choose to buy new. However, the cyclical nature of this industry combined with the size of the equipment required to machine some oilfield components has a number of shops eyeing more affordable CNC retrofits.

Terry Ruppe is the owner of Arrow Controls in Houston, Texas, a company that specializes in machine repair and retrofitting, often using control packages from Centroid CNC (Howard, Pa.). Mr. Ruppe says there remain a number of 1980s-era machines in his area that are well-suited for control retrofits. Many of those machines are large, rigid units with heavy castings. These machines also are commonly geared so as to provide substantial axis torque, enabling them to take heavy cuts. This is especially advantageous for sizeable steel parts that require a lot of material removal, such as those used in the oilfield industry.

Mr. Ruppe recently hosted Centroid sales and marketing manager Keith McCulloch for visits with a number of Houston-area customers to learn more about their specific machining challenges and how they have become more competitive through retrofitting older equipment. The following highlights some of the feedback they received.

BENEFITTING FROM RETROFITTING

A retrofit differs from a machine rebuild and complete manufacture in that it typically upgrades only the CNC, axis drives and axis servomotors on an otherwise mechanically sound machine. A well-known advantage of retrofitting is its relative affordability. The cost to retrofit an older machine can be one-third to half of the price of a comparable new machine, Mr. McCulloch says, and the savings are often more significant for big equipment. He notes that this is particularly attractive to shops serving cyclical industries like oilfield, because they won’t have to cope with higher new-equipment payments when business conditions go south. They’re better-positioned to weather sales ebbs. Retrofitting also enables shops to use existing tooling and fixtures, whereas a new machine would likely require the purchase of different workholding devices. The expense for these new devices can be significant, especially for large machines. In addition, the machine is usually retrofitted onsite, so there are no rigging costs that otherwise would be incurred when installing a new machine. Plus, a shop can realize further savings by using a machine’s existing servomotors if they are in good shape and by upgrading to a new Centroid encoder and drive.

But retrofitting offers advantages beyond affordability. Here are a few:

• Reliable, user-friendly machine control. A CNC retrofit provides improved reliability and functionality compared to an older machine’s original control, and this is helpful in a number of ways. For example, a more intuitive control interface can help speed setups and minimize the chance for programming and/or setup mistakes, which could possibly damage or scrap a high-value workpiece. Similarly, shops are also more confident in quoting work for large, expensive parts knowing the new control won’t hiccup partway through an operation and cause the part to be damaged. Shops also are better-positioned to take in “hot” jobs that require fast turnaround due to the retrofitted machine’s improved reliability and more consistent performance.

A new CNC can also improve a machine’s capability to accommodate a wider range of work. Mr. Ruppe cites a customer that kept an older machine set up for only one sporadic job largely because the machine’s original control was unreliable and challenging to use. This machine would sit idle for months until the job returned, but by that time, the control typically wouldn’t work correctly and required service. Since being retrofitted, the machine is now used for that job and a variety of others because of its improved reliability and simpler programming.

Centroid retrofits for large machines commonly use the company’s PC-based M400 for mills and T400 for turning centers, which offer the Intercon conversational part programming software. Fill-in-the-blank conversational programming can enable shopfloor personnel to create more programs on their own, freeing a shop’s CAM programmer to focus on more complex jobs. In addition, because controls such as these have solid-state hard drives that provide much more storage capacity (a standard Centroid M400 CNC has a 120-GB hard drive), many programs can be stored in the control and called up whenever jobs repeat.

• DC to AC spindle motors. Older turning centers with DC spindle motors can be upgraded to new AC motors and drives during a control retrofit. In fact, the physical size of a modern AC motor is smaller than that of a DC motor having the same power rating. Therefore, it’s possible to replace a 30-hp DC motor, for example, with a 40-hp AC motor because the latter is essentially the same size as the original. This enables a shop to install a bigger chuck to turn larger parts instead of purchasing a more sizeable machine to accommodate that type of work.

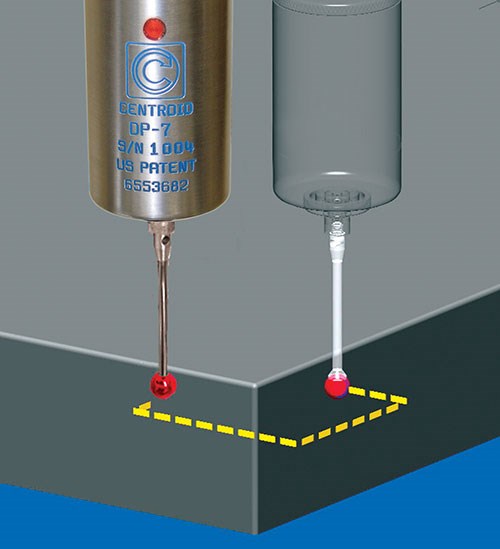

• On-machine probing. Similarly, new capabilities can be added to a machine during a control retrofit. One example is on-machine touch probing, which takes advantage of CNC features not available with older controls. Probing can be particularly valuable in speeding and simplifying setups for large parts, which are otherwise cumbersome to manually indicate on a table. The CNC uses the data from a probing routine to compare the actual positions of part or fixture features to their expected positions, and then compensate by shifting the program based on the actual positions. Probing routines can be used to automatically set part zero position and fixture offsets as well as locate edges, bore centers, boss centers and so on. Likewise, a tool measurement probe can be added to automatically set tool height or check for broken tools during stretches of unattended operation. Tool measurement probes from Centroid can set tool height to within 0.0001 inch.

• Adding axes. Another example of enhancing a machine’s capabilities during retrofit downtime is adding a fourth- or fifth-axis rotary table to a three-axis VMC. A rotary table can be used for true four- or five-axis contour machining or part positioning, which can reduce the number of setups required to completely machine a part and help ensure high feature-to-feature accuracy for complex work.

PRE-RETROFIT CHECKLIST

Upgrading to a new control package can breathe new life into dated machines. That said, those machines must still be in good mechanical condition. When evaluating a machine for a potential retrofit, Mr. McCulloch suggests examining the ways for signs of rust or wear. Look for evidence of previous improper lubrication and make sure all axes slide freely. Similarly, ensure that the ballscrews rotate smoothly and inspect the ballscrew races for pitting or scoring. Sometimes a ballscrew can be misidentified as the cause of rough axis motion. In most cases, though, a failing or faulty bearing is the cause of excessive backlash or rough axis movement during ballscrew rotation. Bearing replacement is much easier and less costly than ballscrew replacement.

In addition, check spindle motor operation and listen to the sound of the spindle bearings while the motor is running. (If the existing machine control is not operational, turn the spindle by hand or have a technician connect a smaller external spindle drive to slowly turn it.) Most faulty motors can be repaired or replaced at a reasonable cost. If the machine makes excessive noise while the motor runs, it is a good idea to have the spindle bearings replaced before the retrofit. This typically requires the machine’s head or spindle cartridge be removed and shipped to a spindle rebuilding shop. Cost for this can range from hundreds to thousands of dollars, depending on the machine.

Related Content

Tips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

Read MoreSelecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

Read MoreWhat are Harmonics in Milling?

Milling-force harmonics always exist. Understanding the source of milling harmonics and their relationship to vibration can help improve parameter selection.

Read MoreHow to Mitigate Risk in Your Manufacturing Process or Design

Use a Failure Mode and Effect Analysis (FMEA) form as a proactive way to evaluate a manufacturing process or design.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)