When Two Spindles Are Better Than One

Machining centers with multiple spindles offer a compromise between flexibility and productivity. Different machine designs use the multiple spindles in different ways.

Share

Takumi USA

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View MoreMachining centers have become faster, more accurate and less expensive over the years. The evolution has led to this common phenomenon in high-volume production: plants using banks of machining centers to make parts that might otherwise be produced using a hard-tooled transfer system.

The advantage is flexibility. A machining center can easily switch from running one part number to running a related part in the same family. A machining center is also easy to reconfigure for running a different job altogether. However, all of this flexibility imposes various costs, not the least of which is the overhead reflected in the amount of space that each machine takes up.

In fact, where many high-volume jobs are concerned, the design of the conventional machining center is simply too flexible. This is a machine adapted to handling the daily-changing part mix typical of a job shop. Facilities requiring more productivity and fewer changeovers than what a job shop requires could make good use of a machining center that was designed to be just a little more dedicated than this.

Enter the two-spindle machining center. In recent years, a variety of machine tool companies catering to high-volume applications have expanded their offerings to include machining centers that have two parallel spindles able to machine two identical workpieces at once.

The design is particularly appropriate to suppliers in the automotive industry. In a climate of increased outsourcing of machining work, some of these companies are now seeing machining volumes larger than what they are accustomed to running. But at the same time, these companies remain contractors—meaning they have to serve multiple customers at once, and they have to be ready to win new jobs and lose existing ones with little advanced warning. Their machine tool choices must reconcile flexibility, productivity and economy. For many of these applications, two-spindle machining centers come closest to striking the right balance.

In conversations with the providers of two-spindle machines about why their customers are buying them, one phrase comes up again and again: floor space. A two-spindle machine has the potential to deliver almost two times the productivity, within a footprint only slightly larger than that of a single-spindle machine. At least one major machining contractor that now prefers two-spindle machines made the switch to this design only when one of the company’s plants had hit the wall—literally—in its ability to house yet another single-spindle machine.

Shared Burdens

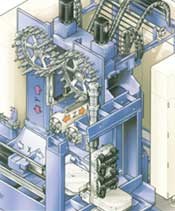

Liberty Precision Industries (Rochester, New York) is a supplier of two-spindle machines that has a history of providing in-line and rotary transfer systems, as well as independent CNC machines in cellular configurations. The company added its “Twin-Spindle” machining centers to this range of solutions a little more than 2 years ago. In fact, the company also offers a “Quad-Spindle” machining center with four spindles in a row. While the two-spindle machine has found applications machining steering knuckles and suspension components, for example, the four-spindle machine is potentially well-suited to parts that are smaller and lighter, such as valve bodies and alternator housings.

John Engels, director of business development for Liberty, offers more detail about the economic advantages of the multiple-spindle machines. These machines consolidate not only floor space, but also the number of operators required to meet a given production rate. They also reduce a shop’s maintenance burden, because the two spindles machining two workpieces (or four spindles machining four) share common fluid systems and other machine resources that would otherwise require separate maintenance on separate machine tools.The result of all of this consolidation is a lower cost per workpiece compared to conventional machines.

Accuracy Questions

One company that has attempted to quantify the economic advantage of using two spindles to machine in unison is Stama.

A machine tool builder owned by Chiron, Stama is represented in the United States by Chiron America (Charlotte, North Carolina). Machining centers with a twin-spindle design account for 60 percent of the machines this company sells, and its engineering experience with this design has served to refine the design of Chiron’s twin-spindle machines as well. Where Chiron offers smaller, faster machines that tend to machine die cast aluminum, Stama offers larger and heavier machines for iron and steel.

Stama provided the graphs on this page—based on research performed at Aachen University in Germany—that compare single- and twin-spindle machining centers for representative high-volume parts. They show that a twin-spindle machine cutting two workpieces at once does not exactly halve the share of machining time represented by each piece, but it does reduce it by a significant amount (42 percent, according to this comparison).

In terms of the cost per piece, the optimum case occurs when four pieces are clamped at once, so that each spindle machines two workpieces during the cycle. Here the cost per unit falls below 70 percent of that of running the same four-piece setup on single-spindle machines.

Chiron America senior vice president Hans Strey says that despite the cost advantages, various concerns prevent companies from choosing a twin-spindle solution. Many prefer that two spindles remain divided between two different machines as a sort of insurance policy, so there will still be 50 percent capacity available if one spindle goes down. Others, he says, worry about the possibility of error resulting from one spindle’s position drifting with respect to the other—perhaps because of thermal effects. But Mr. Strey says this worry need not apply to modern machines. In Stama’s case, the company uses finite element analysis to design around heat sources so that spindle positions remain constant relative to one another.

Mike Wanthal is an engineering manager for Chiron. “As a rule of thumb,” he says, “we tell customers they can use our twin spindles with confidence for any accuracy down to 75-micron true position under 1.67 Cpk conditions.”

For even tighter accuracy, he notes that there is still the option of leaving the tool out of one spindle while the other spindle briefly cuts alone. For example, a part with one very precise hole could be machined in the twin-spindle mode for every feature except that hole. The hole could be bored first with a tool in the left spindle, then with a tool in the right.

Mr. Wanthal says the tooling is the most likely potential source of error between the two spindles. Twin-spindle users need precision tool setting, and they also need high-end cutting tools for the sake of the dimensional consistency from tool to tool. However, facilities accustomed to machining precision parts in large volumes probably are already applying these disciplines to their single-spindle machines.

Two Spindles, One Workpiece

There is also an altogether different option for using two parallel spindles on a machining center—one that involves alternating cuts rather than simultaneous machining.

Instead of producing two identical pieces at once, a two-spindle machine might use both spindles to attack a single piece in the same cycle. Machines employing this strategy can still be thought of as twin-spindle machines, but because the spindles do different work, the twins are fraternal instead of identical. While one spindle is cutting, the other undergoes a tool change and prepares for the next cut. Thus the two-spindle, one-workpiece strategy reduces the impact of tool change time.

One company able to discuss the relative merits is Alfing Corp. (Plymouth, Michigan). The company supplies twin-spindle machines of both types. Its “Synchro” model cuts two workpieces simultaneously, while the “2-Spindles” model cuts with one spindle at a time. While the former machine has three shared axes, the latter machine moves each spindle along its own independent Y and Z, with only the X axis shared between them. This axis moves the workpiece back and forth between the two spindles.

On the Synchro machine (for cutting two pieces at once), Alfing offers independent adjustment of the two fixture positions. This feature can be used to compensate for differences in tool setting measurements between the two tools. It can also be used to compensate after a significant crash, if that crash results in spindle location differences.

Alfing sales manager Al Hutko says the number of tool changes suggests which type of two-spindle machine is more appropriate. A part with relatively long cutting times between infrequent tool changes is better suited to simultaneous machining of two workpieces at once. But a part with a large number of tool changes and a large amount of tool change time relative to the cutting time might be machined more productively at a rate of one workpiece per cycle—provided the out-of-cut time for tool changes can be reduced. A two-spindle machine cutting with alternating spindles accomplishes exactly this.

Toward Zero Toolchange

The “Mach 1” is a two-spindle machining center from Lamb Technicon (Chesterfield, Michigan) that can be used in both ways—either simultaneous machining to cut two pieces at once, or alternating use of the spindles to reduce the tool change time.

Sometimes both strategies are used on a single machine, so that different strategies can be applied to different part numbers. And sometimes both strategies are used in the same cycle, so that different approaches can be applied to different features of the part. The machine has been available for about 5 years, and today there are more than 300 installed.

The Mach 1 also has two Y axes, two Z axes and a shared X axis. When the two spindles are machining identical pieces in unison (Lamb calls this “stereo machining”), the spindles can employ separate tool offset values. One feature of the machine that makes it easy to switch as needed between simultaneous and alternating use of the spindles is a shared tool magazine. All of the tools loaded in this magazine can be accessed by either spindle throughout the cycle.

Bryan Graham is vice president of customer accounts for Lamb. The largest share of users who have migrated to this machine from some other high-volume solution have come from single-spindle machining centers, he says. The company generally provides process engineering support to help with this transition. “If you try to just move the fixtures and tooling over from the previous machining center, you won’t get the best use from this machine,” he says.

For example, when the two spindles are used in an alternating mode to reduce the impact of tool changes, the best productivity comes when the length of time that a given tool is in use is long enough that it can completely bury the amount of time required for the tool change going on concurrently. The goal is to approach a state of “zero tool change time” in which there are no moves related to changing tools that are not covered by some machining operation occurring at the same time. To accomplish this—given that the part may include various holes for which the machining time is very short—it may be necessary to use some high-density workholding design to let a single hole-making tool address many pieces, and remain in use longer.

Since this machine was introduced, the company has seen it move into unexpected applications. Perhaps the most significant of these, says Mr. Graham, is the gun drilling of oil channels in crankshafts. This work traditionally has been done on transfer lines. Now it can be done on a modified version of the company’s two-spindle machine that places the spindles in a vertical line instead of side by side. (See photo, above right.) Because this solution is programmable and therefore reconfigurable, it makes it much easier for independent suppliers to take on crankshaft machining.

Related Content

JTEKT Launches New Series of HMCs

The new FH5000 series machines include a 500-mm table capable of handling 1,000-kg loads.

Read MoreShop Replaces Two Verticals With One Horizontal

By trading two VMCs in to help finance the purchase of a new HMC, this shop was able to significantly increase production and move to lights-out machining.

Read MoreHorizontal High-Speed Machining Saves Hundreds of Work Hours

High-speed machining is the latest change at Blair-HSM South, helping this once old-fashioned shop improve productivity and morale while enabling new work.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreRead Next

Agile Or Lean?

Either way, machining centers may make sense. When CNC machines are used for high-volume work, this question comes first.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)