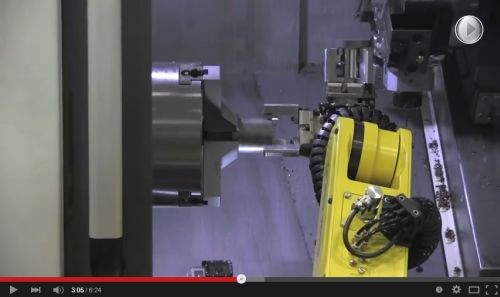

Video: Robot Flipping System for Turning

This video demonstrates how robot flipping station can serve the same purpose as a subspindle on a one-spindle multitasking center.

A lathe or multitasking center equipped with both a main spindle and subspindle enables turned parts to be machined on both ends in one setup, by simply passing the bar from one spindle to the other. But what if you don’t have a subspindle? A robot flipping system can be a cost-effective automated solution.

The video above from Methods Machine Tools shows a Nakamura AS-200 multitasking machine equipped with a FANUC LR Mate 200iD7L robotic arm with two sets of grippers. Around 3:06 in the video, the robot removes the first workpiece, swaps in a blank, then sets the first workpiece unmachined-side down on a shelf just to the left of the machine door. The robot then grasps the part from underneath, flipping it over to be placed back in the spindle for machining on the other end. The configuration enables a two-spindle process to be completed with just one spindle on a smaller machine.

Related Content

-

Building Machines and Apprenticeships In-House: 5-Axis Live

Universal machines were the main draw of Grob’s 5-Axis Live — though the company’s apprenticeship and support proved equally impressive.

-

Swiss-Type Control Uses CNC Data to Improve Efficiency

Advanced controls for Swiss-type CNC lathes uses machine data to prevent tool collisions, saving setup time and scrap costs.

-

WFL Milling Machines Feature Smart Sensors, Control System

M50 Millturn / 3,000 mm and M80X Millturn / 4,500 mm turning-boring-milling machines come equipped with a grinding attachment and a vibration-damped Silent ToolsTM Plus boring bar.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)