Pull Boring Highlights the Capability of Deep Hole Making

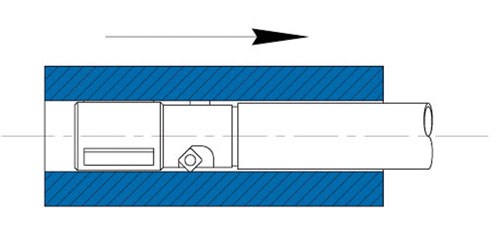

Pull boring enables users to achieve remarkable straightness in deep holes. A variation of this technique is also effective when maintaining consistent wall thickness (in long, cast pipes, for example) is top priority.

Share

Because the ability to make deep holes effectively and efficiently is critical in many applications, deep hole technology is one of the most highly developed sectors in metalworking. It covers a diverse range of processes and methodologies. Unisig (Menomonee Falls, Wisconsin), a supplier of machines, tools and automation for deep hole making, says the list of industries it serves includes aerospace, automotive, defense, hydraulics, mold making, oilfield and energy. Yet deep hole making is largely the domain of shops specializing in this capability, whereas technology suppliers such as Unisig believe that a wider awareness of deep hole making processes would alert new users to valuable opportunities.

Related Content

Darex Adds End Mill Attachment to Drill Sharpener

This LEX600 end mill attachment enables users to sharpen the primary and secondary grind on the tips of two-, three- or four-fluted end mills up to 5/8".

Read MoreEmuge-Franken's New Drill Geometry Optimizes Chipbreaking

PunchDrill features patent-pending geometry with a chipbreaker that produces short chips to control machining forces.

Read MoreMeasuring Torque, Thrust Force for Smart Drilling Operations

To monitor drilling operations for smart manufacturing solutions, torque and thrust force can be measured.

Read MoreTungaloy Drills, Milling Inserts Provide Enhanced Stability

Tungaloy has expanded its DrillForceMeister and TecMill lines with new drill bodies and milling inserts.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More