Mist Collector Design Fundamentals

Consider design differences when determining what style of mist collector is best for a given application.

Share

Autodesk, Inc.

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View MoreManufacturers use mist collectors on machine tools to provide cleaner air and a better working environment for shopfloor employees. Mist collectors minimize the adverse effects of exposure to metalworking fluids and help shops comply with indoor air quality standards. They also improve in-process part quality by keeping work surfaces clean while reducing maintenance and housekeeping costs.

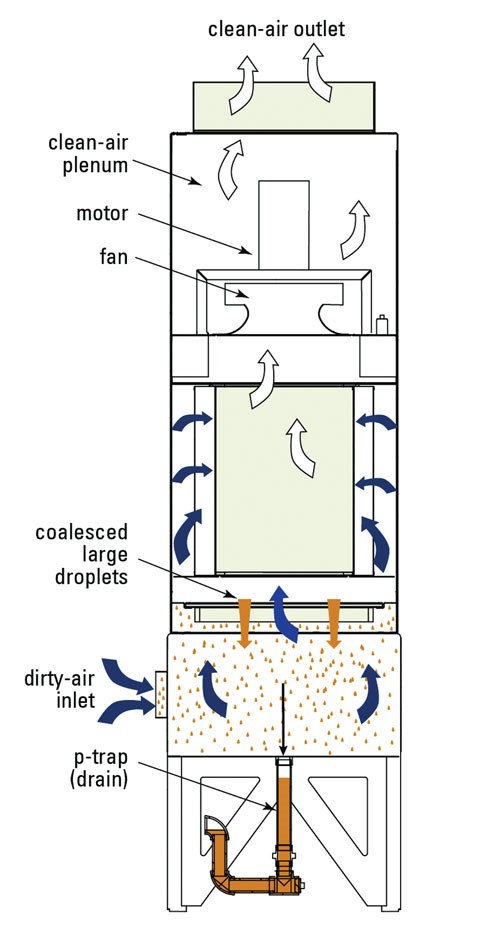

In general, all mist collectors coalesce tiny mist droplets into larger ones and drain the collected coolant to prevent the filtration system from becoming plugged. (Droplets generated during milling and turning operations range in diameter from 2 to 20 microns for water-soluble coolants and from 0.5 to 10 microns for oil-based coolants.) However, there are differences in the ways that particular mist collector systems remove droplets from an airstream. It’s important to consider these distinctions when determining what design is best-suited for a given application.

One common type removes droplets via electrostatic precipitation. These units work by drawing mist-filled air through an ionizer that gives each droplet either a positive or a negative charge. The charged droplets are then captured by collection cells that use alternating high-voltage and grounded plates to attract the charged droplets. The droplets coalesce on the plates and drain out of the collector. Electrostatic precipitation units are advantageous because there are no filters to replace, they consume a relatively low amount of electricity and they offer high efficiency when fully cleaned. That said, they have fallen out of favor with some due to their frequent, arduous maintenance routines. Their internal components must be kept meticulously clean in order to efficiently charge and capture droplets.

Another design relies primarily on inertial separation to remove droplets from an airstream by diverting the airstream around a collection surface inside the unit. Because the droplets in the airstream have momentum, they continue on their path and impact the surface, ultimately coalescing with other droplets and draining. Inertial separators typically do not have primary filters that need to be changed. However, they require regular maintenance to clean contamination from the components. In addition, inertial separation tends to work better on large droplets than small ones because bigger droplets have more mass and momentum. This increases their chance of impacting the collector surface. Inertial separators have sub-par efficiency when droplets are smaller than 2 microns in diameter.

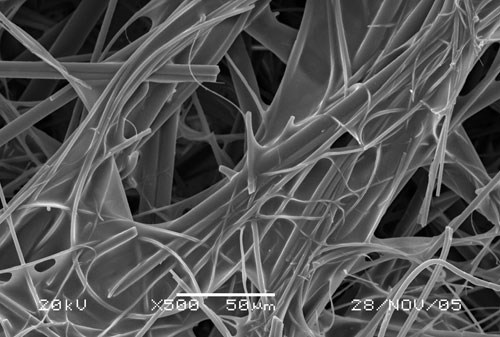

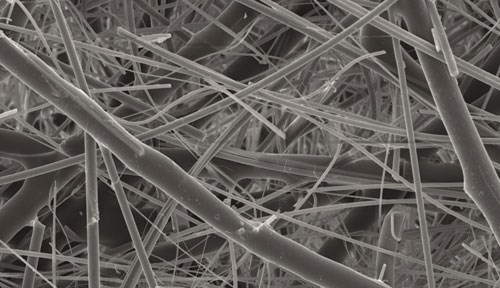

A third type of mist collector uses fibrous filter media to remove droplets. Droplets adhere to the fibers in the filter media and coalesce with other droplets. When a droplet is sufficiently large, gravity pulls it down the fiber to drain. The challenge using this type of collector is balancing the need for both high efficiency and effective draining. High filtration efficiencies can be achieved using small fibers. However, small fibers typically require resin to hold them together, which prevents coalesced droplets from draining effectively. Therefore, filter media using small fibers can become easily plugged with trapped liquid. Conversely, large fibers have good draining characteristics but can compromise the ability of the media to capture small mist droplets.

Such a circumstance is often mitigated by using layers of fiber media. A pre-filter layer with large fibers, mesh or screens captures and drains large droplets while a second or primary layer with smaller fibers accumulates most of the remaining droplets. An optional third layer uses a HEPA or DOP filter for high-efficiency removal of sub-micron-sized droplets. However, if any of these layers are working poorly, the entire mist collector will be ineffective.

This prompted Donaldson Company, a provider of filtration systems and replacement parts for industrial and engine applications, to develop a more consistent way to realize both high efficiency and effective draining using fiber media. The company’s Synteq XP media is an engineered blend of small and large fibers that uses a proprietary, resin-free bonding system. Heat-fusing the surface of larger binding fibers to surrounding micro-glass fibers provides a stable pore structure that improves unit performance and life because no resin blocks the pores. With no resin to compromise effective draining, the media’s small fibers offer higher filter efficiency. In turn, its larger fibers provide good overall support for the structure while maintaining clear drain channels.

About the author: Karen Geronime is a Torit Product Manager at Donaldson Company, Inc.

Related Content

Considerations for Machining Coolant Care

Coolant care can be simply managed if you know where to pay attention and which hazards to look out for.

Read MoreAFT's Semi-Synthetic Coolant Extends Sump Life

Advanced Cool 2200 provides high visibility while machining, keeping the machine and parts clean with no odor issues.

Read MoreHenkel Redefines Industrial Machining and Grinding with Sustainable Metalworking Innovation

With innovative formulation and bio-resistant properties, Henkel’s new semi-synthetic lubricant emerges as a pioneering solution in the machining industry.

Read MoreJorgensen Introduces Sustainable Conveyor, Material Handling, Coolant, Filtration Solutions

IMTS 2024: Jorgensen Conveyer and Filtration Solutions announces a lineup for conveyor, material handling, coolant and filtration solutions, including the EcoFilter80 self-cleaning system, the PermaClean system and others.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.png;maxWidth=150)