Look Beyond Machine Utilization When Installing a Machine-Monitoring System

Connecting machines to a network for production monitoring almost guarantees that utilization will go up, but that’s only the first step toward data-driven manufacturing.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

LMI Aerospace has the word aerospace in its name because that’s the market the supplier serves almost exclusively. This company is a global manufacturer of structural assemblies, kits and components for its diverse aerospace customers. It also provides design engineering services to back up its manufacturing capability (not many machining companies can thrive just by producing parts anymore.)

One of the company’s machining facilities is in Washington, Missouri, near St. Louis, and not far from its corporate headquarters in St. Charles. Three years ago, the Washington facility began actively seeking a monitoring system for its CNC machines in order to check status and collect performance data for analysis. One of the main goals and expectations was to see an improvement in utilization.

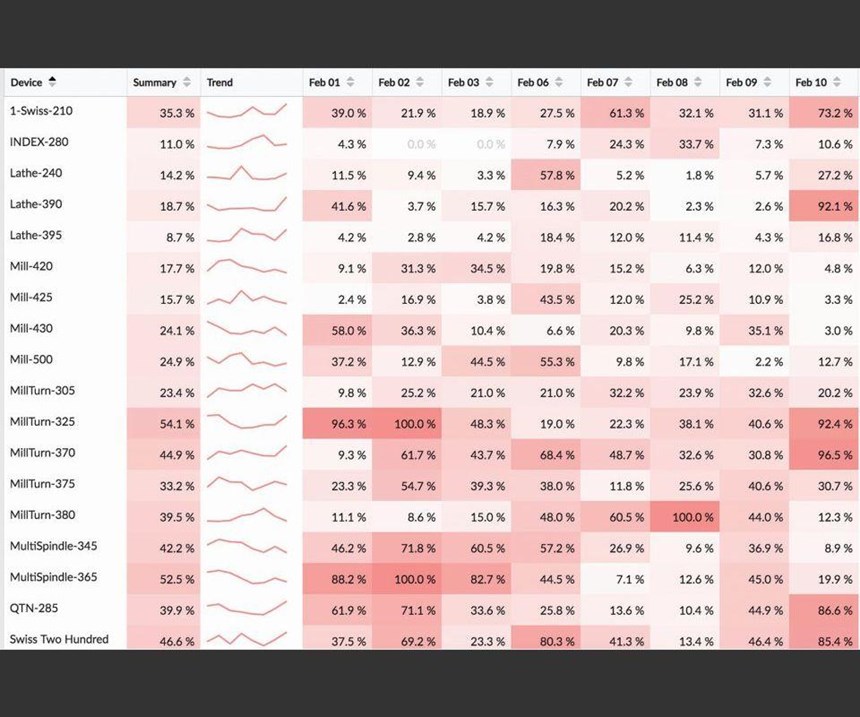

In fact, once key machine performance measures were being shown on the large-screen monitors on the shop floor, utilization increased by about 10 percent right away, largely because machine operators could spot and avoid easy-to-correct causes of unnecessary downtime. But that was only the beginning. LMI saw other value in the data being captured by this machine-monitoring system.

Looking beyond utilization set this facility up for significant reductions in machining costs on key equipment, more efficient machining parameters such as optimal feed rates, more accurate and timely quotes to customers, and other benefits, including even greater improvement in utilization rates after the monitoring system was in sustained use. However, these benefits were contingent on the monitoring system being able to provide insight into processes and put data into a meaningful context. For LMI Washington, machine monitoring was a definitive step toward a much broader move to data-driven manufacturing.

A Global Supplier

Founded in 1948, LMI Aerospace currently has more than 1 million square feet of manufacturing space among its 15 plants in the United States, and Mexico. Worldwide, the company employs around 2,000 people. The firm fabricates, machines, finishes and assembles components that are machined or formed to close tolerances from aluminum, specialty alloys and advanced composite materials. It manufactures more than 40,000 products for large commercial airplanes, business and regional jets, as well as military aircraft.

LMI’s overall machining capabilities range from simple, two-axis turning to complex, simultaneous five-axis milling. Regardless of the type of machine tool involved, the company says it focuses on the latest tooling technology, cutting techniques and machining processes. High-speed machining lines with pallet systems, robotics, lean manufacturing techniques and computerized inspection are implemented throughout its manufacturing facilities.

LMI keenly understands the importance of reliable, streamlined and on-time part production because these are essential to the variety of aerospace kitting services it offers to customers. Assembling kits in house helps facilitate the flow of components to the customer’s assembly line, enabling those customers to keep inventory low and save floor space.

While all of its operations reflect the policies and philosophies of LMI Aerospace, each facility has considerable autonomy and the responsibility to pioneer applications of technology that best support its contribution to the corporate mission. A good example of this is LMI Washington’s early adoption of machine monitoring and the data analytics that it provides. Other LMI plants have also begun testing and implementing networks for machine monitoring. These facilities expect to experience similar benefits.

How Machine Monitoring Helps

Like many machine shops today, the Washington facility has a variety of newer and older CNC equipment. Most of the newer machines are equipped with MTConnect-compliant control units, though several of the legacy machines were installed before this interoperability standard was adopted and their control systems have limited data-generating capability.

The facility had four primary goals for its machine-monitoring initiative:

- Capture accurate utilization metrics.

- Create a work environment that drives performance by displaying the utilization data on the shop floor.

- Generate condition-based email alerts to ensure quick action and prevent extended downtimes.

- Understand part production trends and cycle times through analytics.

To this end, the plant connected 22 machines for data reporting and analysis by Vimana software from System Insights (Berkeley, California). Vimana is a standards-based software solution designed to monitor and manage manufacturing productivity. One of the strengths of this system that attracted LMI Washington is its ability to identify periods of production losses using a sophisticated classification engine. This engine provides users with the information and insight needed to improve utilization, the software developer says. Another essential strength was the ability of this system to establish network connections to many types of control systems, including those locked into proprietary data formats or those capable of generating only limited usable data.

With the system in place, large displays mounted in the machining areas show real-time status of connected machines, including various aspects of machine performance and utilization that can help operators recognize opportunities to improve productivity. Nicholas Mueller, then a systems analyst at LMI Washington and project lead for the machine-monitoring system implementation, says these features accounted for the initial bump up in utilization. “We experienced this 10 percent increase just by displaying Vimana on the shop floor.”

Previously, the production team relied on red-yellow-green stack lights mounted on each machine to assess their status. Now, the monitoring software enables them to view a machine’s status at a glance or check it remotely on a mobile device. The system also alerts them via email to indicate prolonged downtimes—insight that a stack light cannot provide.

Over a sustained period since initial startup, utilization rates have continued to improve. Results of all the machines connected have shown an increase of more than 15 percent, the company says. The best-performing machine has shown improvement of more than 20 percent in average utilization. The palletized lines have also achieved an improvement around 20 percent, which is especially significant because these lines represent a major capital investment in machining capacity, LMI says.

Mr. Mueller points to one reason for these results: The software’s downtime classification capabilities are able to accurately capture the status of the equipment. These classifications include Producing, Standby, Planned Downtime and Unplanned Downtime. The introduction of the Standby status helped LMI tease out the difference between machines that were down and machines that were ready but not at work because of upstream holdups. This granularity in understanding the machine status helped managers prioritize and make effective decisions to improve machine utilization, he says.

Other benefits are also significant. For example, operators have created healthy competition amongst themselves by following the system’s main dashboard, which is displayed on shopfloor monitors. Likewise, customized production rules and alerts based on toolpath feed-rate overrides and rapid override values have led to improved identification of production cycles.

In addition, visibility to actual asset production utilization of machines has enabled LMI to provide more competitive bids to its customers.

Using Part Metrics to Increase Capacity

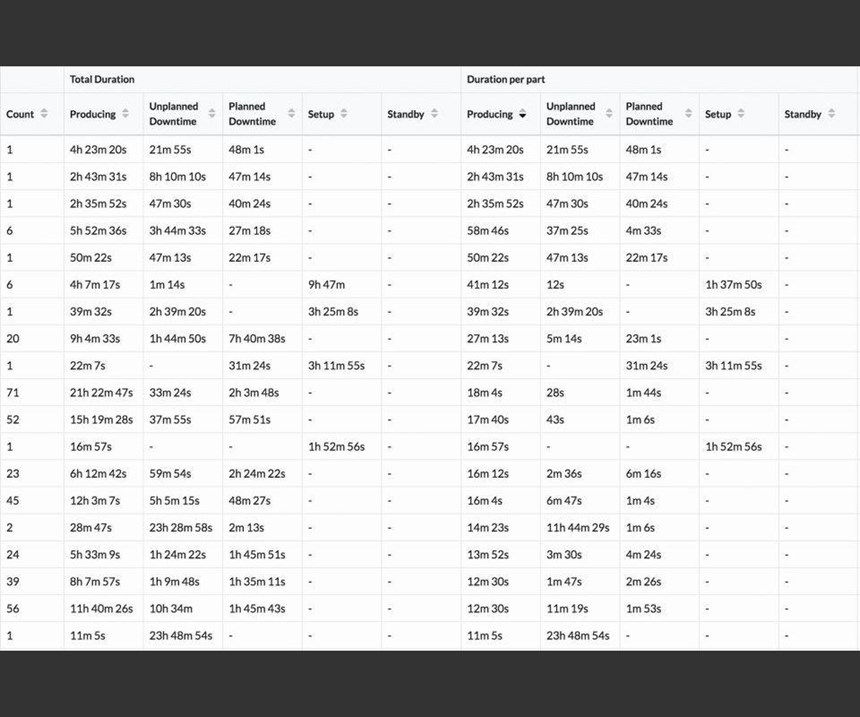

Vimana’s Part Metrics report gives detailed information about how a part was made, including information on the production and setup times involved. LMI Washington has been able to use this report to obtain an accurate part cycle time for its job-costing calculations. Workorders at this facility are typically one week in duration. The total time taken to make a part is compared across three categories—Estimated, CAM Analysis and Actual Runtime. The monitoring software provides actual run time, a calculation which helps improve estimates for upcoming workorders.

Managers use an internal tool called the Capacity Chart to assess how long it actually takes a machine to make a part. Data from the Part Metrics report is populated in the Capacity Chart. Vimana automatically identifies which part is running on the machine by analyzing the G code during run time, and provides the actual amount of time that went into producing each part. The report also identifies planned and unplanned downtime periods associated with the part, along with the time required to set up each part across various machines. This detailed understanding of the actual time required to make a part has improved the company’s ability to accurately determine part cost and have clarity on the true cost per machining hour.

Mr. Mueller notes that on one of the facility’s most valuable five-axis machines, “we were able to identify that the actual cost per machining hour varied from the calculations previously used, helping us reassess our competitiveness in the market.” The software also helped LMI understand how much value was being added by each of its workcenters and the cost of operating those workcenters. This precise information helps make cost estimates and planning more accurate.

Always Moving Ahead

The aerospace industry is constantly changing and evolving. In response, LMI operations must change and evolve to keep ahead of its customers’ needs. At the Washington facility, the machine-monitoring system has to be flexible and dynamic as well. In fact, it has created a growth path for a deeper and broader understanding of what is happening on the shop floor, and provides the facts and figures that enable the plant to make better decisions about these happenings.

This is reflected in the improved utilization rates, for sure, but there seems to be no end to other improvements that can follow new insights into production processes and machine performance. For LMI, this ongoing effort naturally involves Vimana’s Client Services team, which helps adjust the rules by which alerts are issued, how reports are configured and what analytic routines are applied. These are just a few of the ways that the monitoring system can grow and change along with the entire facility.

Related Content

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read More2 Secondary Coordinate Systems You Should Know

Coordinate systems tell a CNC machine where to position the cutting tool during the program’s execution for any purpose that requires the cutting tool to move.

Read More4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read MoreSwiss-Type Control Uses CNC Data to Improve Efficiency

Advanced controls for Swiss-type CNC lathes uses machine data to prevent tool collisions, saving setup time and scrap costs.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)