Five-Axis CAD/CAM Lends a Hand to Prosthetics Manufacturing

By using a five-axis machine and a complementary five-axis release of Visi 20 CAD/CAM software from Vero, one manufacturer reduced setups and established more cost-effective production runs for complex prosthetic components.

Leading shops are often able to help customers establish a more efficient manufacturing process for their new products. This was the case two years ago when UK-based Delta Tooling (Horsham) was approached by RSLSteeper to machine five complex components for the company’s new Bebionic3 prosthetic hand.

The prosthetics specialist asked Delta’s directors Gary Childs and Luke Tetlow to assist in the manufacture of its advanced prosthetic hand, which is used to assist amputees by performing 14 different grips that mimic human movement. RSLSteeper’s initial concept was to cast or mold the hand’s five components, followed by finish-machining operations and then assembly and testing. Instead, Delta Tooling suggested milling the components from billet material, using some of its existing equipment to perform 3+2 machining operations based on programs created using the shop’s Visi 15 CAD/CAM package from Vero Software. That way, preliminary molding and casting processes could be eliminated altogether for more streamlined part production.

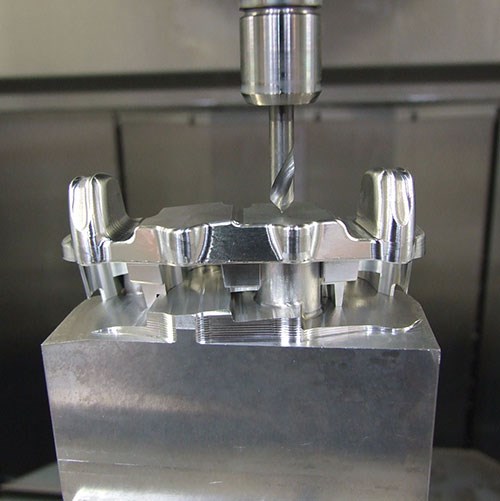

However, as the complexity of the components grew, it soon became clear that Delta required the flexibility of full five-axis machining. Each hand included an aluminum knuckle, a plastic sub-section to which it connects and a complex thumb bracket that enables the opposable thumb to rotate and move backward and forward. In order to machine these tricky parts more effectively, Delta invested in a GF AgieCharmilles Mikron UCP 800 Duro and updated its programming software to the latest five-axis release of Visi 20.

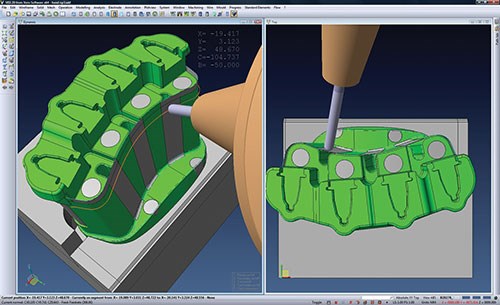

The Visi 20 software enables operators to prepare part geometry for manufacture and create efficient five-axis tool paths. CAD data can be imported into Visi in file formats including STEP, IGES and Parasolid. Various checks are performed on the file to ensure its integrity before laying it out in a way that can produce the component from the machine tool’s point of view. Then the shop assesses the part’s machinability, Mr. Childs explains. As part of that process, he says that running Visi’s machining collision control and kinematic simulation is extremely valuable. “Having just made a major investment in a new five-axis machine, the last thing we want is to cause a collision,” Mr. Childs says. “That’s why we always run full kinematic simulation prior to any production run.”

He notes that another important feature in Visi 20 is the dynamic incremental stock (DIS) command. This command automatically creates the stock model from the uncut material of previous tool paths to be used as reference data for subsequent milling operations. For example, the command enables rough machining on one side of the product, and after it’s turned over, a new machining cycle enables rough machining again—without cutting air, Mr. Childs says. This reduces the machine cycle time and enables the shop to produce the components in a timelier manner.

The Mikron runs almost constantly across two shifts, from 8 a.m. to 2 a.m., manufacturing to a call-off order for RSLSteeper on a monthly basis. It is also used for machining components in additional production runs for Delta’s various motorsport customers.

“The combination of the new five-axis Mikron machine tool and Visi five-axis programming software is making us even more efficient and competitive for all of our customers,” Mr. Child says. “It not only gives a better quality finish on the product, but it means we can manufacture it in a more efficient timescale, thereby reducing the number of setups and producing cost-effective production runs.”

Related Content

Can ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

Read MoreHow this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

Read MoreFearless Five-Axis Programming Fosters Shop Growth

Reinvestment in automation has spurred KCS Advanced Machining Service’s growth from prototyping to low-and mid-volume parts. The key to its success? A young staff of talented programmers.

Read More4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read MoreRead Next

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreInside Machineosaurus: Unique Job Shop with Dinosaur-Named CNC Machines, Four-Day Workweek & High-Precision Machining

Take a tour of Machineosaurus, a Massachusetts machine shop where every CNC machine is named after a dinosaur!

Read MoreIncreasing Productivity with Digitalization and AI

Job shops are implementing automation and digitalization into workflows to eliminate set up time and increase repeatability in production.

Read More