EDMing Beryllium Copper: An Introduction

Beryllium copper offers many benefts to the moldmaker and plastic injection molder, yet questions remain on how to best EDM it, which alloy to specify, where to use it, and is it safe to work with?

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Takumi USA

Featured Content

View More

What Is Beryllium?

Beryllium is a metal which is found in several substances; beryl, bertrandite rock, oil and possibly in the soil in your backyard. It was discovered more than two centuries ago, and has become a valuable component in many items that we use in everyday situations. It is extremely lightweight and hard. Pound for pound it is six times stronger than steel and two thirds the weight of aluminum. I withstands extreme heat and it has excellent thermal properties as a conductor. When used in combination with other metals such as copper, nickel or aluminum, the resulting alloy boasts even better performance properties. One popular alloy is beryllium copper (also known more correctly as copper beryllium). It is used in battery contacts and in electrical connectors for cell phones, for example. FM radios, High Definition TV (HDTV), air bag sensors, fire extinguishers, pacemakers, X-Ray imaging, radar and navigation systems, all depend on beryllium copper or other beryllium alloys for optimum performance and reliability.

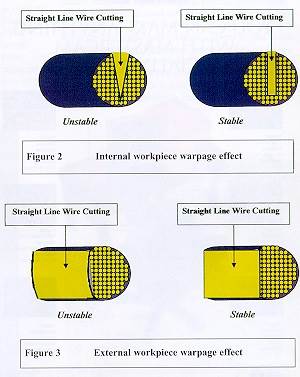

And of course, closer to home, beryllium copper is used in 'problem' molds to reduce cycle time and enhance molded part quality. There are several beryllium copper alloys that are specifically designed for the mold making industry. Figures 1 & 2 (at right) show micro-photographs of pure copper and a copper beryllium alloy.

Beryllium copper alloys are used for their high strength as well as good electrical and thermal conductivities. There are two groups of beryllium copper alloys: High Strength and High Conductivity. The high strength alloys (in cast form) have beryllium concentrations up to 2.7%. The high conductivity alloys contain up to 0.7% (as well as higher amounts of nickel and cobalt). The high strength of the copper beryllium alloys is attained by age hardening or precipitation hardening.

The Moldmaker's Advantage

The main function of an injection mold, beside defining a part's shape, is to remove heat from the plastic as quickly as possible. The mold should be thought of as a heat transfer device, much like an automobile radiator. The faster the mold can transfer heat out of the molten plastic and solidify it, the faster the mold can be run. Reduced cycle time equates to reduced manufacturing cost. This is where copper alloys outperform other metals used for molds. Copper alloys provide the best combination of high thermal conductivity, and hardness for molds used in the plastic industry today. As seen in the Comparison of Mold Alloy Properties Table, Figure 3 (below), hardness and conductivity vary over a range for each material steel, aluminum or copper alloy. For example, copper alloys have thermal conductivities 3 to 9 times greater than a commonly used 420 type stainless steel.

The following is a brief summary of the advantages of using copper alloys in mold design and building:

Thermal Conductivity

A mold design that takes advantage of the superior combination of thermal conductivity and strength of these alloys, results in a more uniform removal of heat from the plastic part. This results in less post-mold warpage and shrinkage. Additionally, shorter cycle times and better dimensional control of the injected plastic part are due in part to better optimized molding parameters. Utilizing beryllium copper alloys in areas such as manifold design, gives the molder more uniform control of the temperature of the plastic melt, with higher quality control.

| Figure 3 - Comparison of Mold Alloys Properties Table | |||

| Description | Thermal Conductivity (Btu/ft2/ft/hr°F) |

Hardness (Rockwell) |

Tensile Strength (ksi) |

| 420 Stainless Steel | 14.4 | C 27-52 | 125-250 |

| H-13 Tool Steel | 14.4 | C 38-54 | 206 |

| P-20 Tool Steel | 22.0 | C 28-50 | 146 |

| 6061 T6 Aluminum | 96.5 | B 60 | 40 |

| Beryllium Copper - High Hardness |

60.6 | C 41 | 190 |

| Beryllium Copper - High Conductivity |

135.0 | B 96 | 110 |

Wear Resistance

Mold life is primarily a function of a mold material's ability to withstand abrasive wear and galling. Beryllium copper alloys have shown excellent wear resistance in injection mold components and cavity inserts. The use of these materials in strategic areas in blow molds (for example), improves parting line maintenance, and provides longer service life.

Corrosion Resistance

The high percentage copper base of these materials provides excellent resistance to hydrochloric acid, carbonic acid, and similar decomposition by-products which can result during the molding process. The molding of poly vinyl chloride (PVC) is potentially corrosive to molds, and is an example where copper alloys could be of advantage to the moldmaker and to the maintenance department.

Machinability

Beryllium copper alloys are readily machinable. In chip making operations, a reduction of 10-25% in machining time, can be seen when compared to tool steels. When EDMing, the materials high thermal conductivity can be a disadvantage when compared to steel. A section devoted to EDMing this material will give some electrode selection tips, and parameters for gaining back some of the additional time that will be lost when EDM machining.

Weldability

There probably isn't a moldmaker out there who hasn't had to repair or alter a mold by welding a section or two. Fortunately, this doesn't present a problem, as these alloys are readily repairable without significant loss of strength to the mold body. Both TIG (tungsten inert gas) and MIG (metal inert gas) processes are recommended here, in combination with a beryllium copper filler rod.

Surface Treatment

Another advantage to the moldmaker is that these materials can be further enhanced by the addition of surface treatments to increase wear resistance, corrosion resistance, and improved part release from the mold surface. This can be achieved with coatings of chrome, electroless nickel, titanium nitride or tungsten disulfide.

Two of the more popular copper alloys, Protherm and Moldmax are manufactured by Brush Wellman, and are designed for the plastic molding industry.

Protherm provides the highest thermal conductivity available in a mold material (other than pure copper). For example, the conductivity is ten times greater than that of steel and twice that of aluminum. It is specially developed for 'problem' molding applications, such as foam processing, hot runner systems, and other applications where maximum heat removal or control is required.

| Material: | Beryllium Copper (Protherm) | ||

| Approx. | Be | Ni | Cu |

| Analysis% | 0.4 | 1.8 | Bal. |

| Condition: | 190 Briness | ||

| Figure 4: Courtesy of Brush Wellman, Elmore, OH | |||

The main properties and benefits for Protherm include:

- Extremely high thermal conductivity

- Excellent corrosion resistance

- Good polishability and machinability

- Good resistance to galling

- Excellent weldability

- Rapid, uniform heat transfer

- Resistance to high temperature i.e. for engineering plastics

- Ability to be coated for higher wear resistance

- Optimum production cycle times

- Reduction or elimination of cooling channels

- Elimination of hot spots

- Improved plastic part quality

- Rapid, uniform heating in hot runners

- Maximum heat transfer in injection nozzle

Moldmax is another alloy that finds applications in areas similar to Protherm, but where strength is a little more important than overall thermal conductivity. In fact, this copper alloy provides strength and wear resistance similar to that of many tool steels. It offers a thermal conductivity three to four times that of steel, and is comparable to aluminum. It is typically specified for blow mold pinch offs, injection mold components and cavity inserts, and hot runner system injection nozzles and manifolds. Recommended applications for Protherm and Moldmax beryllium copper inserts include: Injection molds; RIM molds (reaction injection molds); Nozzle tips; Edge gates and Manifolds for hot runner systems, and when ever short cycle times are important. Protherm is available already heat treated, and no other processing is necessary. Beryllium copper alloys have a content of approximately 0.5% to 2% beryllium.

Application Examples

Copper alloy tooling has been shown to offer a number of advantages to the mold designer and to the injection molder. The excellent thermal conductivity of copper alloys reduces cycle times, and at the same time, can improve part quality. The following examples show how a particular molding problem was solved by thinking beyond the simple question of: Steel or aluminum?

Control of part warpage was the primary objective in this first example. To accomplish this, the main core was specified in a high conductivity beryllium-copper alloy. Decreased cycle time was a secondary bonus advantage.

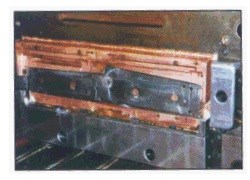

When Whirlpool Corporation tooled their recent new line of dishwashers, their primary objective was to improve on an already high quality product. An innovative technology advance was required to control warpage on deep ribs, and improve straightness and flatness on the exterior of a dishwasher front control bezel. Figure 5 (at right) shows a beryllium copper mold component that replaced the previous type 420 stainless piece.

Various brainstorming approaches to improve on the quality and economics of molding this challenging 24 inch long dishwasher part were discussed. The solution was to use a beryllium copper alloy core, to provide the necessary uniform cooling required to obtain the demanding quality levels. The same part on the previous dishwasher models was very difficult to mold. Meeting the specification of 0.040 inches maximum warp across the edges of the console housing, even with long cycles, was often a hit or miss proposition. The quality improvement of the console housing from the copper alloy core was dramatic! Initial findings during the first several months of production showed no parts exceeded 0.020 inches of warpage, and assembly difficulties were much reduced. While the primary objective of the new tooling was to improve part quality, a 20% reduction in cycle time was realized, due to the improved cooling of the beryllium-copper alloy core. Additionally, sink marks on the Class A surfaces were substantially reduced, markedly improving the aesthetic quality of the finished product. With the sink mark problem resolved, lower injection and pack pressures could be used, resulting in a stress-free part while saving material in each piece produced.

Figure 6 (left) shows how a problem job that was quouted at a 30 second cycle time, and ran in 55 seconds, was saved by the replacement of the tool steel core with that of Moldmax brand beryllium copper.

The results? A 22 second cycle, which translates to a 56% reduction. In addition, the molder received less 'bow-in' of the molded part, which meant that the overall quality was improved, and that the parts were now well within the drawing specifications.

Improved part accuracy is often the welcome byproduct when copper alloys are selected for critical areas of a mold, as shown in this third example.

Figure 7 (right) shows how dimensional accuracy can be improved where tall ribs are a part of the mold design. The P20 steel cores had become so hot that the mold would not make acceptable parts. The ribs were replaced with Moldmax, which also provided the additional benefit of being stronger and harder than the original P20 steel it replaced.

Wire EDMing Beryllium Copper

First, let's start with the easy one. Use standard copper cutting technology provided by your machine manufacturer. End of story. Case closed. No polarity issues or electrode wear con Change to a higher performing wire. There are several choices out there, but first and foremost, look for a wire with high thermal and electrical conductivity (i.e. copper based core, with a coating containing a percentage of zinc).

Sinker EDMing Beryllium Copper

Next comes a tougher application. It is not rocket science, but it does take more care and thought in planning for EDMing beryllium copper than other materials. Fortunately, help is available, either from your OEM applications department, or from the excellent materials provided by Poco Graphite, Inc. (in manual or CD form). Let's look at a typical EDM example to see what the considerations are, the technology that was used, and the electrode material.

Figure 8 (at left), comes from the POCO EDM Reporter newsletter (Volume 1, 1999). Company: MSI Mold Builders Machine: Xermac 80ST Electrode: POLO EDM-C200 Application: Moldmax insert for office equipment mild.

Thin ribs are usually a bear to EDM, especially when they are deep. Add a material like beryllium copper into the mix, and clearly a solid approach grounded in hours of experience is in order. The ribs for this application are 0.035" wide, and were EDMed 1" deep into the Moldmax beryllium copper material. When the electrode complexity increases, such as with this machined X shape, cutting parameter selection is usually an important factor, so as to reduce the number of required electrodes.

A graphite such as POCO EDM 3 might seem like a good first choice for this electrode. But a review of Tables 1-8 (below) will show that EDM C3 would be a better choice, in terms of metal removal rate and lower corner wear. Bother important considerations when EDMing, and especially when EDMing copper-based alloys. For comparative purposes, the appropriate values have been highlighted for 35 peak amp parameters. Notice that the ON times range from a low of 2µs ON to 51&3181;s ON, depending on the desired result.

| Table 1: Moldmax vs. EDM 3, Metal Removal Rate | ||||

| 2 µs ON | 12 µs ON | 51 µs ON | 205 µs ON | |

| 3.5 Peak Amps | 0.015 cu. in./hr. | 0.013 cu. in./hr. | 0.007 cu. in./hr. | 0.002 cu. in./hr. |

| 10 Peak Amps | 0.058 cu. in./hr. | 0.068 cu. in./hr. | 0.104 cu. in./hr. | 0.049 cu. in./hr. |

| 35 Peak Amps | 0.291 cu. in./hr. | 0.447 cu. in./hr. | 0.278 cu. in./hr. | 0.221 cu. in./hr. |

| Table 2: Moldmax vs. EDM C3, Metal Removal Rate | ||||

| 2 µs ON | 12 µs ON | 51 µs ON | 205 µs ON | |

| 3.5 Peak Amps | 0.017 cu. in./hr. | 0.018 cu. in./hr. | 0.007 cu. in./hr. | 0.002 cu. in./hr. |

| 10 Peak Amps | 0.072 cu. in./hr. | 0.158 cu. in./hr. | 0.034 cu. in./hr. | 0.013 cu. in./hr. |

| 35 Peak Amps | 0.263 cu. in./hr. | 0.476 cu. in./hr. | 0.583 cu. in./hr. | 0.495 cu. in./hr. |

| Table 3: Protherm vs. EDM 3, Metal Removal Rate | ||||

| 2 µs ON | 12 µs ON | 51 µs ON | 205 µs ON | |

| 3.5 Peak Amps | 0.007 cu. in./hr. | 0.006 cu. in./hr. | 0.002 cu. in./hr. | 0.0003 cu. in./hr. |

| 10 Peak Amps | 0.032 cu. in./hr. | 0.049 cu. in./hr. | 0.036 cu. in./hr. | 0.013 cu. in./hr. |

| 35 Peak Amps | 0.198 cu. in./hr. | 0.278 cu. in./hr. | 0.363 cu. in./hr. | 0.291 cu. in./hr. |

| Table 4: Protherm vs. EDM C3, Metal Removal Rate | ||||

| 2 µs ON | 12 µs ON | 51 µs ON | 205 µs ON | |

| 3.5 Peak Amps | 0.012 cu. in./hr. | 0.008 cu. in./hr. | 0.0013 cu. in./hr. | 0.0007 cu. in./hr. |

| 10 Peak Amps | 0.052 cu. in./hr. | 0.080 cu. in./hr. | 0.058 cu. in./hr. | 0.014 cu. in./hr. |

| 35 Peak Amps | 0.276 cu. in./hr. | 0.396 cu. in./hr. | 0.506 cu. in./hr. | 0.407 cu. in./hr. |

| Table 5: Moldmax vs. EDM 3, Corner Wear % | ||||

| 2 µs ON | 12 µs ON | 51 µs ON | 205 µs ON | |

| 3.5 Peak Amps | 129.8% | 178.5% | 400.0% | 1250.0% |

| 10 Peak Amps | 133.3% | 135.1% | 157.7% | 232.5% |

| 35 Peak Amps | 121.9% | 107.5% | 119.0% | 120.4% |

| Table 6: Moldmax vs. EDM C3, Corner Wear % | ||||

| 2 µs ON | 12 µs ON | 51 µs ON | 205 µs ON | |

| 3.5 Peak Amps | 111.1% | 120.4% | 188.6% | 769.2% |

| 10 Peak Amps | 119.0% | 113.6% | 142.8% | 277.7% |

| 35 Peak Amps | 102.0% | 89.3% | 97.0% | 113.6% |

| Table 7: Protherm vs. EDM 3, Corner Wear % | ||||

| 2 µs ON | 12 µs ON | 51 µs ON | 205 µs ON | |

| 3.5 Peak Amps | 175.4% | 285.7% | 1250.0% | 1000.0% |

| 10 Peak Amps | 123.4% | 169.4% | 333.3% | 555.5% |

| 35 Peak Amps | 131.5% | 136.9% | 149.2% | 161.2% |

| Table 8: Protherm vs. EDM C3, Corner Wear % | ||||

| 2 µs ON | 12 µs ON | 51 µs ON | 205 µs ON | |

| 3.5 Peak Amps | 126.5% | 192.3% | 1000.0% | 2500.0% |

| 10 Peak Amps | 116.2% | 131.5% | 185.2% | 434.7% |

| 35 Peak Amps | 106.0% | 111.1% | 117.6% | 129.8% |

Speaking of copper alloys (a few paragraphs back), look again at the tables to compare the metal removal rates and corner wear for the Moldmax and the Protherm materials. You will notice that Moldmax cuts faster than Protherm, and that Moldmax is the winner when it comes to reduced corner wear on the electrode. Does that mean that Moldmax is better than Protherm? Not necessarily so. For the answer to that question, you would need to review the suitability of each mold material for its intended application.

Let us now get back to the EDMing challenge referred to in Figure 8. The customer's solution? Keep the benefits associated when using graphite, but combine it with copper impregnated into and throughout the electrode, and you have the winning combination. The customer did exactly that, and chose a copper impregnated electrode material, POCO EDM C200. The parameters selected for this job were: 40 amps (peak), 50 microseconds ON time and 30 micro-seconds OFF time. External jet flushing was used with electrode cycling every 3 seconds. Total EDM time was 2 hours.

The Allegations: Truth or Fiction?

And that brings a central question. Is beryllium copper safe to handle and EDM in the shop? That all depends on who you ask, and of course, how the material is handled and machined. As you might have guessed, there is probably no simple answer. However, there is plenty of material available on the web and from your local supplier, to answer any questions that you may have on this subject. It is outside the scope of this article to cover this question fully and completely. Here is a summary from the Moldmax web site: "Moldmax and Protherm are copper beryllium alloys engineered specifically for the plastic processing industry. Copper beryllium is safe to use in mold components for plastic processing. Handling copper beryllium in solid form poses no special health risk. Like many industrial materials, beryllium-containing materials may pose a health risk if recommended safe handling practices are not followed. Inhalation of airborne beryllium may cause a serious lung disorder in susceptible individuals. The Occupational safety and health Administration (OSHA) has set mandatory limits on occupational respiratory exposures. Read and follow the guidance in the Material Safety Data Sheets (MSDS) before working with this material."

Is There Beryllium Copper In Your Future?

It should be if you are serious about building molds. Does this mean that every mold is a candidate for this material? Obviously not, but it also means that if you have been shying away from using beryllium copper inserts and components because you heard 'baaad' things about it, perhaps now you can rest assured. Knowledge about beryllium materials, combined with practical metalworking techniques and good housekeeping guidelines to help protect your workers, may just give you the edge when designing your next EDM mold, or when trying to solve that unexpected molding problem.

The author offers his special thanks to Poco Graphite, Inc. and Brush Wellman for their assistance.

This article brought to you with the permission of EDM Publications, Inc., publisher of EDM Today, with offices at 230 West Parkway, Unit 3-1, Pompton Plains, New Jersey 07444. Copyright © 2000 by EDM Publications, Inc. Our thanks to the staff of EDM Today for their assistance.

Related Content

Ballbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreHow to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreRead Next

Cryogenic Treatment Enhances Stability For Wire EDM Operation

In the world of Wire EDM professionals, the mission is very similar to NASA's, in minimizing scrap rate and in maximizing quality (i.e. meeting customer specifications). That is the challenge to each Wire EDM operator and tool designer.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)