Custom Tool Storage System Simplifies Setups

Investing in a presetter and additional toolholders helped this manufacturer of custom industrial machinery eliminate mistakes during the tool setup and offsetting process. However, taking full advantage of these investments required a custom, in-house-designed tool storage system that enables efficient management and storage of the shop’s large array of cutting tools.

In manufacturing, the easiest thing to make is a mistake. That’s a driving philosophy at Qsine Corporation, a manufacturer of custom industrial machinery in Calgary, Alberta. With this mindset, the company designs processes with the primary goal of preventing mistakes, as opposed to focusing on specific methods deemed to be the “correct” way to do things. “To some, this seems like a play on words, as the two concepts seem like the same thing,” explains Kevin Saruwatari, Qsine’s owner and president. “However, anyone experienced in manufacturing knows that while there is typically more than one way to do something right, there are always thousands of ways to screw it up.”

Recent efforts to address problems with tool setup and offsetting provide an example of this approach in action. With few employees tasked with a great deal of work, distractions during the setup process led operators to accidentally punch in the wrong offset numbers or even to neglect offsetting entirely. To prevent these mistakes, the company took steps to move offsetting and tool setup to the front of the process, before any on-machine work. Specifically, it invested in an external presetter and enough toolholders to keep all its cutters mounted, thus avoiding the need to change cutters in and out of holders.

The remedy worked. Moreover, the shop found that the price of the many collets and holders required to keep tools mounted is cheaper than breaking down assemblies after every job. Likewise, using the presetter is faster than offsetting at the machine. However, perhaps the most important investment in the shop’s efforts to address these issues is a custom tool storage system that helps manage the whole process. Designed by Mr. Saruwatari and manufactured primarily in-house, the system ensures that the shop’s tools are always visible and easily accessible when operators need them.

Qsine does mostly custom, short-run work for a variety of industries, although defense and energy jobs have constituted the largest portion of business for the past 5 years or so, Mr. Saruwatari says. Now considered mostly a fabrication shop, the company has nonetheless stayed true to its roots as a design and engineering enterprise. “We don’t really have products here. They’re more like projects—a lot of what we do really looks like prototyping,” he explains. “People come to us with a problem, or they’ve got an idea for a machine that they think will solve a problem in their industry. We do a lot of design work, and depending on where customers are in the process, we often create the original CAD files.”

Mr. Saruwatari and his nine employees operate out of an 11,000-square-foot facility. The shop uses two CNC machines: a four-axis Okuma Cadet-Mate VMC with a CAT40 spindle and a nine-axis Okuma MacTurn 250 turn-mill with a Capto spindle. Most production runs involve less than 10 pieces, and very few are repeat jobs.

The nature of this work requires the shop to stock a large number of tools, most of which are used relatively infrequently. As a result, tool storage was haphazard at best—cutter assemblies were stashed in seemingly random drawers, across tabletops and wherever else the shop could find space. “We had our tool offsets figured out, and we had our tools mounted. But for that whole system to work, we needed a place to put the tools.” Mr. Saruwatari says. “With the collection we have here, that was a big problem.”

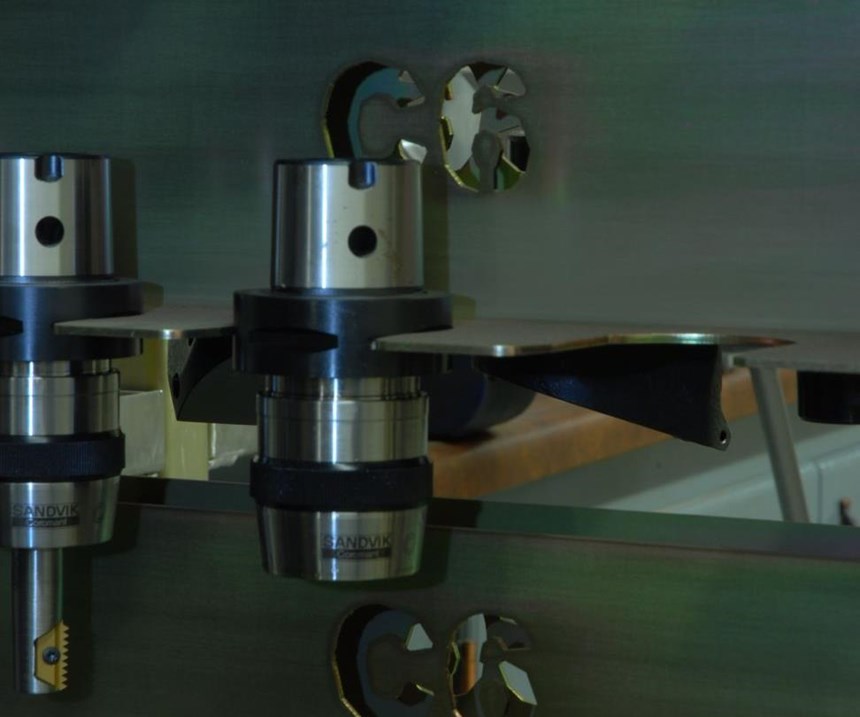

Seeking a solution, the shop scoured the market, but found nothing that met its needs. So, armed with the in-house design knowledge, forming and welding equipment, and the seed of an idea, Qsine set out to develop its own custom storage system. Top priorities for the system were sufficient capacity to accommodate the shop’s large number of CAT40 and Capto tool assemblies; high visibility so operators could locate cutters quickly and easily; and a “tool-down” storage configuration, as opposed to most commercial units in which tools sit on their tapers.

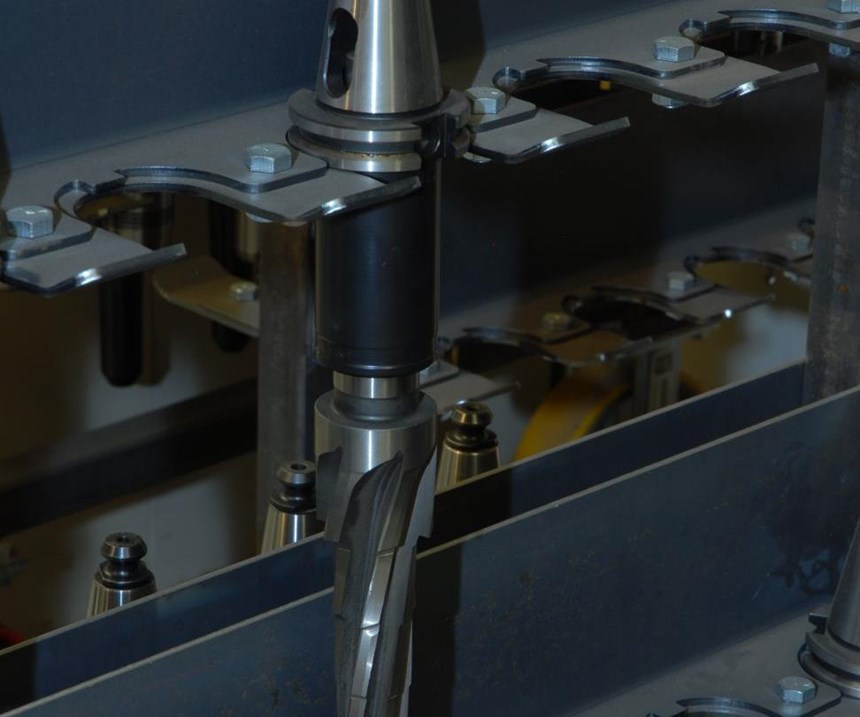

Within a few days, the shop had developed a CAD model of the proposed system, and the first unit rolled off the production line within a month. Colloquially referred to at Qsine as the “Tool Rack,” the system consists of a series of vertical racks with protruding horizontal shelves that hold the tool assemblies. Wheels that run within channels in the floor and ceiling enable each rack to be pulled in and out like a drawer. As a result, the racks can be spaced close together to keep the overall system compact.

Compared with a standard tool cart, which might have three or four layers, the tall, compact racks extend storage from floor to ceiling and can thus accommodate a significantly larger number of tools, Mr. Saruwatari says. While standard carts that can be wheeled directly to a machine might be useful for high-production operations, the Tool Rack better suits Qsine’s purposes, he adds. The system’s configuration also ensures that all tools are easily visible and accessible.

Moreover, the company uses a significant number of long, heavy tools for deep-hole drilling, machining cavities in hydraulic valves and other operations. The ability to vary shelf spacing on each rack enables efficient storage of such tools. This is also a primary reason why Mr. Saruwatari insisted on storing assemblies tool-down—standard configurations make such tools top-heavy, he says. “The CAT40 tool racks or carts I found commercially all sat the toolholder in a pocket on its taper. This is an unstable position for many of my tools,” he explains. “Likewise, the commercial racks for Capto are also in this configuration, and the short Capto tri-lobe is really not well-suited to this design, in my opinion.”

The Tool Rack’s design continues to evolve. One significant development is that the whole system is now modular, as newer units use bolt-on shelves rather than the fixed, welded shelves that characterize the first units the shop produced. This allows the shop to reconfigure the system on-the-fly to accommodate tools with varying lengths, for example, or to switch a given rack from CAT40 tools to Capto and vice-versa. Another improvement is the use of magnetic labels to ensure tools are put in the proper slots when operators are finished with them. These labels can be moved around as-needed if the shop needs to rearrange its tools.

The shop originally started with five racks and still has plenty of room to expand the system, Mr. Saruwatari says. “Investing in toolholders and a presetter were the first steps in reducing tooling and offset related mistakes. The tool rack is an investment that helps us manage the whole process,” he concludes. “It may sound funny, but the rack helps us manage risks and allows us to grow our toolroom, which is critical to shop performance.”

Related Content

Form Tapping Improves Tool Life, Costs

Moving from cut tapping to form tapping for a notable application cut tooling costs at Siemens Energy and increased tool life a hundredfold.

Read MoreGrooving Attachment Streamlines Operation by 75%

A grooving attachment enabled Keselowski Advanced Manufacturing to reduce cycle times by over 45 minutes on a high-value, high-nickel part feature.

Read MoreHow to Troubleshoot Issues With Tool Life

Diagnosing when a tool is failing is important because it sets an expectation and a benchmark for improvements. Finding out why gives us a clue for how to fix it.

Read MoreShoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

Read MoreRead Next

Tool Storage System Standardizes Setup

Faced with time-consuming setups and tool handling, hydraulic manifold manufacturer Apollo Machinery set out to develop its own compact tool storage and tracking system. In the process, the shop not only increased its own efficiency, but also developed a product that it says could set a standard for CNC machine setup.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreIMTS 2024: Trends & Takeaways From the Modern Machine Shop Editorial Team

The Modern Machine Shop editorial team highlights their takeaways from IMTS 2024 in a video recap.

Read More