CNC Programming Software Maximizes Five-Axis Capability

By incorporating new CNC programming software to make full use of its new five-axis machining capabilities, Bob Lewis Machine Co. has reduced setups and programming time.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Increasing capabilities doesn’t end with the purchase of a new machine. In fact, integrating a new machine often can lead to the discovery of other improvements that need to be made throughout the manufacturing process. For instance, when Gardena, California-based Bob Lewis Machine Co. purchased two five-axis CNC machines, it soon realized that its CNC programming software was not taking full advantage of the machines’ capabilities. New software enabled the company’s five-axis machines to realize their full potential while reducing setups on complicated aerospace applications.

Founder Bob Lewis started the company in 1975 in his Torrance, California garage with a Bridgeport mill, a chucker and three drill presses. After receiving supplier approval from AirResearch (now Honeywell), the company began to grow. In 1986, the contract machining shop moved into its current 10,000-square-foot facility, which has been managed by Jeff Lewis since Bob’s 2001 retirement. The shop houses a comprehensive CNC programming department to support the growing number of CNC machining centers.

A major milestone for Bob Lewis Machine was the purchase of two five-axis CNC machining centers with large work envelopes that enable access to five sides of the part for complete machining in one or two setups. The company’s SNK Nissin Max 4101i-P40 features a rigid 17-inch trunnion table that provides the swing area necessary for machining larger parts. Its Fadal VMC 4020 features a flame-hardened integrated boxway construction, Steinmeyer ETA+ dual-mounted ballscrews and spindle speeds ranging from 8,000 to 10,000 rpm.

Soon after taking delivery, the company discovered that the CNC programming software it had been using could not generate code that worked on the Nissan machine. On a recommendation, Mr. Lewis purchased Delcam’s FeatureCAM CNC programming package solution because it could automate many aspects of the programming process, which would speed and simplify the job. The software now runs on six networked computers to generate programs for all 16 of the shop’s CNC machining centers. The software enables programmers to access more of the part in only one or two setups. For instance, programmers can drill holes at angles, machine surfaces at compound angles and machine canted features. By avoiding multiple fixturings, feature relationships can be held more closely and the shop is able to save both time and money.

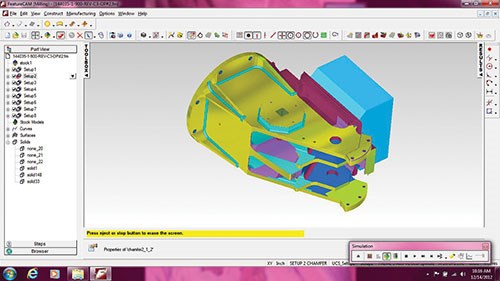

The combination of five-axis machining and new software has helped Bob Lewis Machine realize expanded capabilities in complex part applications. One example is a tricky part with features oriented at many different angles, including compound angles. The customer provided a blueprint and a STEP file with the part geometry. Mercelo Hermosillo, operations manager, says STEP files strip out the intelligence of the native CAD file. “They convert feature definitions in a meaningful jumble of geometric entities,” he says. Importing the geometry into FeatureCAM solved this problem. The software automatically reconstructed the intelligence of the original CAD file by recognizing features such as holes, counterbores, bosses, chamfers and fillets. Once FeatureCAM identified a list of features, Mr. Hermosillo reviewed them and made several changes, such as merging, splitting, adding or deleting features. This eliminated the need to work with each individual surface, enabling him to program a much smaller number of features instead.

Mr. Hermosillo then defined the 8- by 8- by 12-inch workpiece and set up a roughing operation to quickly remove large volumes of metal. He used a C axis roughing strategy in which the X, Y, Z and C axes are used to position the tool and workpiece for machining. He then selected a 1-inch carbide insert end mill for the initial roughing pass. FeatureCAM recommended feeds and speeds for this and each subsequent operation based on its knowledge database. Mr. Hermosillo accepted some of these recommendations and modified others.

He invoked FeatureCAM’s rest machining capability to determine all areas of the part that could be safely machined by this tool without gouging. Rather than tracing the entire outline of the part, the tool path rapid-traversed around areas that did not require machining to reduce cycle time. With a 1/8-inch depth of cut and 60-percent stepover, the initial roughing operation took about 2 hours.

For the next pass, he selected a 1/4-inch, high speed steel square end mill and again used rest machining to identify areas of the remaining stock that could be safely machined. In addition to two different sizes of ballnose end mills for semi-finishing and finishing, Mr. Hermosillo also used several drills and taps. The machine’s fourth and fifth axes were used to position the workpiece at the proper angle during semi-finishing and finishing. In the first setup, five sides of the workpiece were machined, with the sixth side machined in a second setup.

Once the part program was complete, Mr. Hermosillo used simulation to ensure the part was produced to specifications and used simulation to look for ways to reduce cycle time and avoid collisions. By increasing cutting speed and depth of cut in several areas, he was able to reduce the machining time to about 18 hours rather than the originally estimated 20. What would have taken two months to program and produce six of the parts using conventional three-axis methods now takes only four days to program and 14 days to machine, he says.

By taking full advantage of five-axis capabilities, Mr. Lewis says the company has reduced setups on complicated aerospace parts from an average eight to ten setups to only two. Programming time has also been reduced, he says. As a result, the shop is able to cut delivery time by an average of 60 percent.

Related Content

Continuous Improvement and New Functionality Are the Name of the Game

Mastercam 2025 incorporates big advancements and small — all based on customer feedback and the company’s commitment to keeping its signature product best in class.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreCutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreCan AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)