A Modulated Approach to Deep-Hole Drilling

After years spent trying to overcome the challenges it had encountered drilling a deep hole in a tiny workpiece, this shop finally discovered the solution in a technology called Modulation Assisted Machining.

Share

Hwacheon Machinery America, Inc.

Featured Content

View MoreIt has long been a metalworking conundrum: How do you drill a small hole more than 10xD deep into tool steel without chips clogging the path and breaking your cutting tool? Peck cycles that periodically retract the drill to clear the hole of the long chip ribbons produced via traditional machining are one approach, but that adds time to the process and can reduce tool life since it basically means restarting the cut each time drilling resumes. Drill flutes have also been designed to address this situation, but with varying degrees of success since the problem has as much to do with effective chip formation and evacuation as it does the constant and measured application of coolant to the work interface.

The ideal solution would be a method that completes the hole in one pass, delivering coolant to the drill tip at a uniform rate and cutting chips to a consistent size that can clear the passage being machined without adhering to its outer wall, or clinging to the tool itself. You would also want it to reliably reproduce good results, once they’ve been dialed in.

Enter a technology called Modulation Assisted Machining (MAM), which delivers these benefits and more, according to Bob O’Callaghan, general manager of Whitney Tool Co. Inc. The cutting tool manufacturer had spent 10 years seeking a solution to this hole-drilling challenge before discovering—and adopting—the process. “The part being drilled was in our catalog, and people still wanted it, so we had no choice but to continue making it using the same old tools and methods, despite a nearly 50-percent failure rate,” he says. “That’s why we were so relieved when we discovered this technology.”

Drilling Dilemma

Based in Bedford, Indiana, Whitney Tool was founded in 1970 as a private label manufacturer. It wasn’t long before the company decided to begin manufacturing its own products. What began as a four-page product catalog has since expanded to nearly 100 pages filled with milling cutters, counterbores, deburring tools, countersinks and tapered end mills. In addition to these stock items, more than 40 percent of the company’s revenue is derived from custom tooling. Whitney Tool also manufactures tap and drill extensions, including a miniature version—4 inches in length with either a 1/8-, 3/16- or 1/4-inch shank in more than 100 drill sizes—that was creating its deep hole drilling dilemma. The specific challenge in this instance involved creating a hole in the integral collet of the extension. When the compression cap is tightened, this feature holds the drill firmly in place. The company was concerned with drilling holes with widths ranging from 0.0135 to 0.0280 inch, and it was struggling to reach depths of 3/16 inch without breaking a tool. MAM technology now allows the shop to reach that depth consistently, even plunging to 7/16-inch deep on some special orders.

In describing the problems Whitney Tool was encountering before employing MAM, Mr. O’Callaghan points to an extremely high fallout rate. Nearly half of the extensions machined were relegated to the scrap bin due to drill failure within the cut. Breakage was caused by a number of factors, all related to the way deep-hole drilling has traditionally been performed.

Since the fluted drill required to machine the miniature extension is too small for through-coolant, it’s easy to imagine how constant contact with the relatively dry cutting surface would generate a great deal of heat. Also, the chips that such a drill generates are long and thin, spiraling from the base of the cut and along the length of the drill flutes toward the shaft. Combined, the heat in the passage and the shape of the chips lead them to periodically build up and begin adhering to the walls of the workpiece, impeding the drill’s forward progress. Peck drilling is often used in such instances. This involves occasionally pausing the operation during the cycle to retract the drill, clearing the hole, and allowing coolant to flood and enter the workspace, though not in a uniform manner. As one can imagine, this is both time-consuming and potentially damaging to the cutting tool. Mr. O’Callaghan knows, because Whitney Tool tried every conceivable remedy.

“Along with peck drilling, we experimented with different drill-point grinds and flute configurations, and we even invested in a more accurate CNC lathe with precision spindle bearings to reduce runout and vibration for better process control,” he says. “But none of it provided the answer we were looking for.”

After investing far more time than they’d expected—nearly a decade, at that point—and with no viable resolution to the problem in sight, Whitney Tool resigned itself to working too hard and wasting too many cutting tools on a drilling operation that failed far too often.

Oscillation Innovation

At about that same time, a company called M4 Sciences LLC was beginning to gain traction in manufacturing facilities around the world with its proprietary Modulation Assisted Machining technology, marketed under the name TriboMAM. M4 Sciences was launched by CEO James Mann and Brian Gootee, COO and secretary, within Purdue University’s business incubator and is located at the Purdue Research Park in West Lafayette, Indiana. As it so happens, Scott Baker, operations manager at Whitney Tool, is a graduate of the university, where he studied industrial engineering.

“I’m a big supporter of Purdue, and I stay involved with its engineering program,” Mr. Baker says. “I was a member of the advisory council for the Technical Assistance Program (TAP), which helps Indiana manufacturers solve machining problems they encounter, and that’s where I heard about this company called M4 Sciences. We’d spent so long trying to figure out our deep hole drilling problem, so it was exciting to find out there was a new technology available. We decided to look into it.”

The prospects of the technology were intriguing. In a sense, the TriboMAM system uses a controlled feed rate modulation (oscillation in the feed rate direction)—that could be described as a peck cycle on steroids. Rather than a drilling cycle periodically interrupted by retracting the tool to clear the hole to allow for the entry of coolant, when the drill is mounted in the ER collet of the small cylindrical TriboMAM, which is inserted into the machine’s tool block, it delivers hundreds of “pecks” per second. The drill oscillates in the feed direction, uniformly interrupting the surface being cut to form small chips in “discrete events” that are easily evacuated from the hole. This eliminates the need for traditional peck cycles involving complete withdrawal of the drill. The oscillating action in MAM also allows coolant to reach the tip of the cutting tool

during each oscillation cycle, lowering the heat generated so that the tool can remain in the cut through completion.

“The test run went very well,” Mr. O’Callaghan recalls, “and we quickly realized that we’d found our solution. Once we’d made the decision to invest in the technology, it was just a matter of installation and training. After all the headaches this had caused, you can imagine how eager we were to get started.”

Easy Installation

That didn’t take long, as it turned out. As Phil Fassnacht, vice president of sales and marketing at M4 Sciences points out, the TriboMAM hardware is fairly unobtrusive. The MEC controller, which accepts both metric and standard measurements, typically rests on top of the machine tool.

For more complex processes, it can be integrated into the machine control. It is programmed to match the machine tool spindle speed, feed rate, number of drill flutes and the diameter of the drill being used.

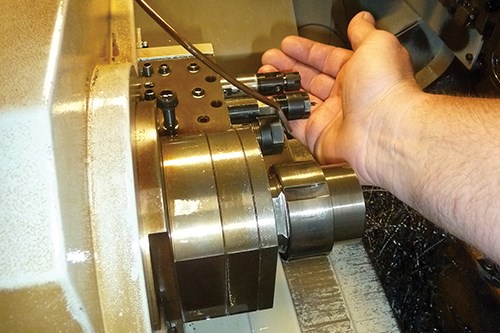

The TriboMAM mounts inside the machine enclosure in the same way as an ER collet extender, with flexible power cables that can be routed in a number of different ways. The vibrations returned to the machine are minimal—less than turning with an interrupted cut, the company says, or using live tooling for milling operations. Specialty coolants are not required, and either a flood or high-pressure through-tool system can be utilized. With such a small drill that would be damaged by high pressures, Whitney Tool opted for a flood coolant system. Installation of the complete TriboMAM system was completed in less than an hour, and the controller’s commands are both uncomplicated and intuitive. The optimal drilling settings were quickly determined, and they can be easily adjusted to suit drilling of various dimensions.

There are other benefits of the MAM system, as well. “In terms of the machining process itself, TriboMAM provides controlled chip formation and evacuation, and improved lubrication of the cutting interface lowers friction and the resulting heat,” Mr. Fassnacht says. “Plus cycle times are reduced since the drilling feed rate is increased two to five times.”

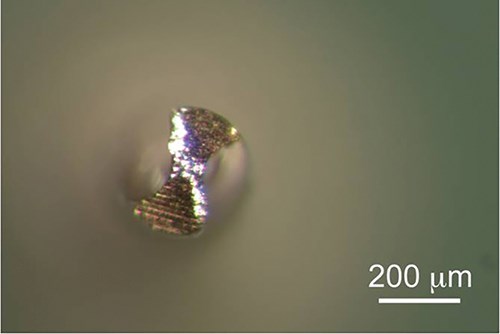

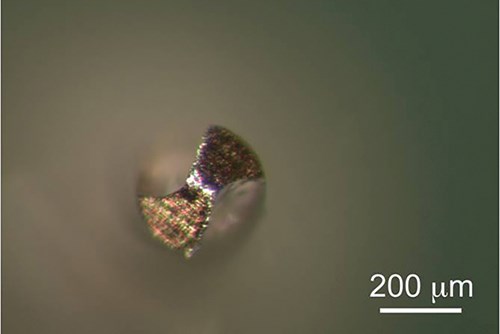

It’s easy to see the improvement in magnified images of metal buildup on drill tips that have been used in a standard peck cycle scenario compared with a TriboMAM-optimized drill with no peck cycle. After 250 parts have been machined, the drill used in conventional machining already shows both material accumulation and significant wear, while the edges of the optimized drill are much cleaner and well-defined after processing the same number of parts. Even after 500 parts, the optimized cutting tool is remarkably intact and free of buildup (see photos).

While Whitney Tool’s application involves high-speed steel, TriboMAM has also been tested and proven effective working with other difficult-to-drill materials, including copper, cast iron (compact graphite iron), super alloys, stainless steel and titanium, according to Mr. Fassnacht. Allowing for application variances, material surface finishes and hole tolerances have proven to be unaltered, or many times improved when compared to the baseline process.

These factors combine to increase tool life by as much as 10 times, since there is less breakage and wear, the company says. And while cycle times have been reduced, being able to complete the operation successfully in one pass with a single tool is the primary improvement over past experiences. In addition, no specialized tooling is required, allowing for the use of carbide gun drills, coolant-fed carbide twist drills, and screw-machine or jobber drills.

Mr. O’Callaghan says these savings can be applied directly to the company’s bottom line. “Any time you can get more productivity out of a commodity item like a cutting tool, you’re going to make more money in the long run. And I say that as a manufacturer of cutting tools. We want ours to last as long as possible, just like our customers do.”

Cultivating Curiosity

More than a year has passed since TriboMAM was installed on Whitney Tool’s Citizen L20 Swiss-type lathe, and all the frustration that had built up over the years related to failed experimentation has dissipated like the heat carried away by a well-formed chip. Originally considered to be a “quality issue,” according to Mr. O’Callaghan, the solution to this deep-hole drilling challenge has delivered far more benefits than originally envisioned.

“This company has been around for more than 45 years, and our customers have come to rely on the cutting tools we manufacture,” he says. “So it’s not as easy as removing a product from the catalog because we’re having trouble machining it. We were willing to continue manufacturing these drill extenders for the benefit of our customers, even though the process of making them was so problematic. Now, producing this part is efficient, streamlined, and more importantly, our failure rate has dropped well below 10 percent. And that’s a number we can live with.”

Mr. O’Callaghan says that, as trite as it may sound, manufacturers can no longer afford to get in the rut of ceasing to seek out new technologies. “A lot of machining methods are referred to as ‘tried and true,’ and for good reason,” he says, adding that the company has already identified additional applications for MAM technology, such as drilling through-coolant holes on its 9-inch tap extensions. “But there are new technologies constantly being developed that you need to know about. That can happen by staying curious or attending trade shows, but mostly it’s about reaching out and asking for help when you hit a wall. That’s what we did, and it really paid off.”

Related Content

Toolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.

Read MoreBriquetting Manufacturer Tools Up for Faster Turnaround Times

To cut out laborious manual processes like hand-grinding, this briquette manufacturer revamped its machining and cutting tool arsenal for faster production.

Read MoreSelecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

Read MoreHigh-Feed Machining Dominates Cutting Tool Event

At its New Product Rollout, Ingersoll showcased a number of options for high-feed machining, demonstrating the strategy’s growing footprint in the industry.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)